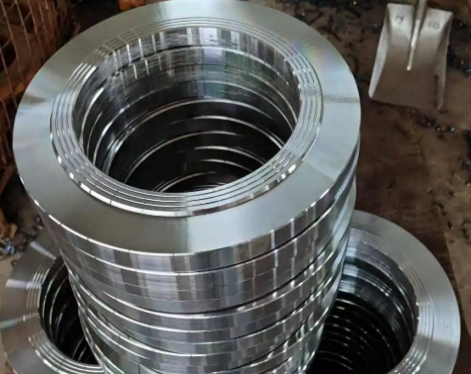

Mechanical tubes, as the name suggests, are closely related to mechanical structures. They are long strips of steel with a hollow cross-section and no seams around them, essentially a type of seamless pipe. Mechanical tubes are mainly used to manufacture mechanical parts and structural frames. For example, the cylinder block of a car engine and the spindle of a machine tool both rely on seamless mechanical tubes to provide strong support and a reliable structural foundation, ensuring the stable operation of the entire system.

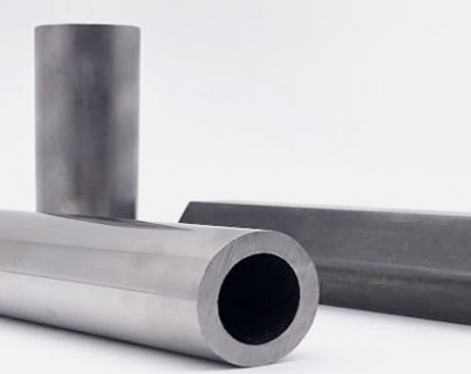

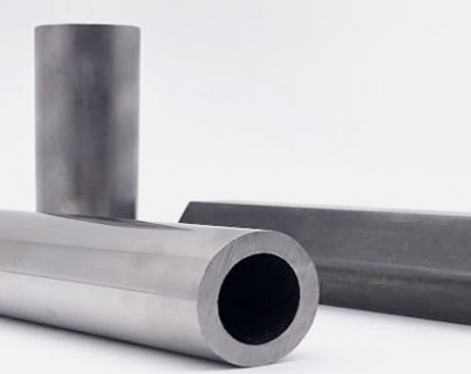

Hydraulic tubes are the "blood vessels" of the hydraulic system, specifically used to transmit working media such as hydraulic oil. In the hydraulic systems of construction machinery such as excavators and cranes, hydraulic tubes are responsible for transporting high-pressure oil to various actuators, such as hydraulic cylinders and hydraulic motors, to achieve precise movement of mechanical parts and powerful power output.

Feature comparison

1. Strength and pressure resistance

Mechanical tubes are usually made of high-quality steel and have high strength and pressure resistance. They can withstand large external forces and internal pressures. In the structural support of heavy machinery, mechanical tubes can stably withstand huge weights and complex stresses to ensure the safe operation of the machinery.

Hydraulic tubes also have high strength, but their pressure resistance varies depending on the specific working conditions and the material used. Hydraulic tubes used in high-pressure hydraulic systems are made of high-strength alloy materials and undergo special processing to meet the requirements of use in high-pressure environments.

2. Ease of installation

The installation of mechanical tubes is relatively easy and can generally be completed through common methods such as welding and threaded connections. The professional skills required of installers are relatively low. In the assembly of small machinery, ordinary workers can easily complete the installation of mechanical tubes.

However, due to the complex connection method of hydraulic tubes and extremely high requirements for sealing performance, the installation process is relatively cumbersome and usually requires professional technicians to operate. During the installation of large hydraulic equipment, technicians need to strictly follow the specifications for pipe connection, sealing and debugging to ensure the normal operation of the hydraulic system.

3. Cost difference

The production process of mechanical tubes is relatively mature and the cost of raw materials is low, so the overall cost is relatively affordable. It is suitable for large-scale production scenarios that are more sensitive to cost, such as general machinery manufacturing. Due to its high precision and good sealing requirements, hydraulic tubes have a more complex production process and higher material performance requirements, so the cost is relatively high. They are often used in high-end equipment and precision hydraulic systems that have high performance requirements and are not very sensitive to cost.

4. Service life

Under normal use and maintenance, mechanical tubes have a long service life and can operate stably in relatively harsh environments. For example, the mechanical tubes in construction machinery can maintain good performance even under long-term exposure to wind, sun, and high-intensity work. Hydraulic tubes can have a long service life under proper maintenance conditions, but they have strict requirements on the working environment and working conditions. Harsh working conditions such as high temperature, high pressure, and high vibration will accelerate the aging and wear of hydraulic pipes and shorten their service life.

Application field comparison

Mechanical tube application scenarios

Mechanical tubes are widely used due to their high strength and structural stability:

1. In long-distance oil and natural gas pipelines, they are responsible for oil and gas transportation and ensuring a stable energy supply.

2. In the process pipeline network of petrochemical enterprises, a complex system is formed to realize the transportation and processing of chemical raw materials and products.

3. In urban centralized heating networks, hot water is transmitted for heating, and its corrosion resistance and pressure resistance ensure long-term stable operation of the system.

Hydraulic tube application scenarios

Hydraulic pipes are suitable for fields that require high power transmission and control precision.

Military field (aircraft, ships): As a key component of the hydraulic system, it transmits high-pressure oil to achieve precise control of flight attitude and rapid response of weapon systems, ensuring equipment performance and reliability;

Civilian field:

1. Coal Industry: Transmits power to hydraulic supports, ensuring safe and efficient coal mining.

2. Construction Machinery (excavators, cranes, etc.): Provides power output and precise motion control to meet construction needs.

3. Automotive: Used in power steering and braking systems, ensuring driving safety and controllability.

Read more: Mechanical Tube Size

Hydraulic tubes are the "blood vessels" of the hydraulic system, specifically used to transmit working media such as hydraulic oil. In the hydraulic systems of construction machinery such as excavators and cranes, hydraulic tubes are responsible for transporting high-pressure oil to various actuators, such as hydraulic cylinders and hydraulic motors, to achieve precise movement of mechanical parts and powerful power output.

Feature comparison

1. Strength and pressure resistance

Mechanical tubes are usually made of high-quality steel and have high strength and pressure resistance. They can withstand large external forces and internal pressures. In the structural support of heavy machinery, mechanical tubes can stably withstand huge weights and complex stresses to ensure the safe operation of the machinery.

Hydraulic tubes also have high strength, but their pressure resistance varies depending on the specific working conditions and the material used. Hydraulic tubes used in high-pressure hydraulic systems are made of high-strength alloy materials and undergo special processing to meet the requirements of use in high-pressure environments.

2. Ease of installation

The installation of mechanical tubes is relatively easy and can generally be completed through common methods such as welding and threaded connections. The professional skills required of installers are relatively low. In the assembly of small machinery, ordinary workers can easily complete the installation of mechanical tubes.

However, due to the complex connection method of hydraulic tubes and extremely high requirements for sealing performance, the installation process is relatively cumbersome and usually requires professional technicians to operate. During the installation of large hydraulic equipment, technicians need to strictly follow the specifications for pipe connection, sealing and debugging to ensure the normal operation of the hydraulic system.

3. Cost difference

The production process of mechanical tubes is relatively mature and the cost of raw materials is low, so the overall cost is relatively affordable. It is suitable for large-scale production scenarios that are more sensitive to cost, such as general machinery manufacturing. Due to its high precision and good sealing requirements, hydraulic tubes have a more complex production process and higher material performance requirements, so the cost is relatively high. They are often used in high-end equipment and precision hydraulic systems that have high performance requirements and are not very sensitive to cost.

4. Service life

Under normal use and maintenance, mechanical tubes have a long service life and can operate stably in relatively harsh environments. For example, the mechanical tubes in construction machinery can maintain good performance even under long-term exposure to wind, sun, and high-intensity work. Hydraulic tubes can have a long service life under proper maintenance conditions, but they have strict requirements on the working environment and working conditions. Harsh working conditions such as high temperature, high pressure, and high vibration will accelerate the aging and wear of hydraulic pipes and shorten their service life.

Application field comparison

Mechanical tube application scenarios

Mechanical tubes are widely used due to their high strength and structural stability:

1. In long-distance oil and natural gas pipelines, they are responsible for oil and gas transportation and ensuring a stable energy supply.

2. In the process pipeline network of petrochemical enterprises, a complex system is formed to realize the transportation and processing of chemical raw materials and products.

3. In urban centralized heating networks, hot water is transmitted for heating, and its corrosion resistance and pressure resistance ensure long-term stable operation of the system.

Hydraulic tube application scenarios

Hydraulic pipes are suitable for fields that require high power transmission and control precision.

Military field (aircraft, ships): As a key component of the hydraulic system, it transmits high-pressure oil to achieve precise control of flight attitude and rapid response of weapon systems, ensuring equipment performance and reliability;

Civilian field:

1. Coal Industry: Transmits power to hydraulic supports, ensuring safe and efficient coal mining.

2. Construction Machinery (excavators, cranes, etc.): Provides power output and precise motion control to meet construction needs.

3. Automotive: Used in power steering and braking systems, ensuring driving safety and controllability.

Read more: Mechanical Tube Size