The role of boiler tubes in the energy industry

Boiler tubes are indispensable key components in the energy industry and are widely used in thermal power generation, nuclear power generation, chemical industry, petroleum refining, metallurgy and other industrial fields. As the core component of the boiler system, the main functions of the boiler tube are to transfer heat, transport media (such as water, steam, etc.) and withstand high temperature and high pressure working environment. In the energy production process, the quality and performance of boiler tubes directly affect the efficiency, safety, and economy of the entire system. This article will discuss in detail the basic functions, application areas, technical requirements, and importance of boiler tubes in the energy industry.

The basic functions of boiler tubes

1. Heat transfer

One of the primary functions of boiler tubes is heat transfer. In thermal power plants, boiler tubes generate high-temperature flue gas from the combustion of coal, natural gas, or other fuels. This heat is transferred through the boiler tube walls to the water or steam within the tubes, converting the heat into steam energy that drives the steam turbine to generate electricity. The heat transfer efficiency of boiler tubes directly affects the thermal efficiency and energy utilization of the boiler.

2. Media transportation

Boiler tubes are channels for transporting water, steam, or other media. In a boiler system, water is heated in the tubes and converted into high-temperature, high-pressure steam. This steam is then transported through pipes to the turbine, driving the generator to generate electricity. Boiler tubes must possess excellent sealing properties and pressure resistance to ensure the safe transportation of media.

3. Withstand high temperature and high pressure

Boiler tubes must withstand high temperatures and high pressures during operation. For example, in supercritical and ultra-supercritical thermal power generation units, operating temperatures can reach over 600°C and pressures exceeding 25 MPa. Therefore, boiler tubes must possess excellent resistance to high temperatures and high pressures to ensure safe system operation.

Application areas of boiler tubes in the energy industry

1. Thermal power generation

Thermal power generation is the primary application area for boiler tubes. In coal-fired, gas-fired, and oil-fired power plants, boiler tubes are used in the evaporator, superheater, and reheater, among other components, and they perform the crucial task of heating water into steam. With advances in power generation technology, supercritical and ultra-supercritical units are placing even higher demands on the performance of boiler tubes.

2. Nuclear power generation

In nuclear power plants, boiler tubes (also known as steam generator tubes) transfer heat generated by the nuclear reactor to the water in the secondary circuit, generating steam to drive the turbines that generate electricity. Due to the extremely high safety requirements of nuclear power plants, boiler tubes must possess excellent corrosion resistance and radiation resistance.

3. Chemical and petroleum refining

In the chemical and petroleum refining industries, boiler tubes are used in equipment such as furnaces, reactors, and heat exchangers, fulfilling heating, cooling, and media transport tasks. These industries place high demands on boiler tubes for corrosion resistance and high-temperature resistance.

4. Metallurgical industry

In the metallurgical industry, boiler tubes are used in blast furnaces, hot blast furnaces, and waste heat recovery systems to recover and utilize industrial waste heat and improve energy efficiency.

Technical requirements for boiler tubes

1. Material properties

Boiler tube materials must possess excellent resistance to high temperatures, high pressures, corrosion, and creep. Commonly used materials include carbon steel, alloy steels (such as 15CrMo and 12Cr1MoV), and stainless steels (such as 304 and 316L). Heat-resistant alloy steels (such as T91 and T92) and nickel-based alloys (such as Inconel 625) are also used in supercritical and ultra-supercritical units.

2. Manufacturing process

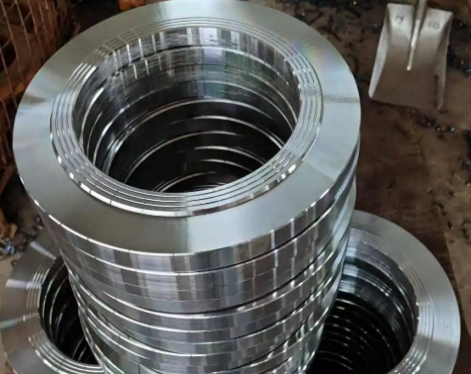

Boiler tube manufacturing processes include seamless and welded steel tube production. Seamless steel tubes offer higher strength and pressure resistance and are commonly used in high-temperature and high-pressure environments. Welded steel tubes, manufactured using high-frequency welding or submerged arc welding, are less expensive and are suitable for medium- and low-pressure environments.

3. Quality inspection

Quality inspection of boiler tubes includes chemical composition analysis, mechanical property testing, non-destructive testing (such as ultrasonic testing and radiographic testing), and hydrostatic testing to ensure they meet service requirements.

Importance of boiler tubes in the energy industry

1. Improve energy efficiency

The heat transfer efficiency and high-temperature resistance of boiler tubes directly impact the thermal efficiency of the boiler. High-performance boiler tubes can reduce heat loss, improve energy efficiency, and lower fuel consumption and carbon emissions.

2. Ensure system securityBoiler tubes operate under high temperature and pressure. Leakage or bursting can lead to serious safety accidents. High-quality boiler tubes can effectively avoid such problems and ensure the safety and stability of energy production.

3. Reduced maintenance costs

Corrosion-resistant and high-temperature-resistant boiler tubes extend the life of the equipment, reducing the need for repairs and replacements, thereby lowering maintenance costs.

4. Driving technological advancement

As the energy industry evolves towards higher efficiency and cleaner production, boiler tube technology is also advancing. For example, supercritical and ultra-supercritical units place higher demands on boiler tubes, driving the development of heat-resistant alloy steels and new manufacturing processes.

Conclusion

As core components in the energy industry, boiler tubes play an irreplaceable role in heat transfer, media transport, and withstanding high temperatures and high pressures. Their performance and quality directly impact the efficiency, safety, and economic viability of energy production. With the continuous advancement of energy technology, boiler tubes will develop towards higher performance, greater intelligence, and greater environmental friendliness, providing crucial support for the sustainable development of the energy industry.

Read more: Performance of Boiler Tubes at High Temperatures

Boiler tubes are indispensable key components in the energy industry and are widely used in thermal power generation, nuclear power generation, chemical industry, petroleum refining, metallurgy and other industrial fields. As the core component of the boiler system, the main functions of the boiler tube are to transfer heat, transport media (such as water, steam, etc.) and withstand high temperature and high pressure working environment. In the energy production process, the quality and performance of boiler tubes directly affect the efficiency, safety, and economy of the entire system. This article will discuss in detail the basic functions, application areas, technical requirements, and importance of boiler tubes in the energy industry.

The basic functions of boiler tubes

1. Heat transfer

One of the primary functions of boiler tubes is heat transfer. In thermal power plants, boiler tubes generate high-temperature flue gas from the combustion of coal, natural gas, or other fuels. This heat is transferred through the boiler tube walls to the water or steam within the tubes, converting the heat into steam energy that drives the steam turbine to generate electricity. The heat transfer efficiency of boiler tubes directly affects the thermal efficiency and energy utilization of the boiler.

2. Media transportation

Boiler tubes are channels for transporting water, steam, or other media. In a boiler system, water is heated in the tubes and converted into high-temperature, high-pressure steam. This steam is then transported through pipes to the turbine, driving the generator to generate electricity. Boiler tubes must possess excellent sealing properties and pressure resistance to ensure the safe transportation of media.

3. Withstand high temperature and high pressure

Boiler tubes must withstand high temperatures and high pressures during operation. For example, in supercritical and ultra-supercritical thermal power generation units, operating temperatures can reach over 600°C and pressures exceeding 25 MPa. Therefore, boiler tubes must possess excellent resistance to high temperatures and high pressures to ensure safe system operation.

Application areas of boiler tubes in the energy industry

1. Thermal power generation

Thermal power generation is the primary application area for boiler tubes. In coal-fired, gas-fired, and oil-fired power plants, boiler tubes are used in the evaporator, superheater, and reheater, among other components, and they perform the crucial task of heating water into steam. With advances in power generation technology, supercritical and ultra-supercritical units are placing even higher demands on the performance of boiler tubes.

2. Nuclear power generation

In nuclear power plants, boiler tubes (also known as steam generator tubes) transfer heat generated by the nuclear reactor to the water in the secondary circuit, generating steam to drive the turbines that generate electricity. Due to the extremely high safety requirements of nuclear power plants, boiler tubes must possess excellent corrosion resistance and radiation resistance.

3. Chemical and petroleum refining

In the chemical and petroleum refining industries, boiler tubes are used in equipment such as furnaces, reactors, and heat exchangers, fulfilling heating, cooling, and media transport tasks. These industries place high demands on boiler tubes for corrosion resistance and high-temperature resistance.

4. Metallurgical industry

In the metallurgical industry, boiler tubes are used in blast furnaces, hot blast furnaces, and waste heat recovery systems to recover and utilize industrial waste heat and improve energy efficiency.

Technical requirements for boiler tubes

1. Material properties

Boiler tube materials must possess excellent resistance to high temperatures, high pressures, corrosion, and creep. Commonly used materials include carbon steel, alloy steels (such as 15CrMo and 12Cr1MoV), and stainless steels (such as 304 and 316L). Heat-resistant alloy steels (such as T91 and T92) and nickel-based alloys (such as Inconel 625) are also used in supercritical and ultra-supercritical units.

2. Manufacturing process

Boiler tube manufacturing processes include seamless and welded steel tube production. Seamless steel tubes offer higher strength and pressure resistance and are commonly used in high-temperature and high-pressure environments. Welded steel tubes, manufactured using high-frequency welding or submerged arc welding, are less expensive and are suitable for medium- and low-pressure environments.

3. Quality inspection

Quality inspection of boiler tubes includes chemical composition analysis, mechanical property testing, non-destructive testing (such as ultrasonic testing and radiographic testing), and hydrostatic testing to ensure they meet service requirements.

Importance of boiler tubes in the energy industry

1. Improve energy efficiency

The heat transfer efficiency and high-temperature resistance of boiler tubes directly impact the thermal efficiency of the boiler. High-performance boiler tubes can reduce heat loss, improve energy efficiency, and lower fuel consumption and carbon emissions.

2. Ensure system securityBoiler tubes operate under high temperature and pressure. Leakage or bursting can lead to serious safety accidents. High-quality boiler tubes can effectively avoid such problems and ensure the safety and stability of energy production.

3. Reduced maintenance costs

Corrosion-resistant and high-temperature-resistant boiler tubes extend the life of the equipment, reducing the need for repairs and replacements, thereby lowering maintenance costs.

4. Driving technological advancement

As the energy industry evolves towards higher efficiency and cleaner production, boiler tube technology is also advancing. For example, supercritical and ultra-supercritical units place higher demands on boiler tubes, driving the development of heat-resistant alloy steels and new manufacturing processes.

Conclusion

As core components in the energy industry, boiler tubes play an irreplaceable role in heat transfer, media transport, and withstanding high temperatures and high pressures. Their performance and quality directly impact the efficiency, safety, and economic viability of energy production. With the continuous advancement of energy technology, boiler tubes will develop towards higher performance, greater intelligence, and greater environmental friendliness, providing crucial support for the sustainable development of the energy industry.

Read more: Performance of Boiler Tubes at High Temperatures