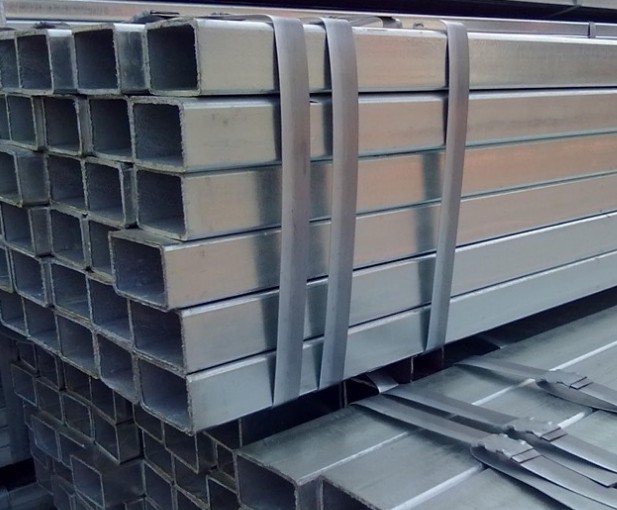

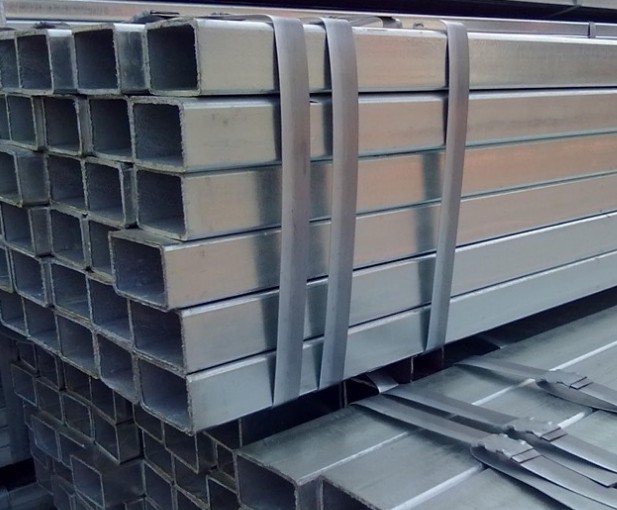

The galvanized square tube is a hollow steel tube with a square cross-section shape and size made of hot-rolled or cold-rolled galvanized strip steel or galvanized coil as a blank, which is formed by cold bending and then high-frequency welding. Or a galvanized steel pipe made by hot-dip galvanizing the pre-made square tube. The application range of galvanized square tube has been greatly expanded compared with square tube. It is mainly used in curtain walls, construction, machinery manufacturing, steel construction projects, shipbuilding, solar power generation brackets, steel structure engineering, power engineering, power plants, agricultural and chemical machinery, glass curtain walls, automobile chassis, airports, etc.

Heat treatment of galvanized square tube

1. Before heat treatment, galvanized square pipes and fixtures should remove oil, residual salt, paint and other foreign objects;

2. The fixtures used in the vacuum furnace should be degassed and purified in advance at a vacuum degree not lower than that required by the workpiece;

3. During the heat treatment process, the deformable workpiece should be heated on a special fixture. The methods of preheating are as follows: the first preheating is 800°C, the second preheating is 500-550°C and 850°C, and the temperature rising speed of the first preheating should be limited;

4. Preheating should be carried out for workpieces with complex shapes or sharp changes in cross-section and large effective thickness;

5. Workpieces with grooves and no holes, castings and weldments, and processed stainless steel workpieces are generally not suitable for heating in a salt bath furnace;

6.the heating of galvanized square tubes should have sufficient holding time, which can be based on the effective thickness and conditional thickness of the workpiece (the actual thickness multiplied by the shape factor of the workpiece);

7. Martensitic stainless steel and heat-resistant steel galvanized square tubes can be cleaned, cryogenically treated or tempered after quenching and cooling to room temperature. The time interval between welding and subsequent heat treatment should not exceed 4 hours;

8. According to the requirements of the galvanized square pipe and the surface condition, use alkali washing, water-soluble cleaning agent, chlorine solvent sandblasting, shot blasting and other methods to clean;

9. After rectification, stress-relief annealing should be carried out at a temperature lower than the original tempering temperature. For workpieces with complex shapes or strict size requirements, after rectification, use a shaping fixture combined with tempering for rectification during tempering;

10. When the mechanical properties of the galvanized square tube are unqualified, the heat treatment can be repeated, but the number of repeated quenching or solid solution generally does not exceed two times. Supplementary tempering of galvanized square tubes does not count as retreatment. Martensitic stainless steel and heat-resistant steel workpieces in the quenched state or after low-temperature tempering should be preheated, annealed or high-temperature tempered before repeated quenching.

Heat treatment of galvanized square tube

1. Before heat treatment, galvanized square pipes and fixtures should remove oil, residual salt, paint and other foreign objects;

2. The fixtures used in the vacuum furnace should be degassed and purified in advance at a vacuum degree not lower than that required by the workpiece;

3. During the heat treatment process, the deformable workpiece should be heated on a special fixture. The methods of preheating are as follows: the first preheating is 800°C, the second preheating is 500-550°C and 850°C, and the temperature rising speed of the first preheating should be limited;

4. Preheating should be carried out for workpieces with complex shapes or sharp changes in cross-section and large effective thickness;

5. Workpieces with grooves and no holes, castings and weldments, and processed stainless steel workpieces are generally not suitable for heating in a salt bath furnace;

6.the heating of galvanized square tubes should have sufficient holding time, which can be based on the effective thickness and conditional thickness of the workpiece (the actual thickness multiplied by the shape factor of the workpiece);

7. Martensitic stainless steel and heat-resistant steel galvanized square tubes can be cleaned, cryogenically treated or tempered after quenching and cooling to room temperature. The time interval between welding and subsequent heat treatment should not exceed 4 hours;

8. According to the requirements of the galvanized square pipe and the surface condition, use alkali washing, water-soluble cleaning agent, chlorine solvent sandblasting, shot blasting and other methods to clean;

9. After rectification, stress-relief annealing should be carried out at a temperature lower than the original tempering temperature. For workpieces with complex shapes or strict size requirements, after rectification, use a shaping fixture combined with tempering for rectification during tempering;

10. When the mechanical properties of the galvanized square tube are unqualified, the heat treatment can be repeated, but the number of repeated quenching or solid solution generally does not exceed two times. Supplementary tempering of galvanized square tubes does not count as retreatment. Martensitic stainless steel and heat-resistant steel workpieces in the quenched state or after low-temperature tempering should be preheated, annealed or high-temperature tempered before repeated quenching.