As the most critical pressure-bearing and heat-transferring component in a boiler system, boiler tubes operate under high temperature, high pressure, highly corrosive media, and complex combustion atmospheres for extended periods. Their corrosion status directly affects the boiler's safe operation, energy efficiency, and service life. Practice shows that boiler tube corrosion is not caused by a single factor, but rather by the combined effects of materials, media, water quality, combustion conditions, and operation and maintenance. Boiler tubes are a type of steel tubes, and boiler tubes are generally made of seamless tubes.Therefore, boiler tube corrosion protection must be implemented throughout the entire process, from design and material selection, surface protection, chemical water treatment, operation control, and shutdown maintenance.

Internal corrosion is most commonly caused by steam-water oxidation, alkaline corrosion, acid corrosion, electrochemical corrosion caused by dissolved oxygen and carbon dioxide, and hydrogen damage. Among these, the destruction of the protective film in alkaline environments, the penetration of the passivation film by chloride ions, and the infiltration of hydrogen atoms into grain boundaries significantly reduce the mechanical properties of boiler tubes and induce early failure.

Externally, high-temperature corrosion, sulfide corrosion, reducing atmosphere corrosion, and sulfuric acid dew point corrosion are particularly prominent, especially under conditions of burning high-sulfur fuels or SNCR denitrification, where sulfates, sulfides, and complexation reactions accelerate the damage to the metal substrate.

Before construction, methods such as sandblasting, shot blasting, or pickling are typically used to remove oxide scale, rust, and contaminants, achieving a surface roughness of Sa2.5 or St3.0, forming a uniform roughness that provides a reliable mechanical bonding foundation for the coating.

For protective coatings, high-temperature ceramic coatings, graphene anti-corrosion coatings, and high-temperature resistant sealing and far-infrared radiation coatings are widely used. These coatings possess high density, excellent acid and alkali resistance, good wear resistance, and high thermal conductivity. They not only effectively isolate corrosive media but also improve heat transfer conditions on heated surfaces, reducing the risk of ash buildup and acid condensation.

During construction, strict control of the mixing ratio, number of spray coats, film thickness, and curing conditions is crucial. High-pressure airless spraying with multiple coats is typically employed to ensure a uniform coating, free of runs and pinholes.

Furthermore, arc spraying technology, with its advantages of high bonding strength, high spraying efficiency, and strong on-site adaptability, has also become an important means of corrosion protection for boiler heated surfaces.

Meanwhile, strict water quality management is equally indispensable. Feedwater must be adequately deoxygenated and maintained at a suitable pH level. The alkalinity, phosphate, and chloride ion content in the boiler water should be properly controlled. Continuous blowdown and regular testing are crucial to prevent salt concentration and localized corrosion.

Regarding fuel management, properly blending high-sulfur and low-sulfur coal and monitoring coal quality parameters in real time can significantly reduce the corrosion risk caused by sulfur fluctuations.

Simultaneously, deploying online gas monitoring devices in easily corroded areas to monitor indicators such as CO and H₂S in real time, and linking them with the airflow regulation system, can significantly shorten corrosion early warning and response times.

Furthermore, developing appropriate soot blowing strategies and controlling the load increase/decrease rate to avoid drastic temperature fluctuations on heating surfaces are also important operational measures to delay boiler tube corrosion.

By cleaning accumulated ash, maintaining a dry and well-ventilated boiler, and regularly starting and stopping the blowers, the risk of external corrosion can be effectively reduced.

For the boiler interior, wet pressure maintenance or dry maintenance can be selected depending on the shutdown period to prevent the corrosion of metal surfaces by oxygen, moisture, and impurities. Simultaneously, regular inspection and drainage of safety valves and the discharge system can prevent potential hazards caused by localized water accumulation and freezing.

I. Overview of Boiler Tube Corrosion Mechanisms

Boiler tube corrosion can be broadly classified into internal corrosion and external corrosion.Internal corrosion is most commonly caused by steam-water oxidation, alkaline corrosion, acid corrosion, electrochemical corrosion caused by dissolved oxygen and carbon dioxide, and hydrogen damage. Among these, the destruction of the protective film in alkaline environments, the penetration of the passivation film by chloride ions, and the infiltration of hydrogen atoms into grain boundaries significantly reduce the mechanical properties of boiler tubes and induce early failure.

Externally, high-temperature corrosion, sulfide corrosion, reducing atmosphere corrosion, and sulfuric acid dew point corrosion are particularly prominent, especially under conditions of burning high-sulfur fuels or SNCR denitrification, where sulfates, sulfides, and complexation reactions accelerate the damage to the metal substrate.

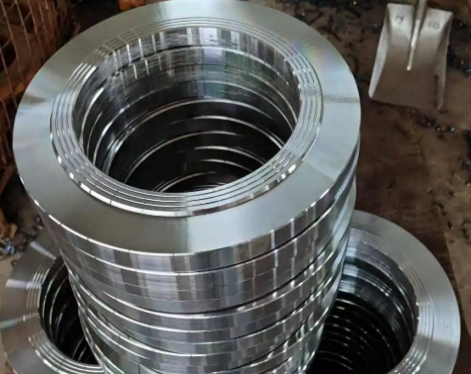

II. Surface Treatment and Coating Corrosion Protection Technology

The first line of defense for boiler tube corrosion is surface treatment and protective coatings. Practice has shown that the quality of surface treatment can affect the corrosion protection life by more than 50%.Before construction, methods such as sandblasting, shot blasting, or pickling are typically used to remove oxide scale, rust, and contaminants, achieving a surface roughness of Sa2.5 or St3.0, forming a uniform roughness that provides a reliable mechanical bonding foundation for the coating.

For protective coatings, high-temperature ceramic coatings, graphene anti-corrosion coatings, and high-temperature resistant sealing and far-infrared radiation coatings are widely used. These coatings possess high density, excellent acid and alkali resistance, good wear resistance, and high thermal conductivity. They not only effectively isolate corrosive media but also improve heat transfer conditions on heated surfaces, reducing the risk of ash buildup and acid condensation.

During construction, strict control of the mixing ratio, number of spray coats, film thickness, and curing conditions is crucial. High-pressure airless spraying with multiple coats is typically employed to ensure a uniform coating, free of runs and pinholes.

Furthermore, arc spraying technology, with its advantages of high bonding strength, high spraying efficiency, and strong on-site adaptability, has also become an important means of corrosion protection for boiler heated surfaces.

III. Chemical Corrosion Prevention and Water Quality Control

Chemical corrosion prevention is the core measure for corrosion protection inside boiler tubes. By adding boiler-specific scale and corrosion inhibitors, a dense and stable protective film can be formed on the metal surface, simultaneously inhibiting scale formation and dispersing corrosion products. Its mechanism of action includes complexation solubilization, lattice distortion, dispersion stabilization, and passivation film protection, significantly reducing the rate of scaling and corrosion.Meanwhile, strict water quality management is equally indispensable. Feedwater must be adequately deoxygenated and maintained at a suitable pH level. The alkalinity, phosphate, and chloride ion content in the boiler water should be properly controlled. Continuous blowdown and regular testing are crucial to prevent salt concentration and localized corrosion.

IV. Corrosion Control Measures During Operation

The boiler's operating conditions have a decisive impact on the corrosion rate. Optimizing combustion organization and properly controlling the oxygen content and air distribution ratio in the furnace can effectively prevent the formation of reducing atmospheres and high-temperature sulfidation corrosion. Refined burner maintenance and reducing tangential deviation and combustion misalignment are important means to reduce localized high-temperature corrosion.Regarding fuel management, properly blending high-sulfur and low-sulfur coal and monitoring coal quality parameters in real time can significantly reduce the corrosion risk caused by sulfur fluctuations.

Simultaneously, deploying online gas monitoring devices in easily corroded areas to monitor indicators such as CO and H₂S in real time, and linking them with the airflow regulation system, can significantly shorten corrosion early warning and response times.

Furthermore, developing appropriate soot blowing strategies and controlling the load increase/decrease rate to avoid drastic temperature fluctuations on heating surfaces are also important operational measures to delay boiler tube corrosion.

V. Corrosion Prevention and Maintenance During Boiler Shutdown

During boiler shutdown, the corrosion rate of boiler tubes is often higher than during operation, making shutdown maintenance particularly crucial.By cleaning accumulated ash, maintaining a dry and well-ventilated boiler, and regularly starting and stopping the blowers, the risk of external corrosion can be effectively reduced.

For the boiler interior, wet pressure maintenance or dry maintenance can be selected depending on the shutdown period to prevent the corrosion of metal surfaces by oxygen, moisture, and impurities. Simultaneously, regular inspection and drainage of safety valves and the discharge system can prevent potential hazards caused by localized water accumulation and freezing.