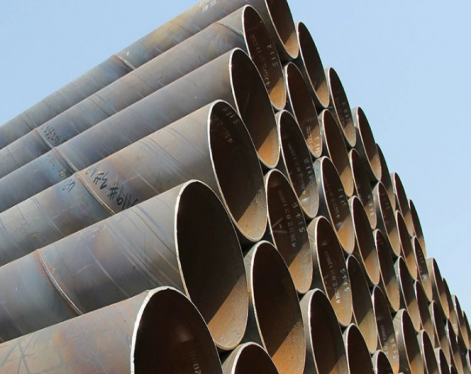

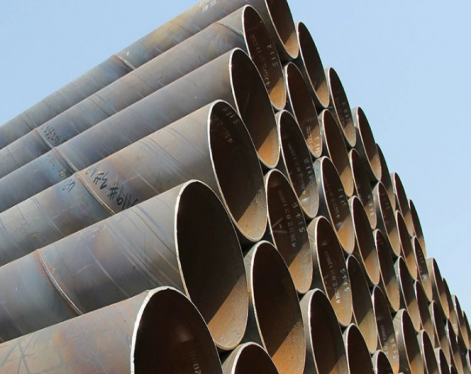

Material of piling pipe:

Currently, the commonly used materials for piling pipes include ordinary carbon structural steel, low alloy high strength steel, stainless steel and composite materials.

1. Ordinary carbon structural steel

Ordinary carbon structural steel is one of the most commonly used materials for making piles. It has the characteristics of low cost, high strength, good plasticity and good processing performance. However, it has poor corrosion resistance and is easily affected by wear and oxidation.

2. Low alloy high strength steel

Low alloy high strength steel is usually used to produce special specifications of piles such as large diameter and super long piles. It has the characteristics of high strength, good corrosion resistance and excellent compressive performance. Due to high quality and cost requirements, it is rarely used in general projects.

3. Stainless steel

Stainless steel has excellent corrosion resistance and can completely replace traditional steel for the production of piles and other equipment. Common stainless steel materials include 304, 316, 316L, etc., among which 316L is the most commonly used.

4. Composite materials

Composite materials are lightweight, high-strength, highly wear-resistant, corrosion-resistant, heat-resistant, and well-insulated, making them very suitable for producing long-life, high-quality, and high-strength pipe piles. Common composite materials include carbon fiber composite materials, glass fiber composite materials, polyamide composite materials, and the like.

The role of piling pipe:

1. Increase the bearing capacity of the foundation

Driving into deep loose soil or rock can effectively increase the bearing capacity of the foundation, so that the foundation of the building has good drainage and is not prone to settlement, cracks, and other problems.

2. Improve the poor geological environment of the foundation

Pipe piles can effectively deal with the problem of poor geological environment of the foundation. For example, pipe piles can drive deep reinforced concrete piles into the soft soil layer to ensure the safety and reliability of the foundation.

3. Stabilize the soil layer

Pipe piles can also be used to stabilize the soil layer. For example, for soil layers that need to be reinforced, such as riverbeds, after driving steel pipe piles, the soil layer will be compacted, greatly increasing the stability of the soil layer.

4. Reinforce soil-rock mixtures, etc.

Pipe piles can also be used to reinforce soil-rock mixtures. For example, in areas flooded by water and soil infiltration, the use of pipe pile construction technology can strengthen the ground soil layer while ensuring the stability of the foundation, ensuring the stability of the ground.

Application fields of piling pipe:

Piling pipe is a common foundation engineering construction technology currently widely used in the fields of construction, transportation, water conservancy, etc. Among them, the construction field is mainly used in the foundations of structures such as high-rise buildings, bridges, docks, piers, large factories, and water treatment stations. The transportation field is mainly used for the foundations of roads, bridges, urban rail transit and highways, while the water conservancy field is mainly used for dams, flood control projects and hydropower generation infrastructure construction.

Summary:

Piling pipe, as a common foundation engineering construction technology, has a wide range of applications and functions. The material selection of pile driving pipe depends on the specific engineering requirements. Carbon steel pipes are widely used due to their good cost performance and applicability, while alloy steel pipes are used in environments with special requirements, and stainless steel pipes are used in environments that require corrosion resistance. In the fields of construction, transportation, water conservancy, etc., pipe pile driving plays an important role.

Currently, the commonly used materials for piling pipes include ordinary carbon structural steel, low alloy high strength steel, stainless steel and composite materials.

1. Ordinary carbon structural steel

Ordinary carbon structural steel is one of the most commonly used materials for making piles. It has the characteristics of low cost, high strength, good plasticity and good processing performance. However, it has poor corrosion resistance and is easily affected by wear and oxidation.

2. Low alloy high strength steel

Low alloy high strength steel is usually used to produce special specifications of piles such as large diameter and super long piles. It has the characteristics of high strength, good corrosion resistance and excellent compressive performance. Due to high quality and cost requirements, it is rarely used in general projects.

3. Stainless steel

Stainless steel has excellent corrosion resistance and can completely replace traditional steel for the production of piles and other equipment. Common stainless steel materials include 304, 316, 316L, etc., among which 316L is the most commonly used.

4. Composite materials

Composite materials are lightweight, high-strength, highly wear-resistant, corrosion-resistant, heat-resistant, and well-insulated, making them very suitable for producing long-life, high-quality, and high-strength pipe piles. Common composite materials include carbon fiber composite materials, glass fiber composite materials, polyamide composite materials, and the like.

The role of piling pipe:

1. Increase the bearing capacity of the foundation

Driving into deep loose soil or rock can effectively increase the bearing capacity of the foundation, so that the foundation of the building has good drainage and is not prone to settlement, cracks, and other problems.

2. Improve the poor geological environment of the foundation

Pipe piles can effectively deal with the problem of poor geological environment of the foundation. For example, pipe piles can drive deep reinforced concrete piles into the soft soil layer to ensure the safety and reliability of the foundation.

3. Stabilize the soil layer

Pipe piles can also be used to stabilize the soil layer. For example, for soil layers that need to be reinforced, such as riverbeds, after driving steel pipe piles, the soil layer will be compacted, greatly increasing the stability of the soil layer.

4. Reinforce soil-rock mixtures, etc.

Pipe piles can also be used to reinforce soil-rock mixtures. For example, in areas flooded by water and soil infiltration, the use of pipe pile construction technology can strengthen the ground soil layer while ensuring the stability of the foundation, ensuring the stability of the ground.

Application fields of piling pipe:

Piling pipe is a common foundation engineering construction technology currently widely used in the fields of construction, transportation, water conservancy, etc. Among them, the construction field is mainly used in the foundations of structures such as high-rise buildings, bridges, docks, piers, large factories, and water treatment stations. The transportation field is mainly used for the foundations of roads, bridges, urban rail transit and highways, while the water conservancy field is mainly used for dams, flood control projects and hydropower generation infrastructure construction.

Summary:

Piling pipe, as a common foundation engineering construction technology, has a wide range of applications and functions. The material selection of pile driving pipe depends on the specific engineering requirements. Carbon steel pipes are widely used due to their good cost performance and applicability, while alloy steel pipes are used in environments with special requirements, and stainless steel pipes are used in environments that require corrosion resistance. In the fields of construction, transportation, water conservancy, etc., pipe pile driving plays an important role.