Honed tube is well known as hydraulic cylinder tube in many industries. This is because honed tubes are the most important materials of manufacturing hydraulic cylinders.

Read more

The API SPEC 5L specification provides standards for pipe suitable for use in conveying gas, water, and oil in the natural gas and oil industries.

Read more

Mild steel is the type of carbon steel where it contains very low amounts of carbon. Approximately, it is 0.16–0.29% by weight.

Read more

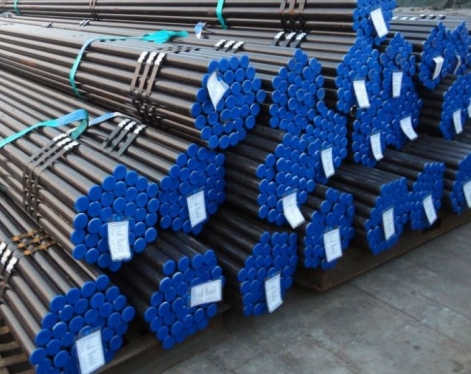

Black steel pipe is manufactured as seamless which makes it a better type for gas transportation and fire sprinkler systems since it can prevent fire better than galvanized pipe.

Read more

When iron is mixed with nickel and chromium, we get stainless steel, which is hard and does not rust. Steel can also be galvanized. Galvanized steel is more preferred from anticorrosion point of view.

Read more

The wall thickness of the seamless pipe is made up of the Schedule series (40, 60, 80, 120) and is connected to the weight series (STD, XS, XXS).

Read more