The steel sheet piling is a kind of iron product, so the anti-corrosion work during use is very important, so how to complete the anti-corrosion work of the steel sheet piling?

Read more

Pressure vessel flanges are common parts of pressure vessels. They are widely used in petrochemical, electric power, atomic energy, light industry and other industrial fields, and they are the basic components for connecting various pressure vessel components.

Read more

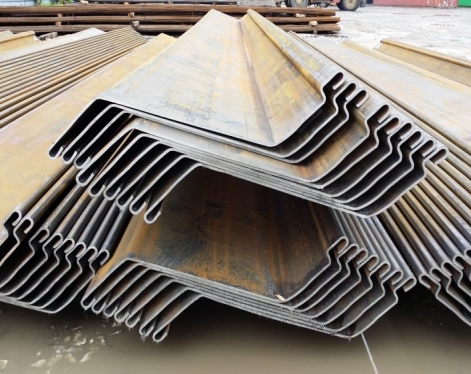

U-shaped steel sheet piles have U-shaped cores in their appearance, but there are also other shapes such as Z-shaped and in-line shapes

Read more

The zinc coating is thick, with detailed, uniform and non-porous crystals, and excellent corrosion resistance; The zinc layer obtained by electroplating is relatively pure, and it corrodes slowly in the mist of acid, alkali, etc., and can effectively maintain the steel substrate;

Read more

The pipe spools is prefabricated to reduce on-site installation costs and provide higher product quality. They usually have flanges to connect to other spools.

Read more

After the deep foundation pit is backfilled, the steel sheet pile shall be removed to facilitate repeated use. Before pulling out the steel sheet piles, the sequence of pulling out methods, pile pulling conditions and soil holes should be studied carefully and scientifically.

Read more