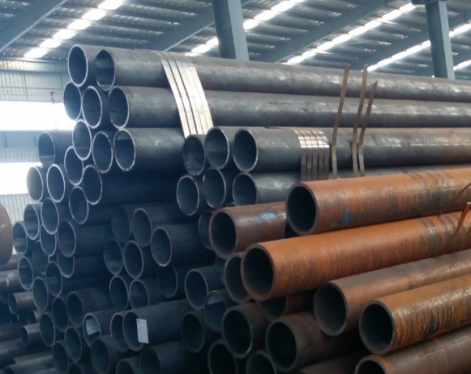

Seamless steel pipes (SMLS) for ships have the following characteristics and applications:

Characteristics:

1. High strength

Ships operate in the marine environment and need to withstand various dynamic and static loads, such as the weight of the hull itself, the weight of cargo, the impact of waves, etc. Therefore, seamless steel pipes for ships must have sufficient strength to ensure the safety and stability of the ship structure.

Generally speaking, the yield strength and tensile strength of seamless steel pipes for ships are relatively high, which can meet the strength requirements of ship structures.

2. Good corrosion resistance

The marine environment contains a large amount of salt and other corrosive substances, which are highly corrosive to metal materials. Therefore, seamless steel pipes for ships must have good corrosion resistance to extend their service life.

Usually, seamless steel pipes for ships will adopt some special anti-corrosion measures, such as galvanizing, painting, and coating with anti-corrosion materials to improve their corrosion resistance.

3. Good welding performance

During the construction of ships, seamless steel pipes require a lot of welding operations. Therefore, seamless steel pipes for ships must have good welding performance to ensure the quality and strength of welded joints.

Generally speaking, the welding performance of seamless steel pipes for ships mainly depends on their chemical composition and manufacturing process. The use of appropriate welding materials and welding processes can ensure the welding quality of seamless steel pipes for ships.

4. High dimensional accuracy

Ship structures have relatively high dimensional accuracy requirements for seamless steel pipes, because excessive dimensional deviations may affect the structural strength and sealing of the ship. Therefore, seamless steel pipes for ships must have high dimensional accuracy to ensure that they can meet the requirements of ship construction.

Generally speaking, the dimensional tolerance of seamless steel pipes for ships can be controlled within a smaller range to ensure their dimensional accuracy.

5. Good machinability

During the shipbuilding process, seamless steel pipes need to undergo various processing operations, such as cutting, bending, stamping, etc. Therefore, seamless steel pipes for ships must have good machinability to ensure that they can meet the requirements of shipbuilding.

Generally speaking, the machinability of seamless steel pipes for ships mainly depends on their materials and manufacturing processes. The use of appropriate processing methods and tools can ensure the processing quality of seamless steel pipes for ships.

Application:

1. Hull structure

The hull structure of a ship is mainly composed of steel plates and seamless steel pipes. Seamless steel pipes are mainly used in the hull structure to manufacture structural parts such as the hull frame, ribs, longitudinal girders, and pipe fittings used to connect various parts of the hull.

The high strength and good corrosion resistance of seamless steel pipes for ships can ensure the safety and stability of the hull structure, and also extend the service life of the ship.

2. Ship piping system

The ship's piping system is mainly used to transport various fluid media, such as fuel, lubricating oil, seawater, fresh water, etc. Seamless steel pipes are mainly used in the ship's piping system to manufacture various pipes, such as fuel pipes, lubricating oil pipes, seawater pipes, fresh water pipes, etc.

The good corrosion resistance and high dimensional accuracy of seamless steel pipes for ships can ensure the sealing and reliability of the pipeline system, and can also reduce the maintenance cost of the pipeline system.

3. Ship mechanical parts

The mechanical parts of the ship mainly include engines, propellers, steering gears, etc. Seamless steel pipes are mainly used to manufacture various pipes in ship mechanical parts, such as engine exhaust pipes, air intake pipes, cooling water pipes, etc., as well as propeller shaft pipes, steering gear oil pipes, etc.

The high strength and good welding performance of seamless steel pipes for ships can ensure the reliability and safety of mechanical parts, and also improve the service life of mechanical parts.

In short, seamless steel pipes for ships are an indispensable and important material in shipbuilding. Their high strength, good corrosion resistance, good welding performance, high dimensional accuracy and good machinability make them widely used in hull structures, ship piping systems and ship mechanical parts.

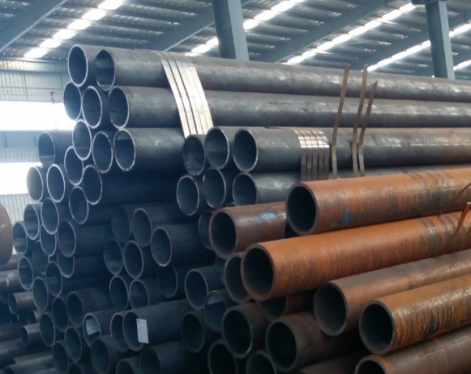

Characteristics:

1. High strength

Ships operate in the marine environment and need to withstand various dynamic and static loads, such as the weight of the hull itself, the weight of cargo, the impact of waves, etc. Therefore, seamless steel pipes for ships must have sufficient strength to ensure the safety and stability of the ship structure.

Generally speaking, the yield strength and tensile strength of seamless steel pipes for ships are relatively high, which can meet the strength requirements of ship structures.

2. Good corrosion resistance

The marine environment contains a large amount of salt and other corrosive substances, which are highly corrosive to metal materials. Therefore, seamless steel pipes for ships must have good corrosion resistance to extend their service life.

Usually, seamless steel pipes for ships will adopt some special anti-corrosion measures, such as galvanizing, painting, and coating with anti-corrosion materials to improve their corrosion resistance.

3. Good welding performance

During the construction of ships, seamless steel pipes require a lot of welding operations. Therefore, seamless steel pipes for ships must have good welding performance to ensure the quality and strength of welded joints.

Generally speaking, the welding performance of seamless steel pipes for ships mainly depends on their chemical composition and manufacturing process. The use of appropriate welding materials and welding processes can ensure the welding quality of seamless steel pipes for ships.

4. High dimensional accuracy

Ship structures have relatively high dimensional accuracy requirements for seamless steel pipes, because excessive dimensional deviations may affect the structural strength and sealing of the ship. Therefore, seamless steel pipes for ships must have high dimensional accuracy to ensure that they can meet the requirements of ship construction.

Generally speaking, the dimensional tolerance of seamless steel pipes for ships can be controlled within a smaller range to ensure their dimensional accuracy.

5. Good machinability

During the shipbuilding process, seamless steel pipes need to undergo various processing operations, such as cutting, bending, stamping, etc. Therefore, seamless steel pipes for ships must have good machinability to ensure that they can meet the requirements of shipbuilding.

Generally speaking, the machinability of seamless steel pipes for ships mainly depends on their materials and manufacturing processes. The use of appropriate processing methods and tools can ensure the processing quality of seamless steel pipes for ships.

Application:

1. Hull structure

The hull structure of a ship is mainly composed of steel plates and seamless steel pipes. Seamless steel pipes are mainly used in the hull structure to manufacture structural parts such as the hull frame, ribs, longitudinal girders, and pipe fittings used to connect various parts of the hull.

The high strength and good corrosion resistance of seamless steel pipes for ships can ensure the safety and stability of the hull structure, and also extend the service life of the ship.

2. Ship piping system

The ship's piping system is mainly used to transport various fluid media, such as fuel, lubricating oil, seawater, fresh water, etc. Seamless steel pipes are mainly used in the ship's piping system to manufacture various pipes, such as fuel pipes, lubricating oil pipes, seawater pipes, fresh water pipes, etc.

The good corrosion resistance and high dimensional accuracy of seamless steel pipes for ships can ensure the sealing and reliability of the pipeline system, and can also reduce the maintenance cost of the pipeline system.

3. Ship mechanical parts

The mechanical parts of the ship mainly include engines, propellers, steering gears, etc. Seamless steel pipes are mainly used to manufacture various pipes in ship mechanical parts, such as engine exhaust pipes, air intake pipes, cooling water pipes, etc., as well as propeller shaft pipes, steering gear oil pipes, etc.

The high strength and good welding performance of seamless steel pipes for ships can ensure the reliability and safety of mechanical parts, and also improve the service life of mechanical parts.

In short, seamless steel pipes for ships are an indispensable and important material in shipbuilding. Their high strength, good corrosion resistance, good welding performance, high dimensional accuracy and good machinability make them widely used in hull structures, ship piping systems and ship mechanical parts.