Carbon Steel Pipe

Stainless Steel Pipe

Fittings

OCTG

Steel Structure

Value-Added Products

Clad Pipe

Coated Steel Pipe

Technical Data

Photos

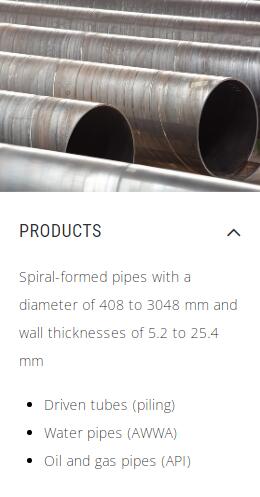

SSAW steel pipe (spiral submerged arc welded steel pipe) is formed by spiral bending of hot-rolled strip steel, and spiral seam steel pipe (also called spiral welded pipe, spiral pipe spiral steel pipe) is formed by automatic welding of submerged arc for inner and outer joints.

Material of SSAW Steel Pipe

| Uses | Standard |

| Steel Pipe for Fluid Service | GB/T 14291 |

| GB/T 3091 | |

| SY/T 5037 | |

| ASTM A53 | |

| BS EN10217-2 | |

| BS EN10217-5 | |

| Steel Pipe for Ordinary Structure | GB/T 13793 |

| SY/T 5040 | |

| ASTM A252 | |

| BS EN10219-1 | |

| BS EN10219-2 | |

| Line Pipe | GB/T 9711.1 |

| GB/T 9711.2 | |

| API 5L PSL1/2 | |

| Casing | API 5CT/ ISO 11960 PSL1 |

Chemical Analysis and Mechanical Properties of SSAW Steel Pipe

The raw material of the SSAW steel pipe includes steel coil, welding wire, flux. All of raw materials must be through strict physical and chemical maintenance before the investment.

| Standard | Grade | Chemical Composition(max)% | Mechanical Properties(min) | |||||

| C | Si | Mn | P | S | Tensile Strength(Mpa) | Yield Strength(Mpa) | ||

| API 5CT | h40 | – | – | – | – | 0.03 | 417 | 417 |

| J55 | – | – | – | – | 0.03 | 517 | 517 | |

| K55 | – | – | – | – | 0.3 | 655 | 655 | |

| API 5L PSL1 | A | 0.22 | – | 0.9 | 0.03 | 0.03 | 335 | 335 |

| B | 0.26 | – | 1.2 | 0.03 | 0.03 | 415 | 415 | |

| X42 | 0.26 | – | 1.3 | 0.03 | 0.03 | 415 | 415 | |

| X46 | 0.26 | – | 1.4 | 0.03 | 0.03 | 435 | 435 | |

| X52 | 0.26 | – | 1.4 | 0.03 | 0.03 | 460 | 460 | |

| X56 | 0.26 | – | 1.4 | 0.03 | 0.03 | 490 | 490 | |

| X60 | 0.26 | – | 1.4 | 0.03 | 0.03 | 520 | 520 | |

| X65 | 0.26 | – | 1.45 | 0.03 | 0.03 | 535 | 535 | |

| X70 | 0.26 | – | 1.65 | 0.03 | 0.03 | 570 | 570 | |

| API 5L PSL2 | B | 0.22 | 0.45 | 1.2 | 0.025 | 0.015 | 415 | 415 |

| X42 | 0.22 | 0.45 | 1.3 | 0.025 | 0.015 | 415 | 415 | |

| X46 | 0.22 | 0.45 | 1.4 | 0.025 | 0.015 | 435 | 435 | |

| X52 | 0.22 | 0.45 | 1.4 | 0.025 | 0.015 | 460 | 460 | |

| X56 | 0.22 | 0.45 | 1.4 | 0.025 | 0.015 | 490 | 490 | |

| X60 | 0.12 | 0.45 | 1.6 | 0.025 | 0.015 | 520 | 520 | |

| X65 | 0.12 | 0.45 | 1.6 | 0.025 | 0.015 | 535 | 535 | |

| X70 | 0.12 | 0.45 | 1.7 | 0.025 | 0.015 | 570 | 570 | |

| X80 | 0.12 | 0.45 | 1.85 | 0.025 | 0.015 | 625 | 625 | |

| ASTM A53 | A | 0.25 | 0.1 | 0.95 | 0.05 | 0.045 | 330 | 330 |

| B | 0.3 | 0.1 | 1.2 | 0.05 | 0.045 | 415 | 415 | |

| ASTM A252 | 1 | – | – | – | 0.05 | – | 345 | 345 |

| 2 | – | – | – | 0.05 | – | 414 | 414 | |

| 3 | – | – | – | 0.05 | – | 455 | 455 | |

| EN10217-1 | P195TR1 | 0.13 | 0.35 | 0.7 | 0.025 | 0.02 | 320 | 320 |

| P195TR2 | 0.13 | 0.35 | 0.7 | 0.025 | 0.02 | 320 | 320 | |

| P235TR1 | 0.16 | 0.35 | 1.2 | 0.025 | 0.02 | 360 | 360 | |

| P235TR2 | 0.16 | 0.35 | 1.2 | 0.025 | 0.02 | 360 | 360 | |

| P265TR1 | 0.2 | 0.4 | 1.4 | 0.025 | 0.02 | 410 | 410 | |

| P265TR2 | 0.2 | 0.4 | 1.4 | 0.025 | 0.02 | 410 | 410 | |

| EN10217-2 | P195GH | 0.13 | 0.35 | 0.7 | 0.025 | 0.02 | 320 | 320 |

| P235GH | 0.16 | 0.35 | 1.2 | 0.025 | 0.02 | 360 | 360 | |

| P265GH | 0.2 | 0.4 | 1.4 | 0.025 | 0.02 | 410 | 410 | |

| EN10217-5 | P235GH | 0.16 | 0.35 | 1.2 | 0.025 | 0.02 | 360 | 360 |

| P265GH | 0.2 | 0.4 | 1.4 | 0.025 | 0.02 | 410 | 410 | |

| EN10219-1 | S235JRH | 0.17 | – | 1.4 | 0.04 | 0.04 | 360 | 360 |

| S275JOH | 0.2 | – | 1.5 | 0.035 | 0.035 | 410 | 410 | |

| S275J2H | 0.2 | – | 1.5 | 0.03 | 0.03 | 410 | 410 | |

| S355JOH | 0.22 | 0.55 | 1.6 | 0.035 | 0.035 | 470 | 470 | |

| S355J2H | 0.22 | 0.55 | 1.6 | 0.03 | 0.03 | 470 | 470 | |

| S355K2H | 0.22 | 0.55 | 1.6 | 0.03 | 0.03 | 470 | 470 | |

Uses of SSAW Steel Pipe

for fluid service

for low pressure fluid service

for pipelines for low pressure fluid service

for pressure purposes

for pipe piles

Cold formed welded structural hollow sections of non-alloy and fine grain steels

for pipeline transportation system of petroleum and natural gas industries(Class A steel pipe)

for use as casing or tubing for wells of petroleum and natural gas industries

SSAW Pipe (HSAW Pipe) Manufacturing Process

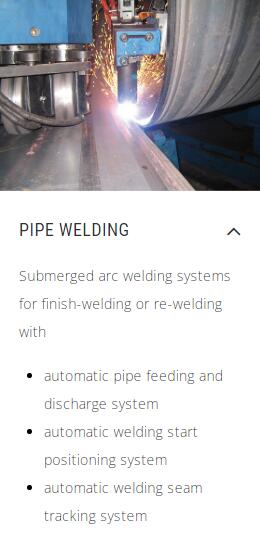

Spiral welded pipe production by submerged arc method is based on using tandem welding technique for joining inside and outside coil edges, which have been trimmed and beveled by carbide milling for high quality weld structure.

Spiral Seam Annealing Systems

Thermatool designs and manufactures Spiral Seam Annealing systems for producers of SAW (submerged arc welded) API line pipe.

Offering all the basic features and benefits of Thermatool seam annealing systems designed for operation on longitudinally welded API pipe, Thermatool Spiral Seam Annealing systems, however, require the installation of specially “shaped” inductors.

These are custom designed on CAD systems in order to precisely follow the helix angle for a specific pipe diameter.

Production Notes of SSAW Steel Pipe

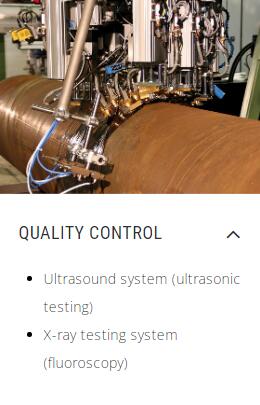

SSAW steel pipe in the production process, we need to pay attention to a series of matters. Except for the following test items, according to the API standard and other relevant standards and the special requirements of some users, but also the need for steel, steel pipe and other tests Destructive tests, including physical and chemical properties of the raw materials into the plant sampling, visual inspection of 100% steel .

A. Oiled marking: steel after passing were oiled to prevent corrosion, and according to user requirements for marking.

B. Leveling Milling: The flat steel anvil machine so that the original curl, and then through the edge milling machine for two-sided steel milling, so as to meet the requirements of the plate width, plate edge parallelism and groove shape.

C. Shear molding: the steel plate production line along the outer edge of the spiral curl into a tube.

D. Butt cut: double-sided submerged arc welding using advanced technology to pre-welding, internal welding, outside welding. The welded tube using a plasma-foot cut to specification length.

Out diameter Wall Thickness

219mm-3620mm 5mm-25.4mm

|

Out Diameter |

Wall Thickness (mm) |

|||||||||||||||||||

|

mm |

6 |

7 |

8 |

9 |

10 |

11 |

12 |

13 |

14 |

15 |

16 |

17 |

18 |

19 |

20 |

21 |

22 |

23 |

24 |

25 |

| 219.1 | . | . | . | . | ||||||||||||||||

| 273 | . | . | . | . | . | |||||||||||||||

|

323.9 |

. |

. |

. |

. |

. |

. |

. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

325 |

. |

. |

. |

. |

. |

. |

. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

355.6 |

. |

. |

. |

. |

. |

. |

. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

377 |

. |

. |

. |

. |

. |

. |

. |

. |

|

|

|

|

|

|

|

|

|

|

|

|

|

406.4 |

. |

. |

. |

. |

. |

. |

. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

426 |

. |

. |

. |

. |

. |

. |

. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

457 |

. |

. |

. |

. |

. |

. |

. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

478 |

. |

. |

. |

. |

. |

. |

. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

508 |

. |

. |

. |

. |

. |

. |

. |

|

. |

|

|

|

|

|

|

|

|

|

|

|

|

529 |

. |

. |

. |

. |

. |

. |

. |

|

. |

|

|

|

|

|

|

|

|

|

|

|

|

630 |

. |

. |

. |

. |

. |

. |

. |

|

. |

. |

|

|

|

|

|

|

|

|

|

|

|

711 |

. |

. |

. |

. |

. |

. |

. |

. |

. |

. |

. |

|

|

|

|

|

|

|

|

|

|

720 |

. |

. |

. |

. |

. |

. |

. |

. |

. |

. |

. |

|

|

|

|

|

|

|

|

|

|

813 |

|

. |

. |

. |

. |

. |

. |

. |

. |

. |

. |

. |

. |

|

|

|

|

|

|

|

|

820 |

|

. |

. |

. |

|

. |

. |

. |

. |

. |

. |

. |

. |

|

|

|

|

|

|

|

|

920 |

|

|

. |

. |

|

. |

. |

. |

. |

. |

. |

. |

. |

|

|

|

|

|

|

|

|

1020 |

|

|

. |

. |

. |

. |

. |

. |

. |

. |

. |

. |

. |

. |

. |

|

|

|

|

|

|

1220 |

|

|

. |

. |

. |

. |

. |

. |

. |

. |

. |

. |

. |

. |

. |

|

|

|

|

|

|

1420 |

|

|

|

. |

. |

. |

. |

. |

. |

. |

|

. |

. |

. |

. |

|

|

|

|

|

|

1620 |

|

|

|

|

. |

. |

. |

. |

. |

. |

. |

. |

. |

. |

. |

|

|

|

|

|

|

1820 |

|

|

|

|

|

. |

. |

. |

. |

. |

. |

. |

. |

. |

. |

|

|

|

|

|

|

2020 |

|

|

|

|

|

|

. |

. |

. |

. |

. |

. |

. |

. |

. |

|

|

|

|

|

|

2220 |

|

|

|

|

|

|

|

. |

. |

. |

. |

. |

. |

. |

. |

|

|

|

|

|

|

2500 |

|

|

|

|

|

|

|

. |

. |

. |

. |

. |

. |

. |

. |

. |

. |

. |

. |

. |

|

2540 |

|

|

|

|

|

|

|

|

. |

. |

. |

. |

. |

. |

. |

. |

. |

. |

. |

. |

|

3500 |

|

|

|

|

|

|

|

|

|

. |

. |

. |

. |

. |

. |

. |

. |

. |

. |

. |