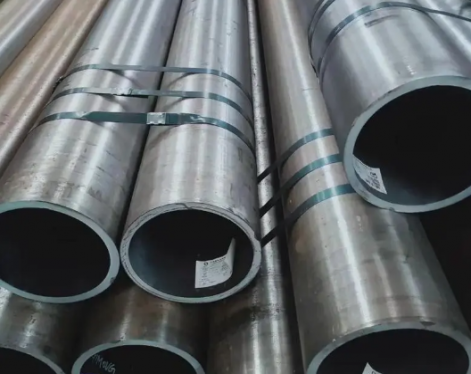

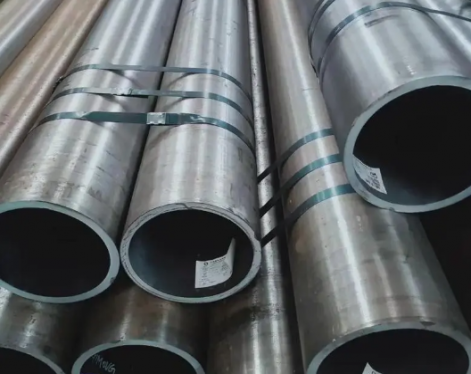

What is boiler tube?

Boiler tubes are a type of steel tube. Boiler tubes are generally made of seamless steel pipes, so boiler tubes are also seamless tubes. However, due to the requirements of the use environment of boiler tubes, the selection of materials is relatively strict. Commonly used materials include carbon steel, alloy steel, stainless steel, etc.

According to the different operating temperatures of boiler tubes, they are divided into general boiler tubes and high-pressure boiler tubes.

Generally, the operating temperature of boiler tubes is below 450°C, and they are mainly made of hot-rolled or cold-drawn tubes of No. 10 and No. 20 ordinary carbon steel.

The operating temperature of high-pressure boiler tubes is between 450°C and 650°C. High-pressure boiler tubes are often exposed to high temperature and high pressure conditions when used. Under the action of high-temperature flue gas and water vapor, the tubes will oxidize and corrode. It is mainly made of 20G, 12Cr1MoVG, 40Cr and other materials with high durability, strong corrosion and oxidation resistance, and high organizational stability.

How to install boiler tubes?

The installation methods of boiler tubes mainly include stacking installation and pipe connection installation.

1. Stacking installation

The so-called stacking installation refers to directly stacking boiler tubes with bricks or other materials to form a fixed structure. The specific steps are as follows:

a. Determine the stacking structure and size based on the size and shape of the boiler tubes.

b. First, lay a layer of bricks or stones on the floor or wall as a foundation to ensure it is flat and firm.

c. Build masonry on the foundation, place the bricks in sequence, and use high-temperature-resistant refractory materials to bond them. Ensure that the masonry structure is stable while leaving necessary interfaces for subsequent pipe connections.

d. Apply temperature-resistant and fire-resistant materials to the stacked boiler tubes to prevent heat conduction and air leakage.

2. Pipe connection installation

In addition to stacking installation, piping connections are also required to ensure the normal operation of the boiler. The specific steps are as follows:

a. First, design a reasonable pipeline layout based on the outlet and inlet locations of the boiler tubes. Consider factors such as safety, stability and ease of maintenance.

b. Install the pipe supports according to the layout design. The bracket must be strong and reliable and able to bear the weight of the pipe.

c. According to the design requirements, cut and process the outlet and inlet of the boiler tube to ensure the tightness of the connection with the pipe.

d. Use appropriate pipe materials (such as carbon steel pipes, stainless steel pipes, etc.) to connect pipes. The connection methods mainly include welding, threaded connection, flange connection, etc., and must be operated in accordance with relevant standards and technical requirements.

e. Perform sealing treatment and use sealant or other sealing materials to fill the interface to ensure that there will be no air or water leakage at the connection.

f. After installing the pipes, inspect and test them to ensure that the connections are firm and leak-free, and make necessary adjustments and trimmings.

In short, the installation method of boiler tubes needs to be carried out in strict accordance with relevant specifications and requirements to ensure the normal operation and safety of the boiler. At the same time, the appropriate installation method should be selected according to the specific situation.

Boiler tube uses:

Generally, boiler tubes are mainly used to make water-cooled wall tubes, boiling water tubes, superheated steam tubes, superheated steam tubes for locomotive boilers, large and small smoke tubes and arch brick tubes, etc. High-pressure boiler tubes are mainly used to make high-pressure and ultra-high-pressure boilers. Superheater tubes, reheater tubes, air guide tubes, main steam tubes, etc.

Read more: Seamless Mechanical Tubing

Boiler tubes are a type of steel tube. Boiler tubes are generally made of seamless steel pipes, so boiler tubes are also seamless tubes. However, due to the requirements of the use environment of boiler tubes, the selection of materials is relatively strict. Commonly used materials include carbon steel, alloy steel, stainless steel, etc.

According to the different operating temperatures of boiler tubes, they are divided into general boiler tubes and high-pressure boiler tubes.

Generally, the operating temperature of boiler tubes is below 450°C, and they are mainly made of hot-rolled or cold-drawn tubes of No. 10 and No. 20 ordinary carbon steel.

The operating temperature of high-pressure boiler tubes is between 450°C and 650°C. High-pressure boiler tubes are often exposed to high temperature and high pressure conditions when used. Under the action of high-temperature flue gas and water vapor, the tubes will oxidize and corrode. It is mainly made of 20G, 12Cr1MoVG, 40Cr and other materials with high durability, strong corrosion and oxidation resistance, and high organizational stability.

How to install boiler tubes?

The installation methods of boiler tubes mainly include stacking installation and pipe connection installation.

1. Stacking installation

The so-called stacking installation refers to directly stacking boiler tubes with bricks or other materials to form a fixed structure. The specific steps are as follows:

a. Determine the stacking structure and size based on the size and shape of the boiler tubes.

b. First, lay a layer of bricks or stones on the floor or wall as a foundation to ensure it is flat and firm.

c. Build masonry on the foundation, place the bricks in sequence, and use high-temperature-resistant refractory materials to bond them. Ensure that the masonry structure is stable while leaving necessary interfaces for subsequent pipe connections.

d. Apply temperature-resistant and fire-resistant materials to the stacked boiler tubes to prevent heat conduction and air leakage.

2. Pipe connection installation

In addition to stacking installation, piping connections are also required to ensure the normal operation of the boiler. The specific steps are as follows:

a. First, design a reasonable pipeline layout based on the outlet and inlet locations of the boiler tubes. Consider factors such as safety, stability and ease of maintenance.

b. Install the pipe supports according to the layout design. The bracket must be strong and reliable and able to bear the weight of the pipe.

c. According to the design requirements, cut and process the outlet and inlet of the boiler tube to ensure the tightness of the connection with the pipe.

d. Use appropriate pipe materials (such as carbon steel pipes, stainless steel pipes, etc.) to connect pipes. The connection methods mainly include welding, threaded connection, flange connection, etc., and must be operated in accordance with relevant standards and technical requirements.

e. Perform sealing treatment and use sealant or other sealing materials to fill the interface to ensure that there will be no air or water leakage at the connection.

f. After installing the pipes, inspect and test them to ensure that the connections are firm and leak-free, and make necessary adjustments and trimmings.

In short, the installation method of boiler tubes needs to be carried out in strict accordance with relevant specifications and requirements to ensure the normal operation and safety of the boiler. At the same time, the appropriate installation method should be selected according to the specific situation.

Boiler tube uses:

Generally, boiler tubes are mainly used to make water-cooled wall tubes, boiling water tubes, superheated steam tubes, superheated steam tubes for locomotive boilers, large and small smoke tubes and arch brick tubes, etc. High-pressure boiler tubes are mainly used to make high-pressure and ultra-high-pressure boilers. Superheater tubes, reheater tubes, air guide tubes, main steam tubes, etc.

Read more: Seamless Mechanical Tubing