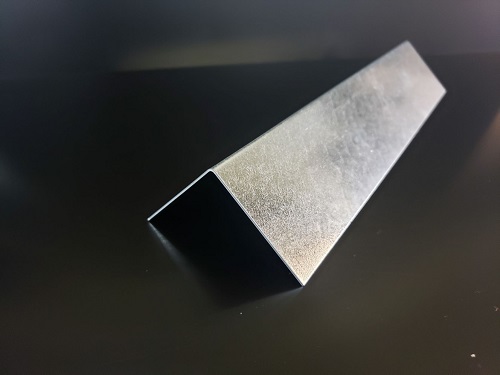

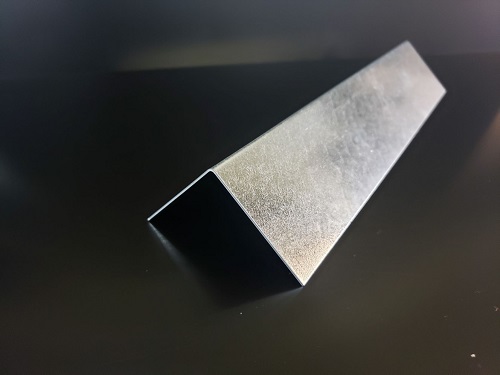

Angle steel is a type of L shaped section material, but controlling the bite and deformation in the die is not easy. Under the conditions of tandem rolling production, the leg thickness and length of the angle steel are affected by the rolling relationship between the previous and next passes, leading to various quality issues in the angle steel products, such as uneven lengths on both sides, leg edge warping, surface roughness, shearing deformation, bending, and unstable packaging, etc. Technical personnel have analyzed and solved these problems one by one.

This article introduces the instruments for measuring the length of angle steel, the principles of measurement, and other inspection items that angle steel should undergo.

The causes include: the incoming material from the front is too small, the rolling piece is not correctly bitten in the die, the stability during the rolling process is poor, and it is not guaranteed that the precision rolling, especially the butterfly hole before the finished product, is well filled, which is prone to fluctuations in leg length dimensions.

The photoelectric measurement product uses an object-side telecentric optical path and CCD imaging method for online size detection.

The core component for detecting the length of the angle steel is the photoelectric measuring head, each group of which consists of an emission lens and a receiving lens.

The light emitted by the point light source inside the emission lens forms a parallel light field through the emission lens and is directed towards the receiving lens.

The parallel light is then focused by the receiving lens and imaged on the receiving unit through a small aperture located at the focal point.

When an object passes through the field of view, the part of the object that is blocked will present a clear boundary shadow on the chip of the receiving unit.

Through photoelectric conversion and digital processing, the edge length of the measured object can be calculated through the width of the shadow.

By analyzing the components in the angle steel, its material and quality can be determined. Common component analysis methods include spectral analysis, chemical analysis, etc. Spectral analysis can determine the content of elements in the angle steel by reading the element emission and absorption spectral lines on the surface of the angle steel.

(2) Surface Inspection

Surface inspection is the detection of whether there are harmful defects, cracks, pores, etc., on the surface of the angle steel. Common methods include visual inspection, magnetic particle flaw detection, ultrasonic flaw detection, etc. Among them, magnetic particle flaw detection uses the interaction between the magnetic field and the defects in the material to produce a magnetic powder adsorption phenomenon for detecting cracks and other defects on the surface of the angle steel.

(3) Strength Testing

The strength of the angle steel is one of the important indicators of its safety in use. Common strength testing methods include tensile tests, compression tests, bending tests, etc. The tensile test is to test the tensile strength, yield strength, etc., of the angle steel by applying tensile force.

(4) Chemical Corrosion Testing

Angle steel is often exposed to harsh environments and is prone to chemical corrosion. Chemical corrosion testing can be done by applying a certain concentration of corrosive liquid on the surface of the angle steel and observing the degree of corrosion on the surface of the angle steel after a certain period to uate its corrosion resistance.

In summary, angle steel testing involves measurement methods for size, composition, surface, strength, and chemical corrosion, etc. These tests can ensure the quality of the angle steel products to meet relevant standards and requirements.

This article introduces the instruments for measuring the length of angle steel, the principles of measurement, and other inspection items that angle steel should undergo.

1. Issue of Uneven Lengths on Both Sides

The uneven lengths on both legs of the angle steel cause a significant scalene phenomenon, with one leg length at the upper limit and the other at the lower limit, and some points on the leg length have excessive deviations, which affect the positioning of drilling and welding when used in user processing.The causes include: the incoming material from the front is too small, the rolling piece is not correctly bitten in the die, the stability during the rolling process is poor, and it is not guaranteed that the precision rolling, especially the butterfly hole before the finished product, is well filled, which is prone to fluctuations in leg length dimensions.

2. Measurement Principle

The photoelectric measurement product uses an object-side telecentric optical path and CCD imaging method for online size detection.The core component for detecting the length of the angle steel is the photoelectric measuring head, each group of which consists of an emission lens and a receiving lens.

The light emitted by the point light source inside the emission lens forms a parallel light field through the emission lens and is directed towards the receiving lens.

The parallel light is then focused by the receiving lens and imaged on the receiving unit through a small aperture located at the focal point.

When an object passes through the field of view, the part of the object that is blocked will present a clear boundary shadow on the chip of the receiving unit.

Through photoelectric conversion and digital processing, the edge length of the measured object can be calculated through the width of the shadow.

3. Other Measurement Items for Angle Steel

(1) Component AnalysisBy analyzing the components in the angle steel, its material and quality can be determined. Common component analysis methods include spectral analysis, chemical analysis, etc. Spectral analysis can determine the content of elements in the angle steel by reading the element emission and absorption spectral lines on the surface of the angle steel.

(2) Surface Inspection

Surface inspection is the detection of whether there are harmful defects, cracks, pores, etc., on the surface of the angle steel. Common methods include visual inspection, magnetic particle flaw detection, ultrasonic flaw detection, etc. Among them, magnetic particle flaw detection uses the interaction between the magnetic field and the defects in the material to produce a magnetic powder adsorption phenomenon for detecting cracks and other defects on the surface of the angle steel.

(3) Strength Testing

The strength of the angle steel is one of the important indicators of its safety in use. Common strength testing methods include tensile tests, compression tests, bending tests, etc. The tensile test is to test the tensile strength, yield strength, etc., of the angle steel by applying tensile force.

(4) Chemical Corrosion Testing

Angle steel is often exposed to harsh environments and is prone to chemical corrosion. Chemical corrosion testing can be done by applying a certain concentration of corrosive liquid on the surface of the angle steel and observing the degree of corrosion on the surface of the angle steel after a certain period to uate its corrosion resistance.

In summary, angle steel testing involves measurement methods for size, composition, surface, strength, and chemical corrosion, etc. These tests can ensure the quality of the angle steel products to meet relevant standards and requirements.