From the point of view of the welding process. Regardless of whether it is a straight seam steel pipe or a spiral steel pipe, the welding method of the two is the same.

Read more

Squeeze amount refers to the amount of metal squeezed at the weld when the edge of the tube passes through the squeeze roll after high-frequency heating.

Read more

Under certain other conditions, increasing the welding speed will reduce the welding heat input, thereby reducing the weld width and penetration. Since the amount of welding wire metal deposition per unit length of the weld is inversely proportional to the welding speed, it also leads to The weld reinforcement is reduced.

Read more

Low temperature seamless steel pipe are mainly used in the production of ethylene, propylene, urea, synthetic ammonia, compound fertilizers, and other process equipment.

Read more

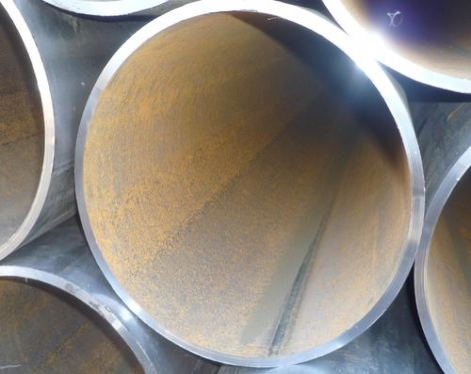

Long-distance oil and gas pipelines are an important way to ensure energy. In the anti-corrosion construction process of oil and gas pipelines, the surface treatment of straight seam steel pipes is one of the key factors that determine the anti-corrosion service life of the pipeline.

Read more

Thick-walled straight seam steel pipes are generally not magnetic or weakly magnetic, but if they are magnetic, they will not affect us during use, but for many manufacturers, it is still necessary to clean the magnetic properties of thick-walled straight seam steel pipes.

Read more