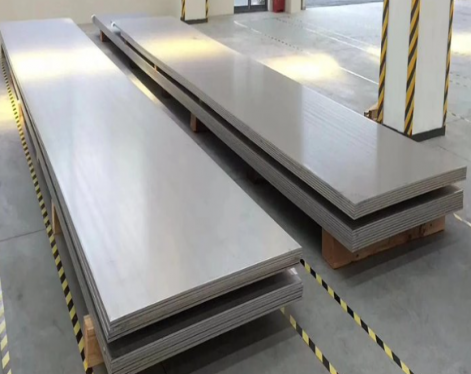

ASTM A240 316/316L stainless steel plate is a high-performance material widely used in industries requiring excellent corrosion resistance, strength and workability. This specification covers flat-rolled plates manufactured to the ASTM A240 / ASME SA240 standard for stainless steel grade

316 and its low-carbon variant 316L.

What Is ASTM A240 316/316L Stainless Steel Plate?

ASTM A240 defines requirements for chromium-nickel-molybdenum alloy stainless steel plates intended for use in pressure vessels, structural components and corrosive environments. Grade 316 offers superior general corrosion resistance, while 316L (low carbon) improves weldability and reduces carbide precipitation during fabrication. Dual-certified 316/316L plates combine the benefits of both grades.

In ASTM A240, type 316 and 316L is a chromium nickel austenitic steel, Element molybdenum addition can enhances corrosion resistance of stainless steel, which is the main factor that 316/316l is more corrosion resistant than 304/304l. When 316L steel of low carbon content is only a little higher than 316 steel on strength level. So sometimes grade 316l is almost the same as 316 grade. Another difference, 316l can be used for weld treatment as it contains lower carbon.

ASTM A240 316/316L stainless steel plate Chemical Composition

The chemical makeup of ASTM A240 316 and 316L plates ensures excellent performance in harsh conditions, especially in chloride and acidic environments such as marine, chemical processing and petrochemical applications.

| Chemical Composition of 316/316L steel |

| Element |

316 |

316L |

| Carbon |

0.08 |

0.030 max |

| Chromium |

16.0-18.0 |

16.0-18.0 |

| Nickel |

10.0-14.0 |

10.0-14.0 |

| Molybdenum |

2.00-3.00 |

2.00-3.00 |

| Manganese |

2 |

2 |

| Silicon |

0.75 |

0.75 |

| Nitrogen |

0.1 |

0.1 |

| Phosphorus |

0.045 |

0.045 |

| Sulfur |

0.03 |

0.03 |

Mechanical Properties

ASTM A240 316 and 316L plates exhibit strong mechanical characteristics suitable for welded structures, pressure vessels, and heavy-duty applications:

| Mechanical Property of 316/316l |

316 |

316L |

| Yield Strength, min. (ksi) |

30 |

25 |

| Tensile Strength, min. (ksi) |

75 |

70 |

| Elongation, min. (%) |

40 |

40 |

| Hardness, max. (Rb) |

95 |

95 |

Stainless Steel Standards of 316/316L steel

| Steel Standards of 316/316L |

| 316 |

316L |

| ASTM A240 |

ASTM A240 |

| ASTM A666 |

ASTM A666 |

| ASME SA240 |

ASME SA240 |

| AMS 5524 |

AMS 5507 |

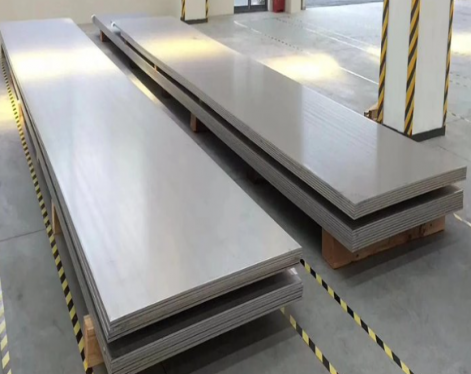

General Properties of 316 Stainless Steel Plate

Alloy 316/316L (UNS S31600/S31603) is a chromium-nickel molybdenum austenitic stainless steel developed to provide improved corrosion resistance to Alloy 304/304L in moderately corrosive environments. It is often utilized in process streams containing chlorides or halides. The addition of molybdenum improves general corrosion and chloride pitting resistance. It also provides higher creep, stress-to-rupture and tensile strength at elevated temperatures.

It is common practice for 316L to be dual certified as 316 and 316L. The low carbon chemistry of 316L combined with an addition of nitrogen enables 316L to meet the mechanical properties of 316.

Alloy 316/316L resists atmospheric corrosion, as well as, moderately oxidizing and reducing environments. It also resists corrosion in polluted marine atmospheres. The alloy has excellent resistance to intergranular corrosion in the as-welded condition. Alloy 316/316L has excellent strength and toughness at cryogenic temperatures.

Alloy 316/316L is non-magnetic in the annealed condition, but can become slightly magnetic as a result of cold working or welding. It can be easily welded and processed by standard shop fabrication practices.

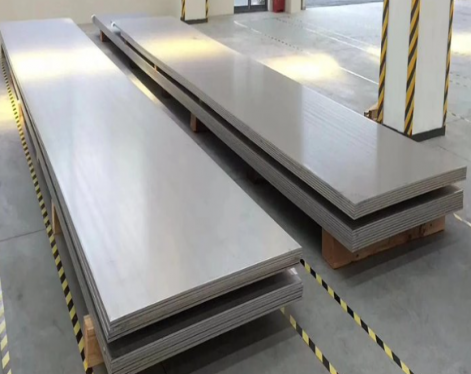

Conclusion

ASTM A240 316/316L stainless steel plate combines exceptional corrosion resistance, strong mechanical performance and flexibility in fabrication, making it a preferred material in demanding engineering and industrial environments. Whether you require high weldability (316L) or enhanced strength at elevated temperatures (316), this grade supports reliable performance for diverse applications.