1. Steel Beams: I-Beam and H-Beam

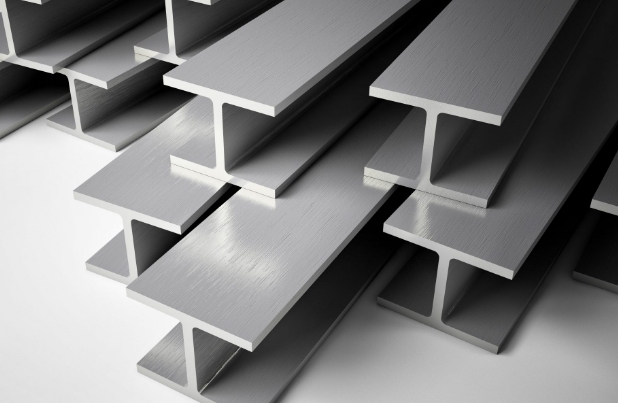

(1) Steel Beams

Steel beams are beams made of steel material. Crane beams and working platform beams in factory buildings, floor beams in multi-story buildings, and purlins in roof structures can all utilize steel beams. The two most common forms are I-beams and H-beams.

(2) I-Beam

The I-beam, which comes in standard and lightweight versions, is a type of steel with a cross-sectional shape resembling the letter "I".

Presently, there are two main types of I-beams. One type is the curved web steel, which can be obtained through cold rolling or hot rolling, and extrusion bending. The other type is the flat web beam, which can be achieved through welding or by covering with concrete.

Applications:

①Beam and column components in industrial and civil steel structure construction;

②Steel bearing brackets for industrial structures;

③Steel piles and support structures for underground engineering;

④Industrial equipment structures for petrochemical, power, and other industries;

⑤Components for long-span steel bridges;

⑥Framework structures for ships, machinery manufacturing, etc.

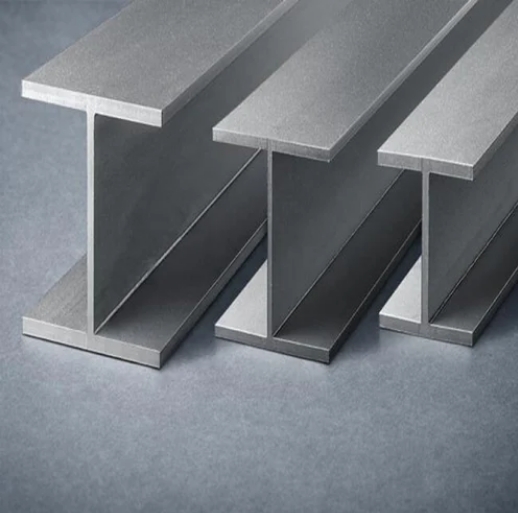

(3) H-Beam

H-beams are widely used in today's steel structure construction. Compared to I-beams, there are many differences. The first is the flange. The inner surface of the flange has no inclination, and the top and bottom surfaces are parallel. The sectional characteristics of H-beams are superior to those of traditional I-beams, channels, and angles. H-beams are an economical and efficient profile with an optimized cross-sectional area distribution and a more reasonable strength-to-weight ratio. It is named H-beam because its cross-section is the same as the English letter "H". The two outer sides of the H-beam are without inclination and are straight. This makes the welding and splicing of H-beams easier than I-beams, with better mechanical performance per unit weight, which can save a large amount of material and construction time.

2. Wood Beams: LVL Beam

Looking globally, concrete and steel have always been the preferred materials for structural construction. However, in the past decade, timber has once again become a popular building material. Wood itself is a renewable resource, and apart from being pollution-free, its natural grain and color have won the favor of many architects.

LVL is made from thick veneers that are laminated in the direction of the grain, hot-pressed with adhesive, and then sawn. It can make up for the shortcomings of artificially fast-growing timber such as soft texture, low strength, and large dimensional variability, achieving the optimal use of inferior materials and small materials on a large scale, and alleviating the contradiction brought about by wood shortages.

Principle of the process: LVL is made from thick veneers that are laminated in the direction of the grain, hot-pressed with adhesive, and then sawn. Its production process is similar to that of plywood, with the veneer preparation process being almost identical, and the main differences lie in the lamination, hot pressing, and post-treatment processes.

The unidirectional lamination and parallel hot pressing production method give LVL advantages such as uniform structure, high strength, and good dimensional stability compared to solid wood, meeting the requirements of a wide range of applications.

Due to its advantages in specifications and strength performance, LVL has a very broad application range. According to its use, it can be divided into: Structural LVL (load-bearing components): including load-bearing structural parts such as building beams and columns, and wooden structural houses; Non-structural LVL (non-load-bearing components): including furniture, stairs, doors, door and window frames, interior partitions, etc.

3. H beams vs LVL beam

Category |

Pros of Steel Beams |

Pros of Wood Beams (LVL) |

Considerations |

|---|---|---|---|

Budget |

Generally more expensive due to material and labor |

Usually less expensive |

Special handling for steel adds cost |

Installation |

Requires heavy equipment or crane |

Easier and more familiar to use |

LVL avoids shrinkage issues |

Design Goals |

Offers more design flexibility, fewer vertical supports needed |

Easier to connect components |

Steel allows for larger open spaces and long cantilevers |

Construction Schedule |

Requires lead time and coordination |

Instantly available for on-site construction |

Dimensional lumber is readily accessible |

Sustainability |

Recyclable, long lifespan, doesn't burn |

Renewable resource, but less durable |

Wood may rot or burn; steel rusts but doesn't burn |

Regional Factors |

Can be cheaper in areas with abundant steel manufacturing |

Can be cheaper in areas with abundant forests |

Prices can vary based on location |

The choice between steel beams and wood beams depends on several factors, including budget, design objectives, construction schedule, and sustainability preferences.Wood is generally less expensive and easier to construct and install on-site, but it may face issues with shrinkage and durability.Steel offers greater design flexibility and long-term durability, but it may require a higher initial cost and special handling equipment.Sustainability is an important consideration; wood is a renewable resource, while steel is a recyclable material with a longer expected lifespan.The final choice should be based on the specific needs of the project, regional characteristics, and long-term goals.