According to the technical requirements of various international and industry standards, carbon steel plates and their machined parts must be protected against corrosion during storage to prevent degradation of metal properties and even slow crack propagation and potential fracture risks. Common protective methods include coating the product surface with anti-corrosion media such as rust-preventive oil, grease, or varnish to isolate the metal substrate from air and moisture. This requirement is particularly important in fields such as engineering machinery, pressure vessels, and structural components, and is a fundamental prerequisite for ensuring the safe operation of carbon steel plates. Therefore, scientific and standardized storage of carbon steel plates is a key link in ensuring material quality and service life.

Carbon steel plates should be stored in a dry, well-ventilated warehouse. The warehouse floor should be flat and firm, free from standing water and oil stains. The ideal storage environment temperature should be controlled between 5℃ and 40℃, and the relative humidity between 40% and 70%, avoiding extreme temperatures that could affect material properties.

2. Environmental Control

The warehouse should be equipped with dehumidification equipment and a temperature monitoring system to ensure suitable environmental conditions. Humidity should be kept below 60%. A dehumidifier can be used if necessary. Corrosive substances such as acids, alkalis, salts, and cement must not be stored in the warehouse to prevent chemical corrosion and damage to the steel surface.

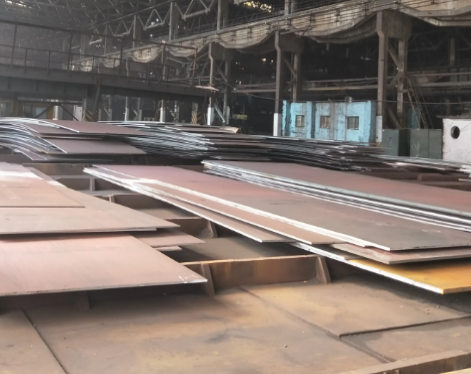

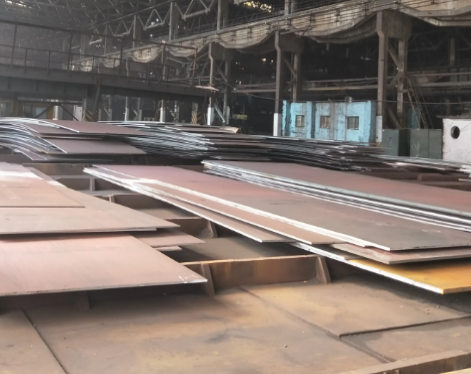

Carbon steel plates should be stacked according to thickness, material, and specifications. Steel of different specifications or materials must be stored separately to avoid confusion and contact corrosion. The "first-in, first-out" principle should be followed, ensuring that materials with longer storage times are used first.

2. Stacking Height

Adjust the stacking height according to the steel plate thickness: thin plates (thickness <10mm) should not exceed 1.5 meters, medium-thick plates (10mm ≤ thickness ≤ 50mm) should not exceed 2 meters, and thick plates (thickness > 50mm) should not exceed 2.5 meters. Rubber pads or thin steel plates should be placed between each layer of steel plates to prevent sticking.

3. Elevation Requirements

Steel plates must be elevated when stacked. The bottom layer should use sleepers or steel pads, at least 200mm off the ground, to prevent direct contact with ground moisture. The spacing between the pads should not exceed 1.5 meters to ensure the bottom layer is stable.

2. For severely corroded steel, it is not advisable to store it for a long time after rust removal; it should be used as soon as possible.

3. Before placing materials in the warehouse, prevent them from being rained on or contaminated with impurities. Materials that have been rained on or contaminated should be cleaned using different methods depending on their properties, such as high-hardness steel wire brushes, low-hardness cloths, cotton cloths, etc.

4. Materials should be inspected frequently after storage. If rust is present, the rust layer should be removed.

Storage Environment Requirements

1. Site SelectionCarbon steel plates should be stored in a dry, well-ventilated warehouse. The warehouse floor should be flat and firm, free from standing water and oil stains. The ideal storage environment temperature should be controlled between 5℃ and 40℃, and the relative humidity between 40% and 70%, avoiding extreme temperatures that could affect material properties.

2. Environmental Control

The warehouse should be equipped with dehumidification equipment and a temperature monitoring system to ensure suitable environmental conditions. Humidity should be kept below 60%. A dehumidifier can be used if necessary. Corrosive substances such as acids, alkalis, salts, and cement must not be stored in the warehouse to prevent chemical corrosion and damage to the steel surface.

Stacking Specifications

1. Stacking PrinciplesCarbon steel plates should be stacked according to thickness, material, and specifications. Steel of different specifications or materials must be stored separately to avoid confusion and contact corrosion. The "first-in, first-out" principle should be followed, ensuring that materials with longer storage times are used first.

2. Stacking Height

Adjust the stacking height according to the steel plate thickness: thin plates (thickness <10mm) should not exceed 1.5 meters, medium-thick plates (10mm ≤ thickness ≤ 50mm) should not exceed 2 meters, and thick plates (thickness > 50mm) should not exceed 2.5 meters. Rubber pads or thin steel plates should be placed between each layer of steel plates to prevent sticking.

3. Elevation Requirements

Steel plates must be elevated when stacked. The bottom layer should use sleepers or steel pads, at least 200mm off the ground, to prevent direct contact with ground moisture. The spacing between the pads should not exceed 1.5 meters to ensure the bottom layer is stable.

Packaging and Protective Material Protective Layers

1. After cleaning the surface of ordinary steel, oiling is not necessary. However, for steel, alloy thin steel plates, thin-walled pipes, alloy steel pipes, etc., both the inner and outer surfaces should be coated with oil after rust removal. Rust-preventive oil must be applied before storage.2. For severely corroded steel, it is not advisable to store it for a long time after rust removal; it should be used as soon as possible.

3. Before placing materials in the warehouse, prevent them from being rained on or contaminated with impurities. Materials that have been rained on or contaminated should be cleaned using different methods depending on their properties, such as high-hardness steel wire brushes, low-hardness cloths, cotton cloths, etc.

4. Materials should be inspected frequently after storage. If rust is present, the rust layer should be removed.