Carbon Steel Pipe

Stainless Steel Pipe

Fittings

OCTG

Steel Structure

Value-Added Products

Clad Pipe

Coated Steel Pipe

Technical Data

Photos

- There are many different types of valves available, each suited to a particular purpose. Valves are made from a wide variety of materials and found in virtually every industrial process.

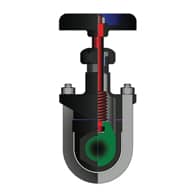

Ball Valves are a form of quarter-turn valves which use a hollow ball that pivots to control flow through it. The handle aligns with the flow when open, is perpendicular to it when closed, making for easy visual confirmation of the valve's status. Ball Valves are durable and reliable, closing securely even after long periods of disuse, making them a popular choice for shutoff and control applications.

Ball Valves are stocked in sizes from 1/4" to 6".

Available in a variety of materials including brass, carbon steel, and stainless steel.

All Ball Valves listed here have a teflon seat.

Both Reduced-Port and Full-Port Ball Valves are stocked.

Both flanged and threaded ball valves are available.

Threaded & Socket Weld Ball Valves---Ball Valves ¼”- 4” One, Two & Three Piece

Flanged Ball Valves---1/2” – 10” Flanged One Piece & Two Piece

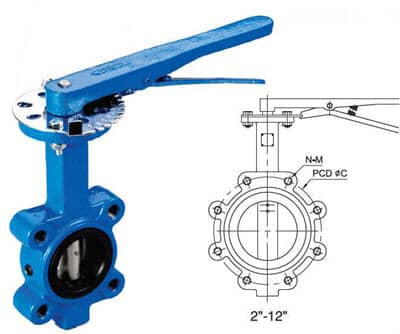

Butterfly Valve is a form of a quarter-turn valve which uses a metal disk for the closing mechanism. The disk is positioned in the center of the pipe and is open when the surface of the disc is parallel to the flow, closed when the disc is perpendicular to the flow. All of the Butterfly Valves we stock are designed to be connected between two flanges.

Lug type Butterfly Valves connect between two flanges and have threaded inserts so that each flange can be bolted to the valve.

Wafer type Butterfly Valves are sandwiched between two flanges, but the valve is not bolted to either flange.

Butterfly Valves are stocked in sizes from 2 to 12 inches.

All have a BUNA seat and Nickel plated disc..

High Performance Double Offset Butterfly Valves

Resilient Seated Butterfly Valves

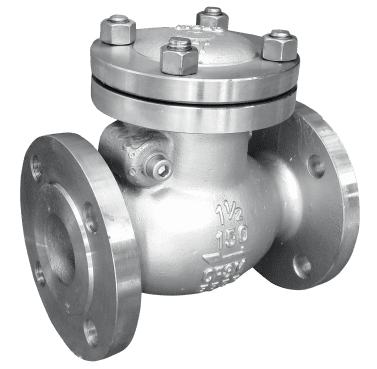

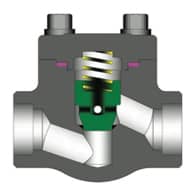

Check Valve is a device that allows liquid or gas to flow through it in only one direction. Check Valves generally work automatically and have no external controls. Other names for Check Valves are clack valves, one-way valves, and non-return valves.

Check Valves are stocked in sizes from 1/2" to 4".

Available in a variety of materials including brass, bronze and cast steel.

We carry both threaded and flanged end Check Valves.

Both Horizontal-Swing and Inline-Spring-Loaded Check Valves are stocked.

MSS SP-80 Bronze Check Valves----ASME Class 125 - 300 Ranging from 1/4" - 3"

Iron Check Valves---ASME Class 125 Ranging from 2" - 24"

API 600 Cast Steel Check Valves---ASME Class 150 - 1500 Ranging from 2" - 24"

API 602 Forged Steel Check Valves---ASME Class 150 - 2680 Ranging from 1/4" - 2"

API 603 Corrosion Resistant Check Valves---ASME Class 150 - 600 Ranging from 1/4" - 24"

API 600 Pressure Seal Check Valves---ASME Class 600 - 2500 Ranging from 2" - 24"

Stainless Steel Cryogenic Check Valves---ASME Class 150 - 600 Ranging from 1/4" - 12"

Bronze Cryogenic Check Valves---ASME Class 125 - 300 Ranging from 1/4" - 3"

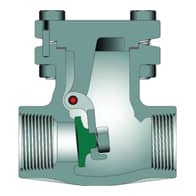

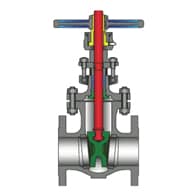

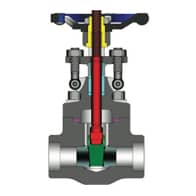

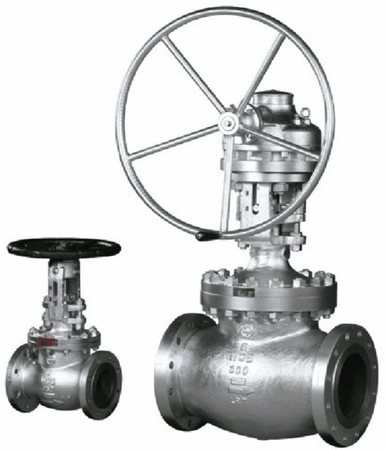

Gate Valves open by lifting a round or rectangular gate out of the path of the fluid. Generally, Gate Valves are used with liquids and are designed to be either fully opened or closed. When fully open, the typical gate valve has no obstruction in the flow path, resulting in lower friction loss than other types of valves.

Gate Valves are also known as sluice valves.

Rising Stem Gate Valves provide a visual indication for the valve status.

Gate Valves are stocked in sizes from 1/2" to 6".

Available in a variety of materials including brass, bronze and cast steel and forged steel.

We carry Threaded, Socket Weld and Flanged End Gate Valves.

Bronze Gate Valves

ASME Class 125 - 300 Ranging from 1/4" - 12"

Iron Gate Valves---ASME Class 125 - 250 Ranging from 1/4" - 24"

API 600 Cast Steel Gate Valves---ASME Class 150 - 1500 Ranging from 1" - 42"

API 602 Forged Steel Gate Valves---ASME Class 150 - 2680 Ranging from 1/4" - 2"

API 603 Corrosion Resistant Gate Valves---ASME Class 150 - 600 Ranging from 1/4" - 24"

API 600 Pressure Seal Gate Valves---ASME Class 600 - 2500 Ranging from 2" - 24"

Stainless Steel Cryogenic Gate Valves---ASME Class 150 - 600 Ranging from 1/4" - 12"

Bronze Cyrogenic Gate Valves--ASME Class 125 - 300 Ranging from 1/4" - 12"

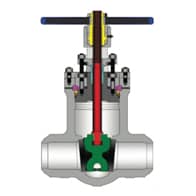

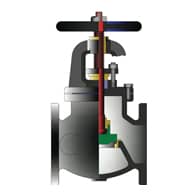

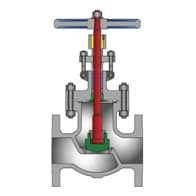

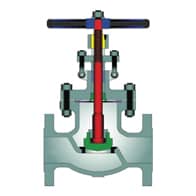

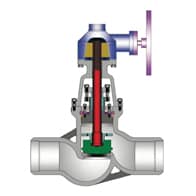

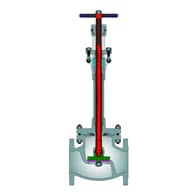

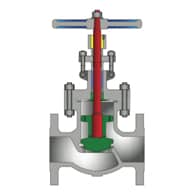

Globe Valve

Body Construction: T-type,Y-type,Angel type.

Bonnet Design: Bolted bonnet, Welded bonnet, Pressure sealed bonnet

Design and Manufacture: API 602,BS 5352,ASME B16.34/B16.11/B1.20.1/B16.25 /B16.5

Size Range: 1/2"~4"

Pressure Ratings: 150LB-2500LB

Temperature Range: -196℃~500℃

End Connections: Threaded,Socket-Welded,Butt-Welded,Flange Type(Welded flange &Integral flange)

Face to Face Dimension: ASME B16.10 and other standard

Inspection and Testing: API 598 and other standard

Bronze Globe Valves---ASME Class 125 - 300 Ranging from 1/4" - 3"

Iron Globe Valves---ASME Class 125 Ranging from 2" - 12"

API 600 Cast Steel Globe Valves---ASME Class 150 - 1500 Ranging from 2" - 24"

API 602 Forged Steel Globe Valves---ASME Class 150 - 2680 Ranging from 1/4" - 2"

API 603 Corrosion Resistant Globe Valves---ASME Class 150 - 600 Ranging from 1/4" - 12"

API 600 Pressure Seal Globe Valves---ASME Class 600 - 2500 Ranging from 2" - 24"

Stainless Steel Cryogenic Globe Valves---ASME Class 150 - 600 Ranging from 1/4" - 12"

Bronze Cyrogenic Globe Valves---ASME Class 125 - 300 Ranging from 1/4" - 3"

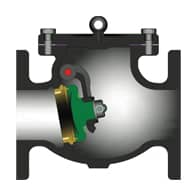

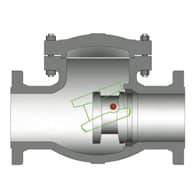

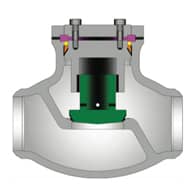

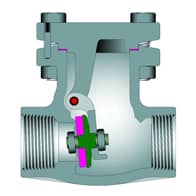

Non-Return Valves

Non-returnable valves received their name from what they do. These values allow fluid, whether in the form of liquid or gas, to flow in only one direction. These one-way valves only restrict the flow in one direction, while allowing full and unimpeded flow in the opposite direction.There are different types of non-return valves such as: spring-loaded, clapper and swing type. These specific valves are used mainly in heating and cooling systems but can also be seen in water systems and boilers.

ASME Class 300 - 600 Ranging from 4" - 12"

2" to 12" Non-Return Valve Class 600 - 2500

2" to 12" Non-Return Valve (Y-Pattern) Class 600 - 2500

- Class 150

Dimensions and Weights (*Gear Operated )

| Nom Size | Face to Face RF | Face to Face RTJ | Face to Face BW | Height.. | Handwheel Diameter..Weight.. | Weight | ||||

| in | in | mm | in | mm | in | mm | in | mm | mm | Kgs |

| 2 | 7 | 178 | 7.52 | 191 | 8.5 | 216 | 16.1 | 409 | 200 | 18 |

| 21.2 | 7.5 | 190 | 8 | 203 | 9.5 | 241 | 17.4 | 442 | 200 | 28 |

| 3 | 8 | 203 | 8.5 | 216 | 11.1 | 283 | 20 | 508 | 250 | 34 |

| 4 | 9 | 229 | 9.5 | 241 | 12 | 305 | 23.2 | 590 | 250 | 52 |

| 5 | 10 | 254 | 10.5 | 267 | 15 | 381 | 26.5 | 673 | 250 | 71 |

| 6 | 10.5 | 267 | 11 | 279 | 15.8 | 403 | 30.2 | 767 | 300 | 88 |

| 8 | 11.5 | 292 | 12 | 305 | 16.5 | 419 | 37.8 | 960 | 350 | 144 |

| 10 | 13 | 330 | 13.5 | 343 | 18 | 457 | 45.6 | 1158 | 400 | 197 |

| 12 | 14 | 356 | 14.5 | 368 | 19.8 | 502 | 54.3 | 1378 | 450 | 298 |

| 14 | 15 | 381 | 15.5 | 394 | 22.5 | 572 | 60.75 | 1543 | 500 | 406 |

| 16 | 16 | 406 | 16.5 | 419 | 24 | 610 | 68.4 | 1738 | 600 | 524 |

| 18 | 17 | 432 | 17.5 | 445 | 26 | 660 | 77.1 | 1959 | 600 | 720 |

| 20 | 18 | 457 | 18.5 | 470 | 28 | 711 | 87.2 | 2214 | 680 | 1117 |

| 24 | 20 | 508 | 20.5 | 521 | 32 | 813 | 102.3 | 2599 | 760 | 1466 |

| 26* | 22 | 559 | 22.5 | 572 | 34 | 863 | 121.5 | 3086 | GO | 1699 |

| 28* | 24 | 610 | 24.5 | 622 | 36 | 914 | 131 | 3327 | GO | 1931 |

| 30* | 24 | 610 | 24.5 | 622 | 36 | 914 | 142 | 3606 | GO | 2380 |

| 32* | 26 | 660 | 26.5 | 673 | 38 | 965 | 146 | 3708 | GO | 2490 |

| 36* | 28 | 711 | 28.5 | 724 | 40 | 1016 | 154.5 | 3924 | GO | 3600 |

| 42* | 32 | 813 | 32.5 | 826 | 45 | 1143 | 179 | 4546 | GO | 4710 |

| 48* | 42 | 1066 | 42.5 | 1079 | 54 | 1371 | 204 | 5181 | GO | 6500 |

Class 300

Dimensions and Weights (*Gear Operated )

| Nom Size | Face to Face RF | Face to Face RTJ | Face to Face BW | Height.. | Handwheel Diameter..Weight.. | Weight | ||||

| in | in | mm | in | mm | in | mm | in | mm | mm | Kgs |

| 2 | 8.5 | 216 | 9.12 | 232 | 8.5 | 216 | 16.7 | 424 | 200 | 24 |

| 21.2 | 9.5 | 241 | 10.12 | 257 | 9.5 | 241 | 18.1 | 460 | 200 | 44 |

| 3 | 11.13 | 283 | 11.8 | 298 | 11.13 | 283 | 21 | 535 | 250 | 52 |

| 4 | 12 | 305 | 12.6 | 321 | 2 | 305 | 24.2 | 615 | 250 | 76 |

| 5 | 15 | 381 | 15.6 | 397 | 15 | 381 | 26.1 | 662 | 350 | 94 |

| 6 | 15.86 | 403 | 16.5 | 419 | 15.86 | 403 | 31.3 | 795 | 350 | 146 |

| 8 | 16.5 | 419 | 17.1 | 435 | 16.5 | 419 | 39.9 | 1012 | 400 | 218 |

| 10 | 18 | 457 | 18.6 | 473 | 18 | 457 | 48.5 | 1231 | 450 | 352 |

| 12 | 19.75 | 502 | 20.4 | 518 | 19.75 | 502 | 57 | 1450 | 500 | 472 |

| 14 | 30 | 762 | 30.6 | 778 | 30 | 762 | 64.8 | 1645 | 600 | 694 |

| 16 | 33 | 838 | 33.6 | 854 | 33 | 838 | 72.5 | 1841 | 600 | 1080 |

| 18 | 36 | 914 | 36.6 | 930 | 36 | 914 | 76.5 | 1943 | 680 | 1235 |

| 20 | 39 | 991 | 39.8 | 1010 | 39 | 991 | 84.8 | 2154 | 965 | 1655 |

| 24 | 45 | 1143 | 45.9 | 1165 | 45 | 1143 | 100.5 | 2553 | 915 | 2320 |

| 26* | 49 | 1244 | 49.8 | 1266 | 49 | 1244 | 108.3 | 2750 | GO | 3100 |

| 28* | 53 | 1346 | 53.9 | 1368 | 53 | 1346 | 122.05 | 3100 | GO | 3893 |

| 30* | 55 | 1397 | 56 | 1422 | 55 | 1397 | 130.71 | 3320 | GO | 4930 |

| 32* | 60 | 1524 | 61.9 | 1546 | 60 | 1524 | 140.2 | 3560 | GO | 5230 |

| 36* | 68 | 1727 | 69 | 1752 | 68 | 1727 | 153.94 | 3910 | GO | 6885 |

Class 600

Dimensions and Weights (*Gear Operated )

| Nom Size | Face to Face RF | Face to Face RTJ | Face to Face BW | Height.. | Handwheel Diameter..Weight.. | Weight | ||||

| in | in | mm | in | mm | in | mm | in | mm | mm | Kgs |

| 2 | 8.5 | 216 | 9.12 | 232 | 8.5 | 216 | 16.7 | 424 | 200 | 24 |

| 21.2 | 9.5 | 241 | 10.12 | 257 | 9.5 | 241 | 18.1 | 460 | 200 | 44 |

| 3 | 11.13 | 283 | 11.8 | 298 | 11.13 | 283 | 21 | 535 | 250 | 52 |

| 4 | 12 | 305 | 12.6 | 321 | 2 | 305 | 24.2 | 615 | 250 | 76 |

| 5 | 15 | 381 | 15.6 | 397 | 15 | 381 | 26.1 | 662 | 350 | 94 |

| 6 | 15.86 | 403 | 16.5 | 419 | 15.86 | 403 | 31.3 | 795 | 350 | 146 |

| 8 | 16.5 | 419 | 17.1 | 435 | 16.5 | 419 | 39.9 | 1012 | 400 | 218 |

| 10 | 18 | 457 | 18.6 | 473 | 18 | 457 | 48.5 | 1231 | 450 | 352 |

| 12 | 19.75 | 502 | 20.4 | 518 | 19.75 | 502 | 57 | 1450 | 500 | 472 |

| 14 | 30 | 762 | 30.6 | 778 | 30 | 762 | 64.8 | 1645 | 600 | 694 |

| 16 | 33 | 838 | 33.6 | 854 | 33 | 838 | 72.5 | 1841 | 600 | 1080 |

| 18 | 36 | 914 | 36.6 | 930 | 36 | 914 | 76.5 | 1943 | 680 | 1235 |

| 20 | 39 | 991 | 39.8 | 1010 | 39 | 991 | 84.8 | 2154 | 965 | 1655 |

| 24 | 45 | 1143 | 45.9 | 1165 | 45 | 1143 | 100.5 | 2553 | 915 | 2320 |

| 26* | 49 | 1244 | 49.8 | 1266 | 49 | 1244 | 108.3 | 2750 | GO | 3100 |

| 28* | 53 | 1346 | 53.9 | 1368 | 53 | 1346 | 122.05 | 3100 | GO | 3893 |

| 30* | 55 | 1397 | 56 | 1422 | 55 | 1397 | 130.71 | 3320 | GO | 4930 |

| 32* | 60 | 1524 | 61.9 | 1546 | 60 | 1524 | 140.2 | 3560 | GO | 5230 |

| 36* | 68 | 1727 | 69 | 1752 | 68 | 1727 | 153.94 | 3910 | GO | 6885 |

Class 900

Dimensions and Weights (*Gear Operated )

| Nom Size | Face to Face RF | Face to Face RTJ | Face to Face BW | Height.. | Handwheel Diameter..Weight.. | Weight | ||||

| in | in | mm | in | mm | in | mm | in | mm | mm | Kgs |

| 2 | 14.5 | 368 | 14.63 | 371 | 14.5 | 368 | 14.5 | 620 | 300 | 95 |

| 21.2 | 16.5 | 419 | 16.63 | 422 | 16.5 | 419 | 27.8 | 705 | 350 | 108 |

| 3 | 15 | 381 | 15.13 | 384 | 15 | 381 | 27.4 | 695 | 350 | 125 |

| 4 | 18 | 457 | 18.13 | 460 | 18 | 457 | 32.5 | 825 | 400 | 192 |

| 6 | 24 | 610 | 24.13 | 613 | 24 | 610 | 42 | 1065 | 500 | 378 |

| 8 | 29 | 737 | 29.13 | 740 | 29 | 737 | 52 | 1320 | 600 | 635 |

| 10 | 33 | 838 | 33.13 | 841 | 33 | 838 | 60.6 | 1540 | 750 | 900 |

| 12 | 38 | 965 | 38.13 | 968 | 38 | 965 | 72.5 | 1840 | 850 | 1550 |

| 14* | 40.5 | 1029 | 40.88 | 1038 | 40.5 | 1029 | 79.7 | 2025 | GO | 2170 |

| 16* | 44.5 | 1130 | 44.88 | 1140 | 44.5 | 1130 | 85.4 | 2170 | GO | 3070 |

| 18* | 48 | 1219 | 48.5 | 1232 | 48 | 1219 | 87.87 | 2232 | GO | 3930 |

| 20* | 52 | 1320 | 52.52 | 1334 | 52 | 1320 | 95.87 | 2435 | GO | 5120 |

| 24* | 61 | 1549 | 61.54 | 1563 | 61 | 1549 | 112.8 | 2865 | GO | 7800 |

Class 1500

Dimensions and Weights (*Gear Operated )

| Nom Size | Face to Face RF | Face to Face RTJ | Face to Face BW | Height.. | Handwheel Diameter..Weight.. | Weight | ||||

| in | in | mm | in | mm | in | mm | in | mm | mm | Kgs |

| 2 | 14.5 | 368 | 11.63 | 371 | 14.5 | 368 | 22 | 559 | 250 | 82 |

| 21.2 | 16.5 | 419 | 16.63 | 422 | 16.5 | 419 | 26.5 | 673 | 400 | 127 |

| 3 | 18.5 | 470 | 18.63 | 473 | 18.5 | 470 | 28 | 711 | 400 | 168 |

| 4 | 21.5 | 546 | 21.63 | 549 | 21.5 | 546 | 33 | 838 | 500 | 277 |

| 6 | 27.8 | 705 | 28 | 711 | 27.8 | 705 | 55 | 1397 | 600 | 640 |

| 8* | 32.8 | 832 | 33.13 | 841 | 32.8 | 832 | 71.8 | 1822 | GO | 1180 |

| 10* | 39 | 991 | 39.38 | 1000 | 39 | 991 | 80.8 | 2051 | GO | 2118 |

| 12* | 44.5 | 1130 | 45.13 | 1146 | 44.5 | 1130 | 84 | 2134 | GO | 3244 |

| 14* | 49.5 | 1257 | 50.25 | 1276 | 49.5 | 1257 | 89.3 | 2267 | GO | 3693 |

| 16* | 54.5 | 1384 | 55.38 | 1407 | 54.5 | 1384 | 95.3 | 2420 | GO | 4890 |

Class 2500

Dimensions and Weights (*Gear Operated )

| Nom Size | Face to Face RF | Face to Face RTJ | Face to Face BW | Height.. | Handwheel Diameter..Weight.. | Weight | ||||

| in | in | in | in | in | mm | Kgs | ||||

| 2 | 17.75 | 451 | 17.88 | 454 | 17.75 | 451 | 27.6 | 700 | 350 | 135 |

| 21.2 | 20 | 508 | 20.25 | 514 | 20 | 508 | 29.5 | 750 | 450 | 210 |

| 3 | 22.75 | 578 | 23 | 584 | 22.75 | 578 | 34.6 | 887 | 560 | 271 |

| 4 | 26.5 | 673 | 26.88 | 683 | 26.5 | 673 | 42.5 | 1079 | 720 | 506 |

| 6* | 36 | 914 | 36.5 | 927 | 36 | 914 | 53.9 | 1370 | GO | 1571 |

| 8* | 40.25 | 1022 | 40.88 | 1038 | 40.25 | 1022 | 60.5 | 1530 | GO | 2401 |

| 10* | 50 | 1270 | 50.88 | 1292 | 50 | 1270 | 80.5 | 2045 | GO | 4520 |