Carbon Steel Pipe

Stainless Steel Pipe

Fittings

OCTG

Steel Structure

Value-Added Products

Clad Pipe

Coated Steel Pipe

Technical Data

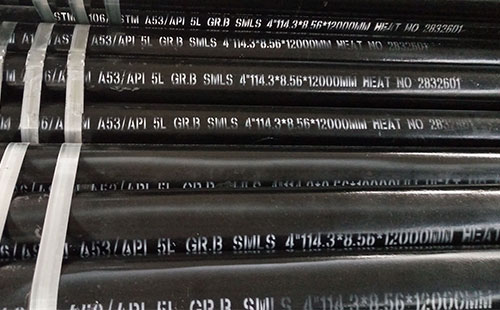

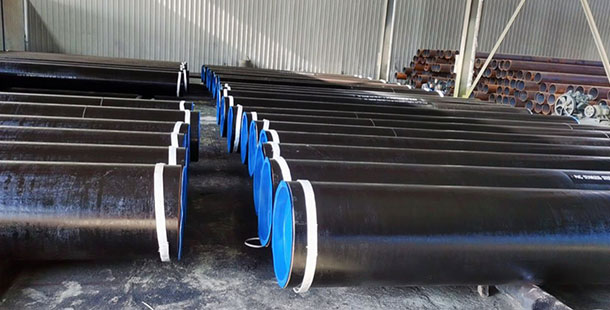

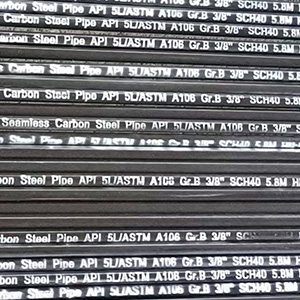

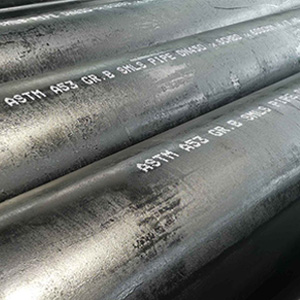

Photos

- Seamless steel pipes are derived from solid steel that is in sheet or bar form and is formed into a solid round shape known as “billets” which are then heated and cast over a form such as a piercing rod to create a hollow tube or shell.The abbreviation of seamless steel pipe is smls pipe.

Standards of seamless steel pipe

| API SPEC 5L | |||

| Product Name | Executive Standard | Dimension (mm) | Steel Code / Steel Grade |

| Line Pipes | API 5L | Ø10.3~1200 x WT1.0~120 | A, B, X42, X46, X52, X60, X70, X80, PSL1 / PSL2 |

| API SPEC 5CT | |||

| Product Name | Executive Standard | Dimension (mm) | Steel Code / Steel Grade |

| Casing | API 5CT | Ø114~219 x WT5.2~22.2 | J55, K55, N80, L80, P110 |

| Tubing | API 5CT | Ø48.3~114.3 x WT3.2~16 | J55, K55, N80, L80, P110 |

| ASTM / ASME | |||

| Product Name | Executive Standard | Dimension (mm) | Steel Code / Steel Grade |

| Black and Hot-Dipped Zinc-Coated Seamless Steel Pipes | ASTM A53 | Ø10.3~1200 x WT1.0~150 | Gr.A, Gr.B, Gr.C |

| Seamless Carbon Steel Pipes for High Temperature Service | ASTM A106 | Ø10.3~1200 x WT1.0~150 | Gr.B, Gr.C |

| Seamless Cold-Drawn Low-Carbon Steel Heat-Exchanger and Condenser Tubes | ASTM A179 | Ø10.3~426 x WT1.0~36 | Low Carbon Steel |

| Seamless Carbon Steel Boiler Tubes for High Pressure | ASTM A192 | Ø10.3~426 x WT1.0~36 | Low Carbon Steel |

| Seamless Cold-Drawn Intermediate Alloy Steel Heat-Exchanger and Condenser Tubes | ASTM A199 | Ø10.3~426 x 1.0~36 | T5, T22 |

| Seamless Medium-Carbon Steel Boiler and Superheater Tubes | ASTM A210 | Ø10.3~426 x WT1.0~36 | A1, C |

| Seamless Ferritic & Austenitic Alloy Steel Boiler, Superheater & Heat-Exchanger Tubes | ASTM A213 | Ø10.3~426 x WT1.0~36 | T5, T9, T11, T12, T22, T91 |

| Seamless Carbon and Alloy Steel for Mechanical Tubing | ASTM A333 | Ø1/4"~42" x WT SCH20~XXS | Gr.1, Gr.3, Gr.6 |

| Seamless & Welded Carbon Steel Pipes and Alloy Steel Pipes for Low Temperature Use | ASTM A334 | Ø1/4"~4" x WT SCH20~SCH80 | Gr.1, Gr.6 |

| Seamless Cold-Drawn Carbon Steel Feedwater Heater Tubes | ASTM A556 | Ø10.3~426 x WT1.0~36 | A2, B2 |

| DIN | |||

| Product Name | Executive Standard | Dimension (mm) | Steel Code / Steel Grade |

| Seamless Steel Tubes for Elevated Temperature | DIN 17175 | Ø10~762 x WT1.0~120 | St35.8, St45.8, 10CrMo910, 15Mo3, 13CrMo44, STPL340, STB410, STB510, WB36 |

| Seamless Steel Tubes | DIN 1629 / DIN 2391 | Ø13.5~762 x WT1.8~120 | St37.0, St44.0, St52.0, St52.3 |

| Seamless Steel Tubes | DIN 2440 | Ø13.5~165.1 x WT1.8~4.85 | St33.2 |

| Seamless Steel Pipes for Structural Purpose | DIN 2393 | Ø16~426 x WT1.0~36 | RSt34-2, RSt37-2, RSt44-2, St52 |

| BS | |||

| Product Name | Executive Standard | Dimension (mm) | Steel Code / Steel Grade |

| Seamless Steel Tubes for Machine Structure | BS 970 | Ø10~762 x WT1.0~120 | Carbon Steel |

| Seamless Steel Tubes for Boiler and Heat Exchangers | BS 3059 | Ø10~762 x WT1.0~120 | 360, 410, 440, 460, 490 |

Specification of seamless steel pipe

Out diameter: 1/2 inch - 36 inch (21.3mm-914.4mm)

Thickness: 2.11mm-60mm ( SCH10, SCH20, SCH40, SCH80, STD, SCH120, SCH160, XXS)

| NOMINAL PIPE SIZE | OD(mm) | NOMINAL WALL THICKNESS | |||||||||||||

| DN | NB(inch) | ASME | SCH10 | SCH20 | SCH30 | STD | SCH40 | SCH60 | XS | SCH80 | SCH100 | SCH120 | SCH140 | SCH160 | XXS |

| 15 | 1/2" | 21.3 |

2.11 | 2.41 | 2.77 | 2.77 | 3.73 | 3.73 | 4.78 | 7.47 | |||||

| 20 | 3/4" | 26.7 | 2.11 | 2.41 | 2.87 | 2.87 | 3.91 | 3.91 | 5.56 | 7.82 | |||||

| 25 | 1" | 33.4 | 2.77 | 2.9 | 3.38 | 3.38 | 4.55 | 4.55 | 6.35 | 9.09 | |||||

| 32 | 1.1/4" | 42.2 | 2.77 | 2.97 | 3.56 | 3.56 | 4.85 | 4.85 | 6.35 | 9.7 | |||||

| 40 | 1.1/2" | 48.3 | 2.77 | 3.18 | 3.68 | 3.68 | 5.08 | 5.08 | 7.14 | 10.15 | |||||

| 50 | 2" | 60.3 | 2.77 | 3.18 | 3.91 | 3.91 | 5.54 | 5.54 | 8.74 | 11.07 | |||||

| 65 | 2.1/2" | 73 | 3.05 | 4.78 | 5.16 | 5.16 | 7.01 | 7.01 | 9.53 | 14.02 | |||||

| 80 | 3" | 88.9 | 3.05 | 4.78 | 5.49 | 5.49 | 7.62 | 7.62 | 11.13 | 15.25 | |||||

| 90 | 3.1/2" | 101.6 | 3.05 | 4.78 | 5.74 | 5.74 | 8.08 | 8.08 | |||||||

| 100 | 4" | 114.3 | 3.05 | 4.78 | 6.02 | 6.02 | 8.56 | 8.56 | 11.13 | 13.49 | 17.12 | ||||

| 125 | 5" | 141.3 | 3.4 | 6.55 | 6.55 | 9.53 | 9.53 | 12.7 | 15.88 | 19.05 | |||||

| 150 | 6" | 168.3 | 3.4 | 7.11 | 7.11 | 10.97 | 10.97 | 14.27 | 18.26 | 21.95 | |||||

| 200 | 8" | 219.1 | 3.76 | 6.35 | 7.04 | 8.18 | 8.18 | 10.31 | 12.7 | 12.7 | 15.09 | 18.26 | 20.62 | 23.01 | 22.23 |

| 250 | 10" | 273 | 4.19 | 6.35 | 7.8 | 9.27 | 9.27 | 12.7 | 12.7 | 15.09 | 18.26 | 21.44 | 25.4 | 28.58 | 25.4 |

| 300 | 12" | 323.8 | 4.57 | 6.35 | 8.38 | 9.53 | 10.31 | 14.27 | 12.7 | 17.48 | 21.44 | 25.4 | 28.58 | 33.32 | 25.4 |

| 350 | 14" | 355.6 | 6.35 | 7.92 | 9.53 | 9.53 | 11.13 | 15.09 | 12.7 | 19.05 | 23.83 | 27.79 | 31.75 | 35.71 | |

| 400 | 16" | 406.4 | 6.35 | 7.92 | 9.53 | 9.53 | 12.7 | 16.66 | 12.7 | 21.44 | 26.19 | 30.96 | 36.53 | 40.19 | |

| 450 | 18" | 457.2 | 6.35 | 7.92 | 11.13 | 9.53 | 14.27 | 19.05 | 12.7 | 23.83 | 39.36 | 34.93 | 39.67 | 45.24 | |

| 500 | 20" | 508 | 6.35 | 9.53 | 12.7 | 9.53 | 15.09 | 20.62 | 12.7 | 26.19 | 32.54 | 38.1 | 44.45 | 50.01 | |

| 550 | 22" | 558.8 | 6.35 | 9.53 | 12.7 | 9.53 | 22.23 | 12.7 | 28.58 | 34.93 | 41.28 | 47.63 | 53.98 | ||

| 600 | 24" | 609.6 | 6.35 | 9.53 | 14.27 | 9.53 | 17.48 | 24.61 | 12.7 | 30.96 | 38.89 | 46.02 | 52.37 | 59.54 | |

| 650 | 26" | 660.4 | 7.92 | 12.7 | 9.53 | 12.7 | |||||||||

| 700 | 28" | 711.2 | 7.92 | 12.7 | 15.88 | 9.53 | 12.7 | ||||||||

| 750 | 30" | 762 | 7.92 | 12.7 | 15.88 | 9.53 | 12.7 | ||||||||

| 800 | 32" | 812.8 | 7.92 | 12.7 | 15.88 | 9.53 | 17.48 | 12.7 | |||||||

| 850 | 34" | 863.6 | 7.92 | 12.7 | 15.88 | 9.53 | 17.48 | 12.7 | |||||||

| 900 | 36" | 914.4 | 7.92 | 12.7 | 15.88 | 9.53 | 19.05 | 12.7 | |||||||

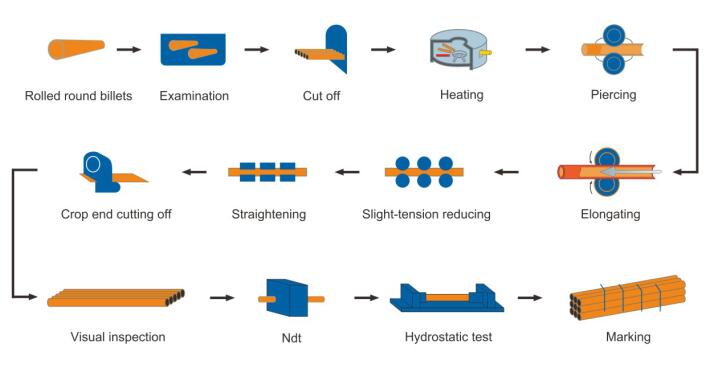

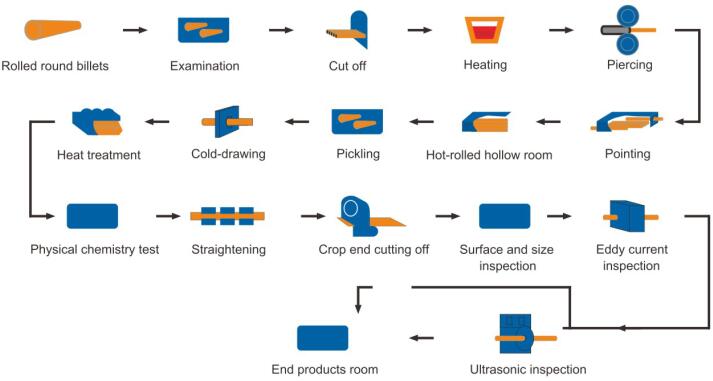

Process of seamless steel pipe

According to different manufacturing(mfg), seamless steel pipe can be divided into hot rolled pipe, cold rolled pipe, cold drawn pipe and extruded pipe.

Hot Rolled Process for Seamless Steel Pipe

Round Pipe Billet → Heating → Punching → Three-Roller Skew Rolling, Continuous Rolling or Extruding → Pipe Detaching →

Micro Tension Sizing or Reducing → Cooling → Straightening → Hydrostatic Test or Inspection → Marking → Warehousing

Cold Drawn Process for Seamless Steel Pipe

Round Pipe Billet → Heating → Punching → Pipe Head Treatment → Annealing → Acid Pickling → Coating Oil → Multi-pass Cold Drawing

→ Pipe Billet→ Heat Treatment → Straightening →Hydrostatic Test or Inspection → Marking → Warehousing

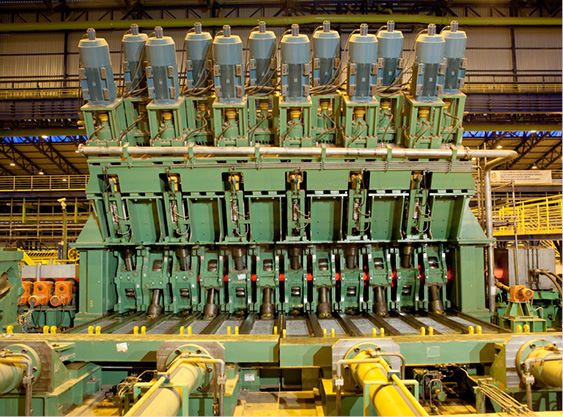

Production equipments of all process

| Starting material Steel billets of various dimensions and grades, continuously cast or rolled Billet preparation Billet saws Furnace technology Billet centering  |

Piercing From the billet to the hollow Cross-rolling mills (cone type and barrel type piercing) Billet descaling 3-roll piercing mills Hollow inside deoxidation Cooling and quick-change systems for piercing tools  |

Elongating expanding From the hollow to the shell PQF® / MPM mill CPE/TPE mill / Push bench technology Assel mills, Plug mills, Hot pilger mills Elongators Rotary Expanders  |

| Finish rolling From the shell to the tube Reheating furnace (gas fired/induction) High pressure water descaling unit Sizing mill, Stretch-reducing mill FPS adjustable rolling stands Tube layer saws  |

Finishing line From the rolling mill to the dispatch area Groove dressing machines for PQF® cartridges Stretch-reducing and sizing mill stands  |

Products Seamless tubes of various dimensions Diameters: 21.3 mm to 914.4 mm Wall thicknesses: 2.11 mm to 60 mm  |

| NOMINAL PIPE SIZE | OD(mm) | NOMINAL WALL THICKNESS | |||||||||||||

| DN | NB(inch) | ASME | SCH10 | SCH20 | SCH30 | STD | SCH40 | SCH60 | XS | SCH80 | SCH100 | SCH120 | SCH140 | SCH160 | XXS |

| 15 | 1/2" | 21.3 |

2.11 | 2.41 | 2.77 | 2.77 | 3.73 | 3.73 | 4.78 | 7.47 | |||||

| 20 | 3/4" | 26.7 | 2.11 | 2.41 | 2.87 | 2.87 | 3.91 | 3.91 | 5.56 | 7.82 | |||||

| 25 | 1" | 33.4 | 2.77 | 2.9 | 3.38 | 3.38 | 4.55 | 4.55 | 6.35 | 9.09 | |||||

| 32 | 1.1/4" | 42.2 | 2.77 | 2.97 | 3.56 | 3.56 | 4.85 | 4.85 | 6.35 | 9.7 | |||||

| 40 | 1.1/2" | 48.3 | 2.77 | 3.18 | 3.68 | 3.68 | 5.08 | 5.08 | 7.14 | 10.15 | |||||

| 50 | 2" | 60.3 | 2.77 | 3.18 | 3.91 | 3.91 | 5.54 | 5.54 | 8.74 | 11.07 | |||||

| 65 | 2.1/2" | 73 | 3.05 | 4.78 | 5.16 | 5.16 | 7.01 | 7.01 | 9.53 | 14.02 | |||||

| 80 | 3" | 88.9 | 3.05 | 4.78 | 5.49 | 5.49 | 7.62 | 7.62 | 11.13 | 15.25 | |||||

| 90 | 3.1/2" | 101.6 | 3.05 | 4.78 | 5.74 | 5.74 | 8.08 | 8.08 | |||||||

| 100 | 4" | 114.3 | 3.05 | 4.78 | 6.02 | 6.02 | 8.56 | 8.56 | 11.13 | 13.49 | 17.12 | ||||

| 125 | 5" | 141.3 | 3.4 | 6.55 | 6.55 | 9.53 | 9.53 | 12.7 | 15.88 | 19.05 | |||||

| 150 | 6" | 168.3 | 3.4 | 7.11 | 7.11 | 10.97 | 10.97 | 14.27 | 18.26 | 21.95 | |||||

| 200 | 8" | 219.1 | 3.76 | 6.35 | 7.04 | 8.18 | 8.18 | 10.31 | 12.7 | 12.7 | 15.09 | 18.26 | 20.62 | 23.01 | 22.23 |

| 250 | 10" | 273 | 4.19 | 6.35 | 7.8 | 9.27 | 9.27 | 12.7 | 12.7 | 15.09 | 18.26 | 21.44 | 25.4 | 28.58 | 25.4 |

| 300 | 12" | 323.8 | 4.57 | 6.35 | 8.38 | 9.53 | 10.31 | 14.27 | 12.7 | 17.48 | 21.44 | 25.4 | 28.58 | 33.32 | 25.4 |

| 350 | 14" | 355.6 | 6.35 | 7.92 | 9.53 | 9.53 | 11.13 | 15.09 | 12.7 | 19.05 | 23.83 | 27.79 | 31.75 | 35.71 | |

| 400 | 16" | 406.4 | 6.35 | 7.92 | 9.53 | 9.53 | 12.7 | 16.66 | 12.7 | 21.44 | 26.19 | 30.96 | 36.53 | 40.19 | |

| 450 | 18" | 457.2 | 6.35 | 7.92 | 11.13 | 9.53 | 14.27 | 19.05 | 12.7 | 23.83 | 39.36 | 34.93 | 39.67 | 45.24 | |

| 500 | 20" | 508 | 6.35 | 9.53 | 12.7 | 9.53 | 15.09 | 20.62 | 12.7 | 26.19 | 32.54 | 38.1 | 44.45 | 50.01 | |

| 550 | 22" | 558.8 | 6.35 | 9.53 | 12.7 | 9.53 | 22.23 | 12.7 | 28.58 | 34.93 | 41.28 | 47.63 | 53.98 | ||

| 600 | 24" | 609.6 | 6.35 | 9.53 | 14.27 | 9.53 | 17.48 | 24.61 | 12.7 | 30.96 | 38.89 | 46.02 | 52.37 | 59.54 | |

| 650 | 26" | 660.4 | 7.92 | 12.7 | 9.53 | 12.7 | |||||||||

| 700 | 28" | 711.2 | 7.92 | 12.7 | 15.88 | 9.53 | 12.7 | ||||||||

| 750 | 30" | 762 | 7.92 | 12.7 | 15.88 | 9.53 | 12.7 | ||||||||

| 800 | 32" | 812.8 | 7.92 | 12.7 | 15.88 | 9.53 | 17.48 | 12.7 | |||||||

| 850 | 34" | 863.6 | 7.92 | 12.7 | 15.88 | 9.53 | 17.48 | 12.7 | |||||||

| 900 | 36" | 914.4 | 7.92 | 12.7 | 15.88 | 9.53 | 19.05 | 12.7 | |||||||

- United Arab Emirates

Pipe, Generic: Size 24 in, SCH STD,Material A106 carbon steel, Grade B,

Specification B16-25 THK B36, Bevelled Ends, Seamless Type

Saudi Arabia

14” Seamless pipe with 1” wall thickness, ASTM A53 GR.B

Chile

API 5L-Gr-B size 323.85 mm x10.31 mm x 12 meters Long PE

Brazil

3/8" PIPE ASME B36.10 BE SCH 40 SEAMLESS ASTM A106 GR.B – 6 meters

Nigeria

MATERIAL:Seamless Steel Tubes. GRADE:A106 Gr B.

SIZES:1) 60.32mm OD X +/- 5.54mm WT

2) 168.3mm OD X +/- 7.11mm WT

Morocco

Seamless Steel Pipe API 5L Grade B sch 40 with 3PE Coated pipe in polyethylene

- 400 m; size 8'' inch (DN200) ;OD=219,08mm ; WT=8,18mm ; Length=5,8M

- 100 m; size 4'' inch (DN100) ;OD=114,3mm ; WT=6,02mm ; Length=5,8M

Malaysia

Standard weight seamless steel pipes to ASTM -A53 Grade A Schedule 40.

1. 150mm seamless pipes = 1792m

2. 200mm seamless pipes = 11531m

3. 250mm Seamless pipes = 9240m

Singapore

Pipe Carbon Steel API 5L Seamless Pipe, Schedule– 40, Size– 500mm, Length– 6m each