1. What is API 5L implementation standard?

API 5L is a standard developed by the American Petroleum Institute to specify the manufacturing and inspection standards for pipeline pipes. This standard specifies the requirements for size, shape, mechanical properties and materials of pipeline steel pipes. Compared with ASTM and ASME, API 5L pays more attention to the practicality and functionality of steel pipes, so it is more widely used.(1)What is pipeline pipe?

Line pipe is a kind of pipeline used to transport fluid media, mainly used in petroleum, natural gas, chemical industry, electric power and other industries. The main function of line pipes is to transport media such as oil, natural gas or water from the extraction site to the corresponding industrial facilities, forming a huge transportation network.Line pipes are usually divided into two types: seamless pipes and welded pipes. Both ends can be made into flat ends, threaded ends or socket ends. The connection methods include end welding, coupling connection, socket connection, etc. Line pipes have various standards and materials (steel grades), including API standards, requirements for different thicknesses, and materials suitable for specific environments (such as acidic environments or marine environments), such as L245, L290, L360, L418, L480, G.R B, X42, X46, X56, X65, X70, X80, X100, etc. There are currently three commonly used oil pipeline welded pipes, namely spiral submerged arc welded pipe (SSAW), straight seam submerged arc welded pipe (LSAW), and electric resistance welded pipe (ERW). Seamless steel pipes are generally selected when the pipe diameter is less than 152mm.

(2)API 5L steel grade

API 5L standard steel pipe raw material steel grades include GR.B, X42, X46, X52, X56, X60, X70, and X120 pipeline steel. Different steel grades of steel pipes have different requirements for raw materials and production, but the carbon equivalent between different steel grades is strictly controlled.

2. What is API 5L ERW Pipe?

API 5L ERW Pipe is a resistance welded pipe produced according to the API 5L executive marking standards.(1)What is resistance welding?

Resistance welding is a manufacturing process and technology that uses heating to join metal or other thermoplastic materials such as plastics. It is a method of welding by applying pressure through electrodes after the workpieces are assembled, and using resistance heat generated by current passing through the contact surface of the joint and adjacent areas.(2) Characteristics of resistance welding

Advantages:① When the nugget is formed, it is always surrounded by a plastic ring, the molten metal is isolated from the air, and the metallurgical process is simple.

② The heating time is short and the heat is concentrated, so the heat-affected zone is small, deformation and stress are also small, and there is usually no need to arrange correction and heat treatment processes after welding.

③ There is no need for filler metals such as welding wires and electrodes, as well as welding materials such as oxygen, acetylene, and hydrogen, so the welding cost is low.

④Simple operation, easy to implement mechanization and automation, and improved working conditions.

⑤ High productivity, no noise and no harmful gases. In mass production, it can be integrated into the assembly line together with other manufacturing processes. However, flash butt welding needs to be isolated due to spark splash.

Shortcomings:

① There is currently a lack of reliable non-destructive testing methods, and welding quality can only be checked by destructive testing of process samples and workpieces, as well as guaranteed by various monitoring technologies.

② Point and seam welded lap joints not only increase the weight of the component, but also cause the angle formed around the welding nugget of the two plates, resulting in low tensile strength and fatigue strength of the joint.

③The equipment has high power, and a high degree of mechanization and automation, which makes the equipment cost high and maintenance difficult, and the commonly used high-power single-phase AC welding machine is not conducive to the balanced operation of the power grid.

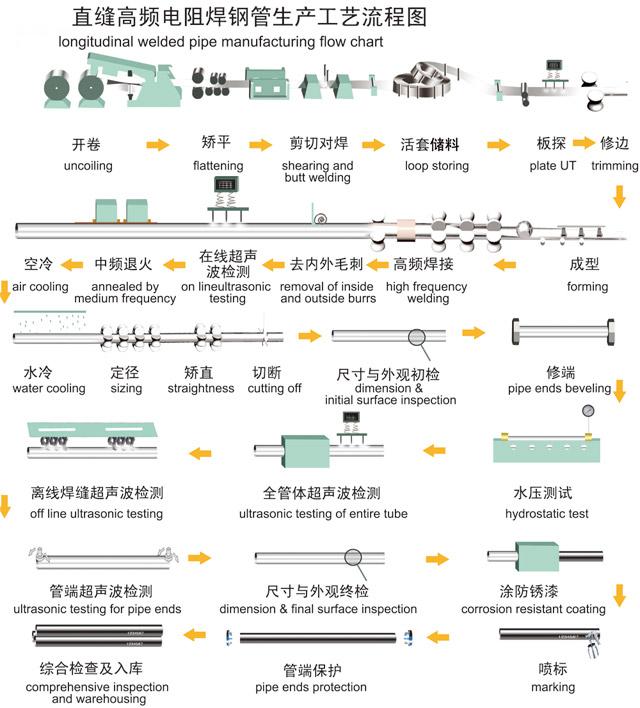

(3)ERW pipe production process

(4)Characteristics and applications of ERW pipe

ERW welded pipe is a resistance welded steel pipe without filler metal. The outer surface is very smooth. It is difficult to find the weld position from the outer surface alone. It is easy to apply anti-corrosion coating and has high dimensional accuracy. But if you want to obtain high-quality ERW welded pipes, API 5L ERW pipe manufacturers must have mature pipe-making processes, complete and reliable quality control systems and quality assurance systems.The application of ERW steel pipes is extensive, with uses ranging from oil and gas to construction and infrastructure projects.3.API 5L ERW Pipe Specification

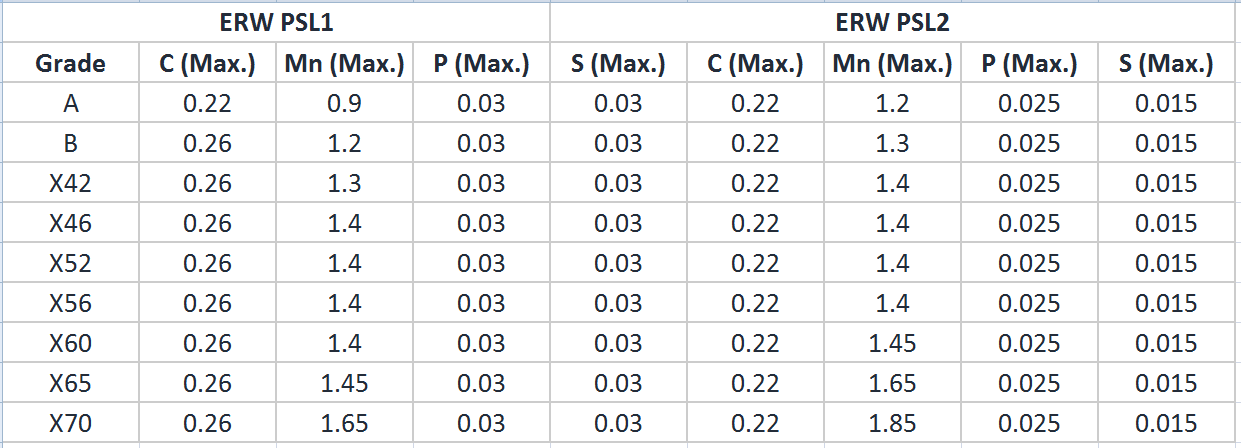

(1)API 5L Welded Pipe Chemical Composition

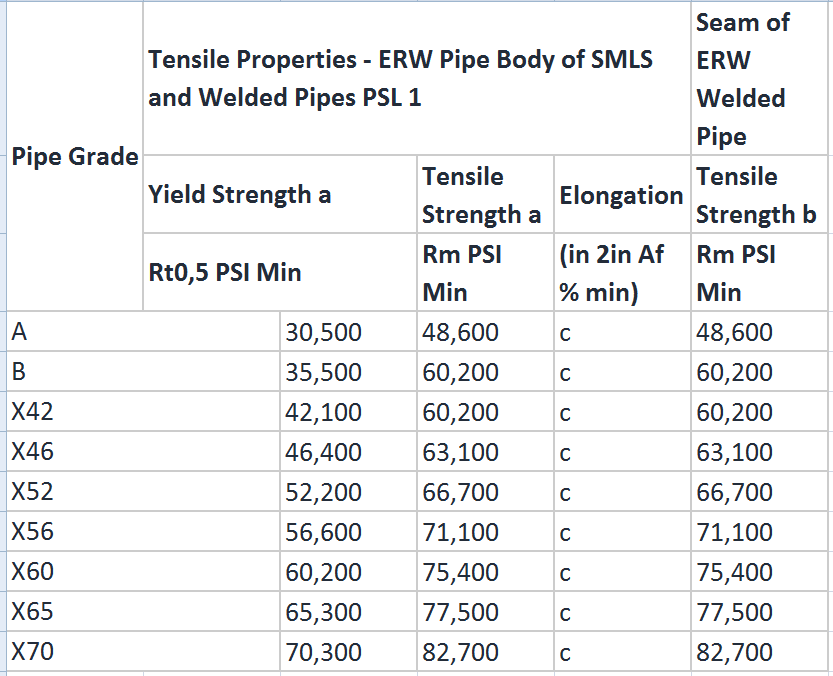

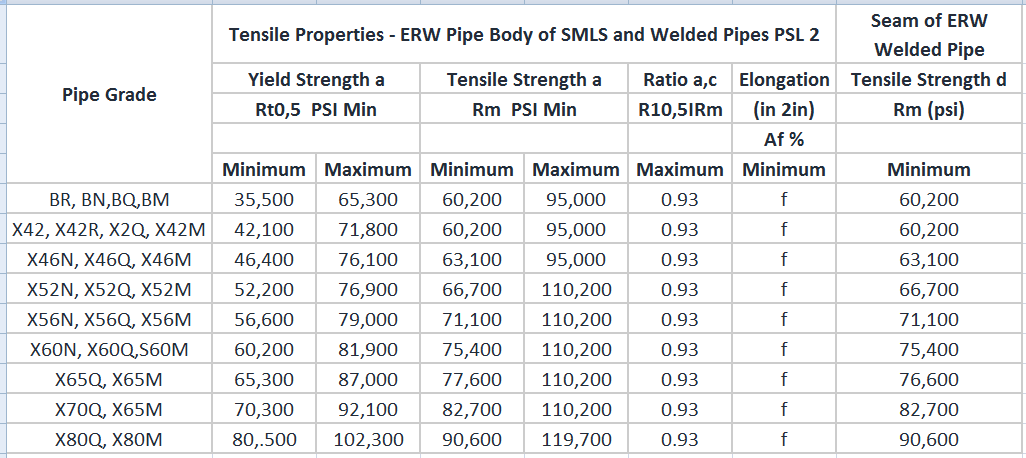

(2) API 5L ERW Pipe Yield Strength & Tensile Strength - PSL1 and PSL2

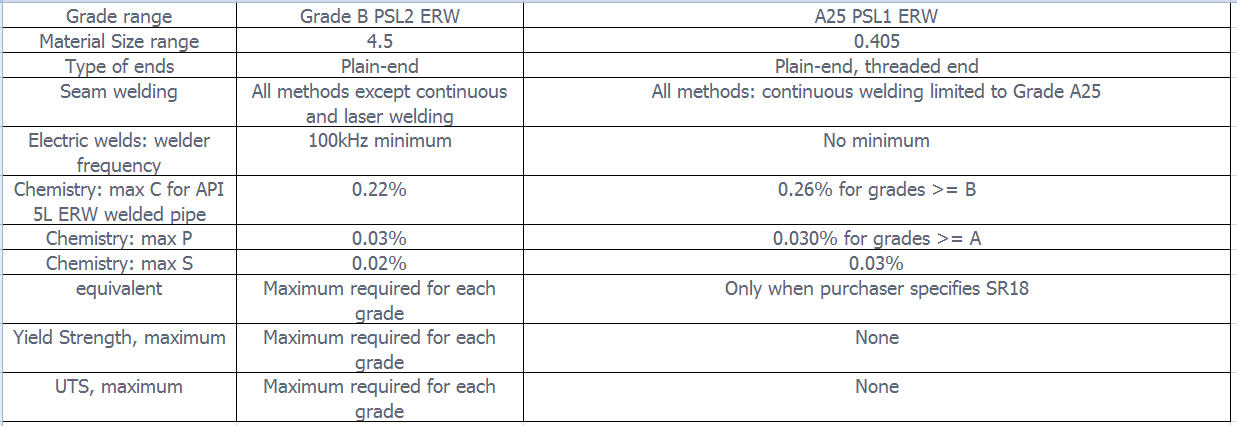

(3) Difference Between PSL1 and PSL2