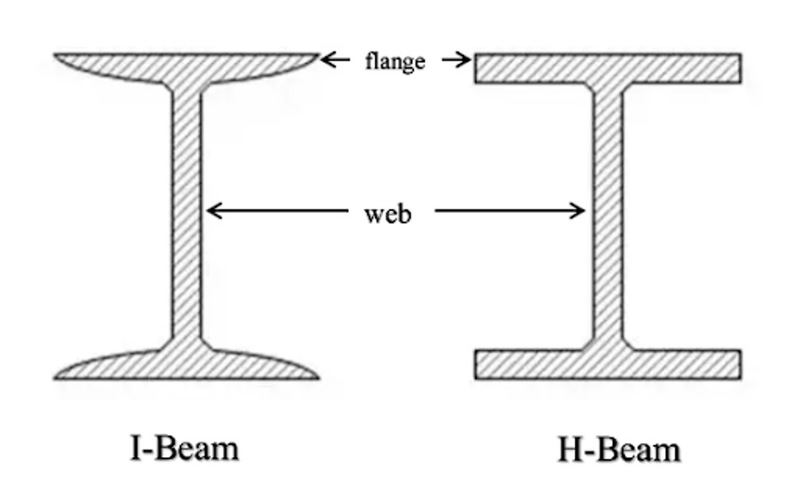

In the construction material market, steel profiles have become one of the indispensable raw materials for the structure and construction of various projects. Among the common steel profiles, such as U, V, I, and H shapes, two of them—I and H-beams—are often confused due to their similar shapes. However, the differences between them are not only in appearance but also in some important technical characteristics, which determine their adaptability in use. Let's delve into every detail to better understand the differences between I-beam and H-beam.

H-beams offer several advantages in construction. First, their strong bending strength allows architects to create stable and reliable structures, which is particularly important for projects that require stability, such as high-rise buildings and bridges.

Second, the construction process of H-beams is simple, and on-site assembly is easier and faster. This characteristic helps save costs and improve the efficiency of construction projects. Finally, the lightweight nature of H-beams reduces the weight of the entire structure, which has a positive impact on foundation requirements and material costs.

The flexibility of H-beams makes them suitable for many applications. In the construction industry, they are commonly used for the framework of buildings, such as columns, beams, and brackets. H-beams are also widely used in bridge construction due to their excellent durability and stability.

In addition, they are used in many industrial projects, including warehouses, factories, and power plants. The adaptability and durability of H-beams make them a preferred choice for both small and large construction projects.

To calculate the weight of H-beams, you can use the following formula: P (kg/m) = 0.785 x Cross-sectional area

Specifically:

Cross-sectional area (A) = [t1 (H – 2t2) + 2Bt2 + 0.858r^2] / 100 (cm^3).

H is the height of the H-beam.

B is the width of the flange of the H-beam.

t1: The thickness of the web.

t2: The thickness of the flange.

r: The radius of the inner fillet of the H-beam.

According to the collected information, the length of an H-beam is approximately between 6 meters and 15 meters. In fact, the product length of H-beams is usually 6 meters and 12 meters. The 12-meter H-beam is the most popular choice.

For H-beams with special dimensions or those that do not conform to standard specifications, they are usually discussed specifically between the purchaser and the manufacturer. If H-beams cannot be produced domestically, they will be imported.

At present, H-beams are a series of products, including H100, H125, H150, H200, H250, H300, H350, H400, etc., widely used in industrial and construction fields. Almost all of these models comply with international standards and are widely used in industrial and construction fields.

H-beams imported from countries such as Taiwan, Russia, China, Japan, the United Kingdom, and the United States.

Standards for H-beams include: ATSM, DIN, ANSI, EN, GOST 380-88, JIS G3101, SB410, 3010.

The grades of H-beams will be: S355JO, S275, S275JR, S275JO, S235, S235JR, S235JO, ASTM A36, JIS G3101 SS400, Q345B, A572 Gr50, S355, S355JR.

Russian H-beams will have the grade CT3, with the standard GOST 380-88.

Japanese H-beams will have the grade SS400, with the standard SB410, 3010.

Chinese H-beams will have the grades SS400, Q345B, with the standard JIS G3101, SB410, 3010.

American H-beams will have the grade A36, with the standard ATSM A36.

The weight of I-beams depends on their specific dimensions and other factors. Generally, the weight of I-beams is calculated based on a specific unit of length, usually 1 meter or 1 foot. To accurately calculate the weight of I-beams, you need to know their specific dimensions (length, thickness, width) and use these parameters to calculate the weight according to the specific specifications of the material.

For example, the formula for calculating the weight of I-beams is:

Weight = Thickness × Width × Length × Specific Gravity of Steel

The specific gravity and other technical parameters of the steel are usually provided by the manufacturer or can be found in the technical specification sheet. This helps to calculate the specific weight of a specific section of I-beam according to its technical specifications.

The quality of I-beams can be calculated using the following formula:

Quality = Thickness × Width × Length × Density of Steel

Where:

Thickness: The thickness of the web or flange of the I-beam (usually in millimeters or inches).

Width: The transverse dimension of the I-beam (usually in millimeters or inches).

Length: The length of the I-beam section (usually in meters or feet).

Density of Steel: The density of steel, usually in kilograms per cubic meter or pounds per cubic inch.

This formula will provide you with the quality of a section of I-beam based on its specific dimensions and the density of that type of steel. The density of steel can usually be found in the manufacturer's technical documents or data sheets.

I-beams from different countries and regions are classified according to their source and production standards, as follows:

Russian grades: CT3, etc., produced according to the GOST 380-88 standard.

Japanese grades: SS400, etc., produced according to the SB410, JIS G 3101, 3010 standards.

Chinese grades: Q235B, SS400, etc., produced according to the JIS G3101, SB410 standards.

American I-beams: A36, produced according to the ASTM A36 standard.

Each grade of steel has different sources and production standards, which may affect the specific characteristics of the steel and determine the appropriate use according to the specific needs and purposes of the investor.

These differences not only affect the choice between I and H steel profiles but also determine the efficiency and safety of construction projects.

H steel profiles have significant lateral load-bearing capacity and are generally favored in many projects, from residential buildings, prefabricated structures to high-rise buildings and large bridges. This is due to their greater ability to withstand pressure than I steel profiles, making them the preferred choice in situations that require high load-bearing capacity.

At the same time, I steel profiles also have a wide range of applications, similar to H steel profiles, used in various projects from residential buildings, prefabricated structures to high-rise buildings and bridges. However, due to their lightweight design, I steel profiles are usually considered first in projects that require a lightweight structure and no large load pressure.

The choice between I and H steel profiles usually depends on the specific requirements of each project, thus determining which type of steel profile is more suitable to ensure efficiency and safety during use.

Due to their greater weight and structure, the price of H steel profiles is usually higher than that of I steel profiles. This leads to the average consumption of H steel profiles in the market being greater than that of I steel profiles.

The price difference between these two types of steel profiles depends on many factors, including specific dimensions, quality, and market conditions. However, for the same quality, characteristics, and equal mass of a certain quality, the price of H steel profiles is usually higher because their raw materials and production requirements are more complex.

1. H Beam

(1) What is an H-beam?

The H-beam, also known as H-steel column, is a widely used structural element in construction. It is named H because part of its shape resembles the letter "H" in Vietnamese. Architects and engineers prefer to use H-beams because they have good bending resistance, simple construction, cost savings, and a lightweight structure.Suppliers and manufacturers of H-beams play an important role in providing high-quality steel to meet the needs of different construction projects.

(2) Advantages of H-beams in construction

H-beams offer several advantages in construction. First, their strong bending strength allows architects to create stable and reliable structures, which is particularly important for projects that require stability, such as high-rise buildings and bridges.Second, the construction process of H-beams is simple, and on-site assembly is easier and faster. This characteristic helps save costs and improve the efficiency of construction projects. Finally, the lightweight nature of H-beams reduces the weight of the entire structure, which has a positive impact on foundation requirements and material costs.

(3) Applications of H-beams

The flexibility of H-beams makes them suitable for many applications. In the construction industry, they are commonly used for the framework of buildings, such as columns, beams, and brackets. H-beams are also widely used in bridge construction due to their excellent durability and stability.In addition, they are used in many industrial projects, including warehouses, factories, and power plants. The adaptability and durability of H-beams make them a preferred choice for both small and large construction projects.

(4) How to calculate the weight of H-beams

To calculate the weight of H-beams, you can use the following formula: P (kg/m) = 0.785 x Cross-sectional areaSpecifically:

Cross-sectional area (A) = [t1 (H – 2t2) + 2Bt2 + 0.858r^2] / 100 (cm^3).

H is the height of the H-beam.

B is the width of the flange of the H-beam.

t1: The thickness of the web.

t2: The thickness of the flange.

r: The radius of the inner fillet of the H-beam.

(5) Dimensions of H-beams

According to the collected information, the length of an H-beam is approximately between 6 meters and 15 meters. In fact, the product length of H-beams is usually 6 meters and 12 meters. The 12-meter H-beam is the most popular choice.For H-beams with special dimensions or those that do not conform to standard specifications, they are usually discussed specifically between the purchaser and the manufacturer. If H-beams cannot be produced domestically, they will be imported.

(6) Standards for H-beams

At present, H-beams are a series of products, including H100, H125, H150, H200, H250, H300, H350, H400, etc., widely used in industrial and construction fields. Almost all of these models comply with international standards and are widely used in industrial and construction fields.H-beams imported from countries such as Taiwan, Russia, China, Japan, the United Kingdom, and the United States.

Standards for H-beams include: ATSM, DIN, ANSI, EN, GOST 380-88, JIS G3101, SB410, 3010.

The grades of H-beams will be: S355JO, S275, S275JR, S275JO, S235, S235JR, S235JO, ASTM A36, JIS G3101 SS400, Q345B, A572 Gr50, S355, S355JR.

Russian H-beams will have the grade CT3, with the standard GOST 380-88.

Japanese H-beams will have the grade SS400, with the standard SB410, 3010.

Chinese H-beams will have the grades SS400, Q345B, with the standard JIS G3101, SB410, 3010.

American H-beams will have the grade A36, with the standard ATSM A36.

2. I Beam

(1) What is I-beam?

I-beam, also known as I-beam, is a product manufactured by hot rolling in an "I" shaped mold. With a cross-section resembling the letter "I", this type of steel is commonly used in the construction and industrial design fields. Although its shape is similar to that of H-beam, it is usually important to accurately distinguish between these two types of steel because their properties and uses are different.

(2) Method of calculating the weight of I-beams

The weight of I-beams depends on their specific dimensions and other factors. Generally, the weight of I-beams is calculated based on a specific unit of length, usually 1 meter or 1 foot. To accurately calculate the weight of I-beams, you need to know their specific dimensions (length, thickness, width) and use these parameters to calculate the weight according to the specific specifications of the material.For example, the formula for calculating the weight of I-beams is:

Weight = Thickness × Width × Length × Specific Gravity of Steel

The specific gravity and other technical parameters of the steel are usually provided by the manufacturer or can be found in the technical specification sheet. This helps to calculate the specific weight of a specific section of I-beam according to its technical specifications.

(3) Quality of I-beams

The quality of I-beams can be calculated using the following formula:Quality = Thickness × Width × Length × Density of Steel

Where:

Thickness: The thickness of the web or flange of the I-beam (usually in millimeters or inches).

Width: The transverse dimension of the I-beam (usually in millimeters or inches).

Length: The length of the I-beam section (usually in meters or feet).

Density of Steel: The density of steel, usually in kilograms per cubic meter or pounds per cubic inch.

This formula will provide you with the quality of a section of I-beam based on its specific dimensions and the density of that type of steel. The density of steel can usually be found in the manufacturer's technical documents or data sheets.

(4) Grades of I-beams

I-beams from different countries and regions are classified according to their source and production standards, as follows:Russian grades: CT3, etc., produced according to the GOST 380-88 standard.

Japanese grades: SS400, etc., produced according to the SB410, JIS G 3101, 3010 standards.

Chinese grades: Q235B, SS400, etc., produced according to the JIS G3101, SB410 standards.

American I-beams: A36, produced according to the ASTM A36 standard.

Each grade of steel has different sources and production standards, which may affect the specific characteristics of the steel and determine the appropriate use according to the specific needs and purposes of the investor.

3. Similarities between H beam and I beam

(1) Flange angle

The flange angles of both I and H steel profiles are 98 degrees.(2) Flange length and thickness

The flange length and thickness of these two types of steel profiles may depend on the specific model, but in general, they maintain these characteristics.

4. Differences between I beam and H beam

(1) Leg length

The legs of H steel profiles are usually longer than those of I steel profiles.(2) Web thickness

The web part of H steel profiles is usually thicker than that of I steel profiles, which helps it better withstand pressure. Conversely, the web of I steel profiles is usually thinner, reducing weight but also reducing the ability to withstand pressure.(3) Mass

Due to the thicker web part, H steel profiles are generally heavier, while I steel profiles are usually lighter because of their thinner and more compact design.(4) Engineering applications

H steel profiles are usually chosen when strong lateral load-bearing capacity is required, while I steel profiles are suitable for projects that require a lightweight structure and no large load pressure.(5) Manufacturing and dimensions

H steel profiles come in a variety of different sizes and shapes, while I steel profiles have certain limitations in production dimensions.(6) Structure

The upper and lower flanges of H steel profiles are relatively far apart, while those of I steel profiles are relatively close.These differences not only affect the choice between I and H steel profiles but also determine the efficiency and safety of construction projects.

5. Applications of I and H steel profiles in the construction industry

H steel profiles have significant lateral load-bearing capacity and are generally favored in many projects, from residential buildings, prefabricated structures to high-rise buildings and large bridges. This is due to their greater ability to withstand pressure than I steel profiles, making them the preferred choice in situations that require high load-bearing capacity.At the same time, I steel profiles also have a wide range of applications, similar to H steel profiles, used in various projects from residential buildings, prefabricated structures to high-rise buildings and bridges. However, due to their lightweight design, I steel profiles are usually considered first in projects that require a lightweight structure and no large load pressure.

The choice between I and H steel profiles usually depends on the specific requirements of each project, thus determining which type of steel profile is more suitable to ensure efficiency and safety during use.

6. Cost of I and H steel profiles

Due to their greater weight and structure, the price of H steel profiles is usually higher than that of I steel profiles. This leads to the average consumption of H steel profiles in the market being greater than that of I steel profiles.The price difference between these two types of steel profiles depends on many factors, including specific dimensions, quality, and market conditions. However, for the same quality, characteristics, and equal mass of a certain quality, the price of H steel profiles is usually higher because their raw materials and production requirements are more complex.