Oil casing is a large-diameter pipe that plays a role in fixing the walls or wellbore of oil and natural gas wells. The casing is inserted into the wellbore and fixed with cement to prevent the wellbore from separating the rock formations and the wellbore from collapsing, and to ensure the circulation of drilling mud to facilitate drilling and mining.

Oil casing classification

Casing can be divided into: conduit, surface casing, technical casing and oil layer casing according to usage.

Surface requirements for oil casing

1. The internal and external surfaces of the casing shall be free of folds, hairlines, separation layers, cracks, folds and scars. These defects should be completely removed to a depth not exceeding 12.5% of the nominal wall thickness.

2. The outer surface of the coupling should not have defects such as folds, hair lines, separation layers, cracks, folds, scars, etc.

3. The thread surface of the casing and coupling should be smooth, and no burrs, tears or other defects sufficient to interrupt the threads will affect the strength and tight connection.

API standards for Casing

API, shorted for American Petroleum Institute, is considered as one of the most authoritative and comprehensive principles for the oil and gas industry. Products complied with API standards are always thought of reliable quality. Under the general standards, there are some subordinated specifications drafted for each specific OCTG product, such as API 5B, API 5CT, API 5D, API 5L and so on.

API 5B and 5CT are mainly used for tubing and casing, standardizing the chemical properties, steel grades, manufacturing methods, color coding, heat treatment, inspection, etc. Tubing and casing are supposed to withstand specific pressure in transportation of oil or natural gas, which means the steel material should have proper yield strength. Therefore, API 5B and 5CT lay specific standards of steel grade for tubing and casing to meet the general application purpose.

According to the strength of the steel itself, the casing can be divided into different steel grades, namely J55, K55, N80, L80, C90, T95, P110, Q125, V150, etc. Different well conditions and well depths require different steel grades. In corrosive environments, the casing itself is also required to have corrosion resistance. In places with complex geological conditions, the casing is also required to have extrusion resistance.

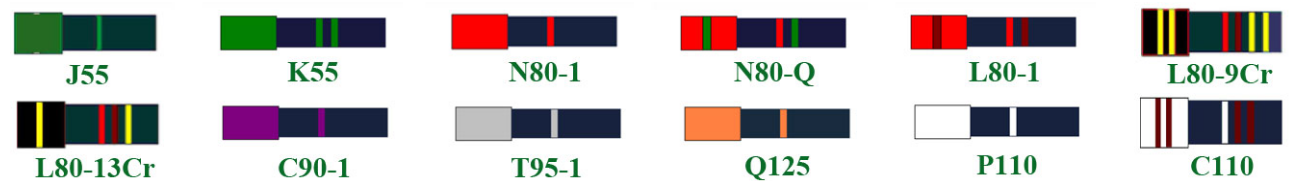

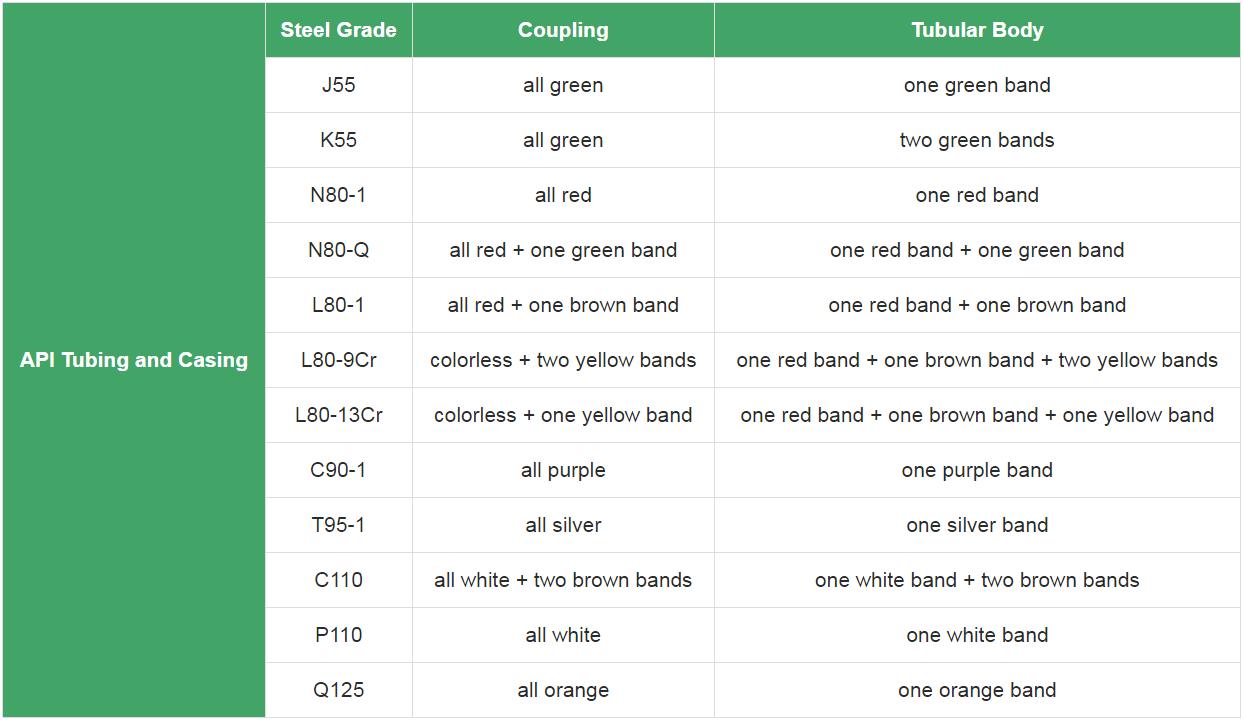

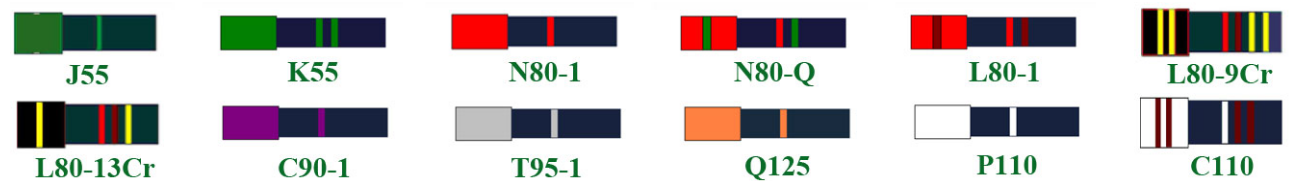

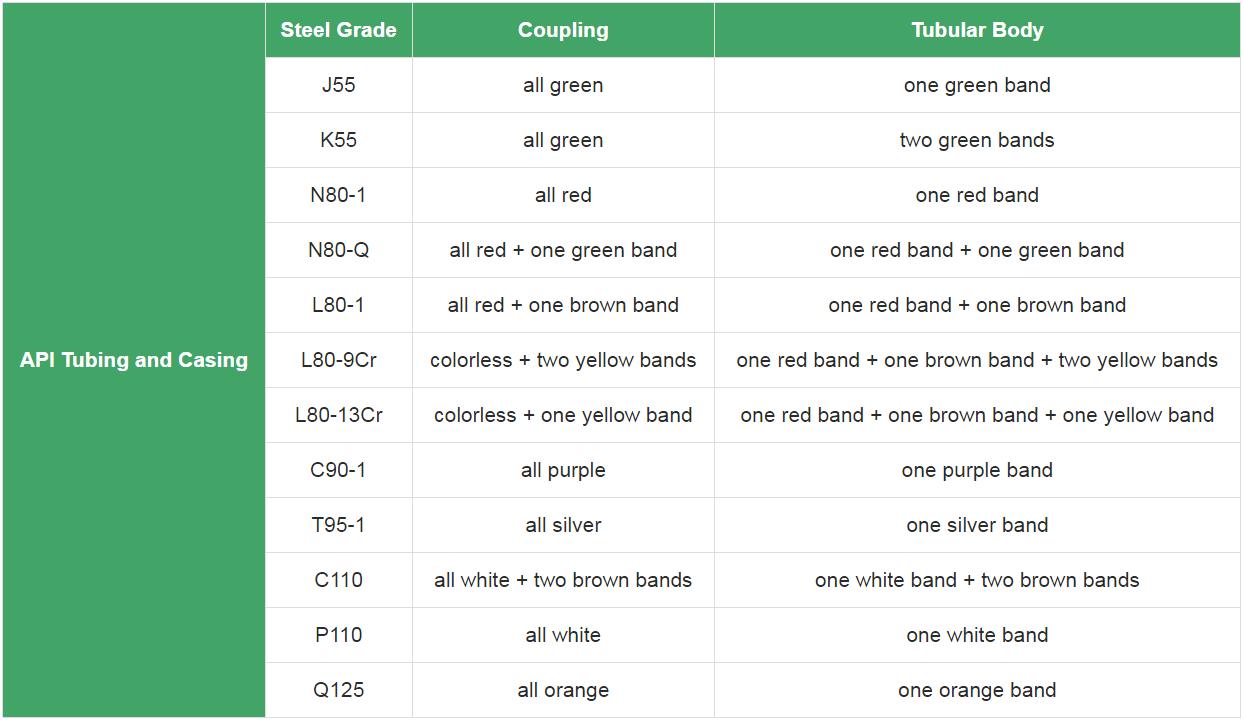

Grades of OCTG products and steel grade color codes

In order to clearly distinguish the steel grade, tubing, casing and its coupling should be painted with color codes respectively. Color bands should be painted on tubing and casing body longer than 600mm to either end. The whole outer-body of the coupling needs to be painted color and then color codes.

Oil casing classification

Casing can be divided into: conduit, surface casing, technical casing and oil layer casing according to usage.

Surface requirements for oil casing

1. The internal and external surfaces of the casing shall be free of folds, hairlines, separation layers, cracks, folds and scars. These defects should be completely removed to a depth not exceeding 12.5% of the nominal wall thickness.

2. The outer surface of the coupling should not have defects such as folds, hair lines, separation layers, cracks, folds, scars, etc.

3. The thread surface of the casing and coupling should be smooth, and no burrs, tears or other defects sufficient to interrupt the threads will affect the strength and tight connection.

API standards for Casing

API, shorted for American Petroleum Institute, is considered as one of the most authoritative and comprehensive principles for the oil and gas industry. Products complied with API standards are always thought of reliable quality. Under the general standards, there are some subordinated specifications drafted for each specific OCTG product, such as API 5B, API 5CT, API 5D, API 5L and so on.

API 5B and 5CT are mainly used for tubing and casing, standardizing the chemical properties, steel grades, manufacturing methods, color coding, heat treatment, inspection, etc. Tubing and casing are supposed to withstand specific pressure in transportation of oil or natural gas, which means the steel material should have proper yield strength. Therefore, API 5B and 5CT lay specific standards of steel grade for tubing and casing to meet the general application purpose.

According to the strength of the steel itself, the casing can be divided into different steel grades, namely J55, K55, N80, L80, C90, T95, P110, Q125, V150, etc. Different well conditions and well depths require different steel grades. In corrosive environments, the casing itself is also required to have corrosion resistance. In places with complex geological conditions, the casing is also required to have extrusion resistance.

Grades of OCTG products and steel grade color codes

In order to clearly distinguish the steel grade, tubing, casing and its coupling should be painted with color codes respectively. Color bands should be painted on tubing and casing body longer than 600mm to either end. The whole outer-body of the coupling needs to be painted color and then color codes.

Previous:Hot rolled steel sheet pile