Section steel is a strip of steel with a certain cross-sectional shape and size. According to the cross-section shape, steel sections are divided into simple cross-section steel and complex cross-section steel (special-shaped steel). The former refers to square steel, round steel, flat steel, angle steel, hexagonal steel, etc.; the latter refers to I-beam, channel steel, rail, window frame steel, curved steel, etc. This article will discuss the characteristics of the four types of steel decking, i beam, c beam and h beam.

During use, the steel decking forms a unified overall structure through concrete pouring and formwork, which can bear the self-weight of the concrete and the weight of the load-bearing components of the building load. In addition, steel decking is also widely used in construction, roads, bridges and other projects to play the role of supporting and separating layers.

Comparison between steel decking and ordinary reinforced concrete floor slab:

(1) The steel decking can be used as a permanent template for cast-in-place concrete, eliminating the process of installing and removing the template during construction;

(2) After the steel decking is installed, it can be used as a construction platform. At the same time, since there is no need to use temporary supports, it will not affect the work of the next layer of construction plane;

(3) The steel decking can be used as the bottom reinforcement of the floor slab, reducing the workload of installing the slab reinforcement;

(4) Depending on the different interface shapes of the profiled plate, the amount of steel plate concrete can be reduced by up to 30%. Reducing the self-weight of the floor can correspondingly reduce the size of beams, columns and foundations, improving the overall performance of the structure;

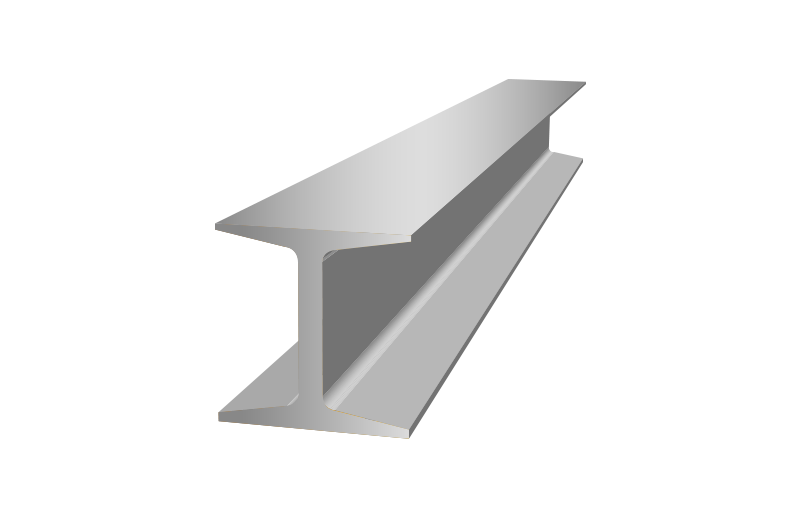

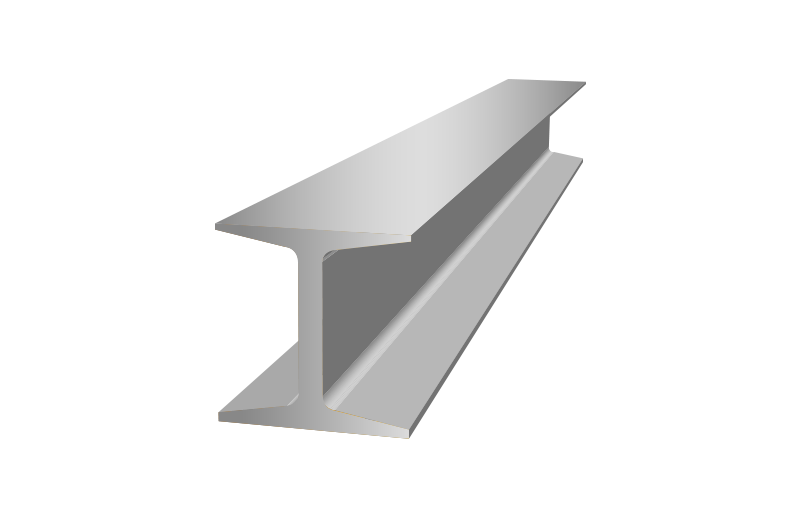

I-shaped steel is called a steel beam, which is a long steel material with an I-shaped cross-section. Its specifications are expressed in millimeters of waist height (h) * leg width (b) * waist thickness (d). For example, "Working 160*88*6" means waist height 160 mm, leg width 88 mm, and waist thickness 6 mm. Industrial steel. I-beams are divided into three types: ordinary I-beams, light I-beams and H-beams.

The flanges of ordinary I-shaped steel and light I-shaped steel gradually become thinner from the root to the edge, and have a certain angle. Because their cross-sectional dimensions are relatively high and narrow, the moment of inertia of the two main sleeves of the cross-section is quite different. Therefore, they are generally only used for members that are bent in the plane of the web or are formed into lattice-type stressed members. . It is not used for axial compression members or members that are bent perpendicular to the web plane, which has great limitations in its application range.

I-beams are widely used in various building steel structures, bridges, vehicles, supports, machinery, etc.

C-shaped steel is processed by hot coil cold bending and automatically processed by a C-shaped steel forming machine. Thin wall, light weight, excellent cross-sectional performance and high strength. Compared with traditional channel steel, the same strength can save 30% of materials.

C-shaped steel purlins are divided into five specifications according to different heights: 80, 100, 120, 140, and 160. The length can be determined according to the engineering design, but considering transportation and installation conditions, the total length generally does not exceed 12 meters.

C-shaped steel is widely used in purlins and wall beams of steel structure buildings, and can also be assembled into lightweight roof trusses, brackets and other building components. In addition, it can also be used for columns, beams and arms in mechanical light manufacturing.

H-beam is a new type of economical construction steel. H-shaped steel has an economical and reasonable cross-section shape and good mechanical properties. During rolling, the extension of each point on the cross-section is relatively uniform and the internal stress is small. Compared with ordinary I-beam steel, it has the advantages of large section modulus, light weight and metal saving, which can make buildings The structure is reduced by 30-40%; and because the inner and outer sides of the legs are parallel and the leg ends are at right angles, they can be assembled into components, which can save 25% of the welding and riveting workload. It is often used for brackets and foundation piles in large buildings with large load-bearing capacity and good cross-sectional stability.

Advantages of H-beam:

(1) The flange is wide and the lateral stiffness is large. Strong bending resistance.

(2) The two surfaces of the flange are parallel to each other, making connection, processing and installation easy.

(3) Compared with welded I-beams, it has low cost, high precision, small residual stress, and does not require expensive welding. (4) Material and weld inspection can save about 30% of steel structure production costs.

(5) Under the same cross-sectional load. Hot-rolled H steel structure is 15%-20% lighter than traditional steel structure

(6) Compared with the concrete structure, the hot-rolled H steel structure can increase the use area by 6%, while the structure's self-weight is reduced by 20% to 30%, reducing the internal stress of the structural design.

(7) H-shaped steel can be processed into T-shaped steel, and honeycomb beams can be combined to form various cross-sectional forms, which greatly meets the needs of engineering design and production.

1. Steel decking

Steel decking is a building structural material. Its main function is to support the concrete on the floor and disperse the building load to ensure the stability of the building. Steel decking is usually composed of pressed steel plates or steel trusses. This material can be used in combination with concrete to jointly bear the load and take advantage of both steel and concrete materials. The steel truss steel decking is composed of a truss connected by upper chord steel bars, lower chord steel bars and web steel bars through resistance spot welding. They are connected with the bottom formwork to form an integral combined load-bearing plate.

During use, the steel decking forms a unified overall structure through concrete pouring and formwork, which can bear the self-weight of the concrete and the weight of the load-bearing components of the building load. In addition, steel decking is also widely used in construction, roads, bridges and other projects to play the role of supporting and separating layers.

Comparison between steel decking and ordinary reinforced concrete floor slab:

(1) The steel decking can be used as a permanent template for cast-in-place concrete, eliminating the process of installing and removing the template during construction;

(2) After the steel decking is installed, it can be used as a construction platform. At the same time, since there is no need to use temporary supports, it will not affect the work of the next layer of construction plane;

(3) The steel decking can be used as the bottom reinforcement of the floor slab, reducing the workload of installing the slab reinforcement;

(4) Depending on the different interface shapes of the profiled plate, the amount of steel plate concrete can be reduced by up to 30%. Reducing the self-weight of the floor can correspondingly reduce the size of beams, columns and foundations, improving the overall performance of the structure;

2. I beam

I-shaped steel is called a steel beam, which is a long steel material with an I-shaped cross-section. Its specifications are expressed in millimeters of waist height (h) * leg width (b) * waist thickness (d). For example, "Working 160*88*6" means waist height 160 mm, leg width 88 mm, and waist thickness 6 mm. Industrial steel. I-beams are divided into three types: ordinary I-beams, light I-beams and H-beams.The flanges of ordinary I-shaped steel and light I-shaped steel gradually become thinner from the root to the edge, and have a certain angle. Because their cross-sectional dimensions are relatively high and narrow, the moment of inertia of the two main sleeves of the cross-section is quite different. Therefore, they are generally only used for members that are bent in the plane of the web or are formed into lattice-type stressed members. . It is not used for axial compression members or members that are bent perpendicular to the web plane, which has great limitations in its application range.

I-beams are widely used in various building steel structures, bridges, vehicles, supports, machinery, etc.

3.C beam

C-shaped steel is processed by hot coil cold bending and automatically processed by a C-shaped steel forming machine. Thin wall, light weight, excellent cross-sectional performance and high strength. Compared with traditional channel steel, the same strength can save 30% of materials.C-shaped steel purlins are divided into five specifications according to different heights: 80, 100, 120, 140, and 160. The length can be determined according to the engineering design, but considering transportation and installation conditions, the total length generally does not exceed 12 meters.

C-shaped steel is widely used in purlins and wall beams of steel structure buildings, and can also be assembled into lightweight roof trusses, brackets and other building components. In addition, it can also be used for columns, beams and arms in mechanical light manufacturing.

4. H-beam

H-shaped steel is an economical cross-section steel optimized and developed from I-shaped steel with better cross-section mechanical properties. It is named after the cross-section is the same as the English letter "H". H-shaped steel is divided into wide-flange steel (HW), medium-flange H-shaped steel (HM), narrow-flange H-beam steel (HN), thin-walled H-shaped steel (HT), and H-shaped steel (HU).H-beam is a new type of economical construction steel. H-shaped steel has an economical and reasonable cross-section shape and good mechanical properties. During rolling, the extension of each point on the cross-section is relatively uniform and the internal stress is small. Compared with ordinary I-beam steel, it has the advantages of large section modulus, light weight and metal saving, which can make buildings The structure is reduced by 30-40%; and because the inner and outer sides of the legs are parallel and the leg ends are at right angles, they can be assembled into components, which can save 25% of the welding and riveting workload. It is often used for brackets and foundation piles in large buildings with large load-bearing capacity and good cross-sectional stability.

Advantages of H-beam:

(1) The flange is wide and the lateral stiffness is large. Strong bending resistance.

(2) The two surfaces of the flange are parallel to each other, making connection, processing and installation easy.

(3) Compared with welded I-beams, it has low cost, high precision, small residual stress, and does not require expensive welding. (4) Material and weld inspection can save about 30% of steel structure production costs.

(5) Under the same cross-sectional load. Hot-rolled H steel structure is 15%-20% lighter than traditional steel structure

(6) Compared with the concrete structure, the hot-rolled H steel structure can increase the use area by 6%, while the structure's self-weight is reduced by 20% to 30%, reducing the internal stress of the structural design.

(7) H-shaped steel can be processed into T-shaped steel, and honeycomb beams can be combined to form various cross-sectional forms, which greatly meets the needs of engineering design and production.