A500 ERW (Electric Resistance Welded) steel pipe refers to a type of steel pipe that is made using the electric resistance welding process and meets the specifications outlined in ASTM A500.

Read more

Theory and practice have proven that ERW tubes have the characteristics of reliability, safety and economy in oil and gas transportation applications.

Read more

The flattening test of ERW welded pipes can effectively and quickly uate the quality of welds and raw materials.

Read more

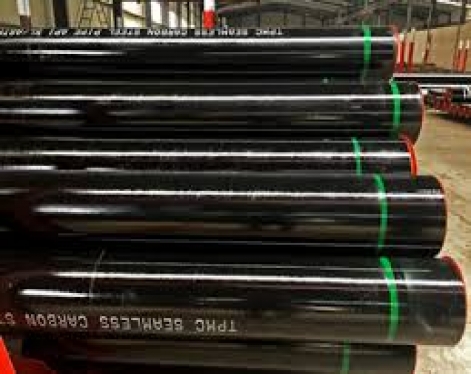

ASTM black steel pipe refers to a black steel pipe that conforms to the ASTM (American Society for Testing and Materials) standards.

Read more

MS ERW pipe full form is mild steel electric resistance welded pipe. It refers to a steel pipe produced from low carbon steel billet through resistance welding.

Read more

ERW pipe for fire fighting refer to a steel pipe made by resistance welding and used in the fire fighting field.

Read more