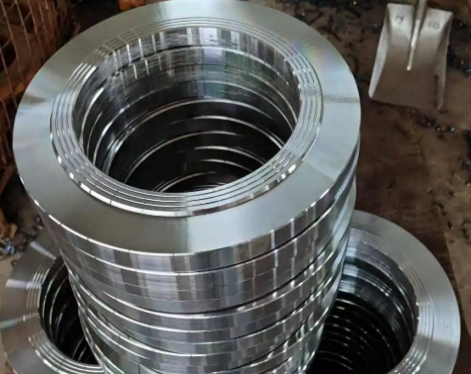

The most significant cosmetic difference between ERW pipe and seamless pipe lies in the weld seam. ERW pipe is made by welding steel strips together, resulting in a distinct longitudinal weld seam on the surface. Seamless pipe, on the other hand, has no weld seams throughout, resulting in a smooth, flowing surface that is more aesthetically pleasing. Therefore, seamless pipe is often preferred in high-end architectural decoration applications such as railings and handrails due to its simple and refined appearance. Next, we will mainly introduce the differences between ERW pipes and seamless pipes from several aspects.

The production process is very different

The difference in appearance is actually closely related to their production process. The differences in the appearance of ERW pipes stem from their manufacturing process. During production, the steel strip is uncoiled, flattened, and rolled into a round tube billet. High-frequency current is then used to heat the edges and squeeze-weld them together, creating a longitudinal weld. Following sizing, flaw detection, and shearing, an ERW pipe is complete.

The production of seamless pipes is more complex. After being heated to high temperatures, steel ingots or solid billets are punched into hollow tubes using a piercing machine. The tubes then undergo hot rolling, cold rolling, or cold drawing to adjust their size and properties. Finally, they undergo sizing, straightening, and flaw detection to produce qualified products.

Performance comparison: Each has its own advantages

In practical applications, ERW pipes and seamless pipes each have their own advantages and disadvantages. In terms of pressure resistance, seamless pipes have a clear advantage in withstanding high pressures due to their seamless structure. For example, in the high-pressure transmission pipelines of the petrochemical industry, seamless pipes can stably transport oil, natural gas and other media to their destinations, ensuring safe and efficient production. Although ERW pipes can withstand a certain amount of pressure, their welds are relatively weak. When the pressure changes suddenly or they are under high pressure for a long time, the welds may crack.

In terms of corrosion resistance, the surface of seamless pipes is smooth and continuous, and there are no weld gaps to accumulate corrosive media. Therefore, in some highly corrosive environments, such as marine engineering, chemical production and other fields, seamless pipes have a longer service life. In desalination plants, seamless pipes effectively resist seawater corrosion and ensure stable equipment operation. However, ERW pipes used in these environments often require special anti-corrosion treatment of the weld seams.

In terms of hardness, the hot-rolled coils used as the raw material for ERW pipes are subjected to extremely high cooling and rolling precision during the rolling process, ensuring uniform performance across all coil sections. Seamless pipes primarily rely on increasing their carbon content to improve their strength, but their balance of strength and ductility is slightly inferior. However, the performance difference between the two is not absolute. With continuous advancements in manufacturing technology, ERW pipes are approaching the performance of seamless pipes.

Different application areas

Due to their performance differences, ERW pipe and seamless pipe have their respective application preferences. ERW pipe, due to its low cost and high production efficiency, is widely used in applications where pressure and environmental requirements are less stringent. For example, in building structures, it is often used as a supporting structure, providing a stable framework. In water and gas pipeline systems, ERW pipe also effectively performs its transportation tasks, meeting daily water and gas supply needs.

Seamless pipes, with their exceptional performance, shine in fields requiring extremely high performance. In the petrochemical industry, chemical reactions often occur under high temperature, high pressure, and in the presence of corrosive media. Seamless pipes can withstand these harsh working conditions and ensure smooth production processes. The aerospace sector places even more stringent demands on material properties. With their high strength, fatigue resistance, and excellent corrosion resistance, seamless pipes are the preferred choice for manufacturing critical components such as aircraft engine parts and fuel lines, providing a solid foundation for safe flight.

Advantages and disadvantages

The pros and cons of seamless pipe:

Seamless pipes are manufactured out of a solid block of steel and do not have any weld seam, which may represent a weak area (subject to corrosion, erosion and, general failure)

Seamless pipes have more predictable and precise shapes, in terms of roundness and ovality, compared to welded pipes.

The main disadvantage of seamless pipes is that their cost per ton is higher than the cost of ERW pipes of the same size and grade (Seamless vs ERW pipe compete in the range 2 to 20 inches)

Delivery times may be longer, as there are fewer manufacturers of seamless pipes than welded pipes (lower entry barriers exists for weldedpipes vs. seamless pipes)

Seamless pipes may have an inconsistent wall thickness across their length, indeed the general tolerance is +/- 12.5%

The pros and cons of ERW pipe:

Welded pipes are cheaper than seamless (ERW HFI type), as they are manufactured using steel coils as feedstock in less complex manufacturing plants.

Welded pipes have shorter lead times than seamless pipes, as the manufacturing base is larger.

Welded pipes have a consistent wall thickness, as they are manufactured using coils (ERW) or plates (LSAW), both subject to tight tolerance control.

The major "defect" attributed to welded pipes is that the presence of a weld seam constitutes a weakness factor. Whereas this may have been true in the past, this is becoming less and less true with the advances of the welding technologies in the last ten years.

Read more: ERW Pipe VS SAW Pipe

The production process is very different

The difference in appearance is actually closely related to their production process. The differences in the appearance of ERW pipes stem from their manufacturing process. During production, the steel strip is uncoiled, flattened, and rolled into a round tube billet. High-frequency current is then used to heat the edges and squeeze-weld them together, creating a longitudinal weld. Following sizing, flaw detection, and shearing, an ERW pipe is complete.

The production of seamless pipes is more complex. After being heated to high temperatures, steel ingots or solid billets are punched into hollow tubes using a piercing machine. The tubes then undergo hot rolling, cold rolling, or cold drawing to adjust their size and properties. Finally, they undergo sizing, straightening, and flaw detection to produce qualified products.

Performance comparison: Each has its own advantages

In practical applications, ERW pipes and seamless pipes each have their own advantages and disadvantages. In terms of pressure resistance, seamless pipes have a clear advantage in withstanding high pressures due to their seamless structure. For example, in the high-pressure transmission pipelines of the petrochemical industry, seamless pipes can stably transport oil, natural gas and other media to their destinations, ensuring safe and efficient production. Although ERW pipes can withstand a certain amount of pressure, their welds are relatively weak. When the pressure changes suddenly or they are under high pressure for a long time, the welds may crack.

In terms of corrosion resistance, the surface of seamless pipes is smooth and continuous, and there are no weld gaps to accumulate corrosive media. Therefore, in some highly corrosive environments, such as marine engineering, chemical production and other fields, seamless pipes have a longer service life. In desalination plants, seamless pipes effectively resist seawater corrosion and ensure stable equipment operation. However, ERW pipes used in these environments often require special anti-corrosion treatment of the weld seams.

In terms of hardness, the hot-rolled coils used as the raw material for ERW pipes are subjected to extremely high cooling and rolling precision during the rolling process, ensuring uniform performance across all coil sections. Seamless pipes primarily rely on increasing their carbon content to improve their strength, but their balance of strength and ductility is slightly inferior. However, the performance difference between the two is not absolute. With continuous advancements in manufacturing technology, ERW pipes are approaching the performance of seamless pipes.

Different application areas

Due to their performance differences, ERW pipe and seamless pipe have their respective application preferences. ERW pipe, due to its low cost and high production efficiency, is widely used in applications where pressure and environmental requirements are less stringent. For example, in building structures, it is often used as a supporting structure, providing a stable framework. In water and gas pipeline systems, ERW pipe also effectively performs its transportation tasks, meeting daily water and gas supply needs.

Seamless pipes, with their exceptional performance, shine in fields requiring extremely high performance. In the petrochemical industry, chemical reactions often occur under high temperature, high pressure, and in the presence of corrosive media. Seamless pipes can withstand these harsh working conditions and ensure smooth production processes. The aerospace sector places even more stringent demands on material properties. With their high strength, fatigue resistance, and excellent corrosion resistance, seamless pipes are the preferred choice for manufacturing critical components such as aircraft engine parts and fuel lines, providing a solid foundation for safe flight.

Advantages and disadvantages

The pros and cons of seamless pipe:

Seamless pipes are manufactured out of a solid block of steel and do not have any weld seam, which may represent a weak area (subject to corrosion, erosion and, general failure)

Seamless pipes have more predictable and precise shapes, in terms of roundness and ovality, compared to welded pipes.

The main disadvantage of seamless pipes is that their cost per ton is higher than the cost of ERW pipes of the same size and grade (Seamless vs ERW pipe compete in the range 2 to 20 inches)

Delivery times may be longer, as there are fewer manufacturers of seamless pipes than welded pipes (lower entry barriers exists for weldedpipes vs. seamless pipes)

Seamless pipes may have an inconsistent wall thickness across their length, indeed the general tolerance is +/- 12.5%

The pros and cons of ERW pipe:

Welded pipes are cheaper than seamless (ERW HFI type), as they are manufactured using steel coils as feedstock in less complex manufacturing plants.

Welded pipes have shorter lead times than seamless pipes, as the manufacturing base is larger.

Welded pipes have a consistent wall thickness, as they are manufactured using coils (ERW) or plates (LSAW), both subject to tight tolerance control.

The major "defect" attributed to welded pipes is that the presence of a weld seam constitutes a weakness factor. Whereas this may have been true in the past, this is becoming less and less true with the advances of the welding technologies in the last ten years.

Read more: ERW Pipe VS SAW Pipe