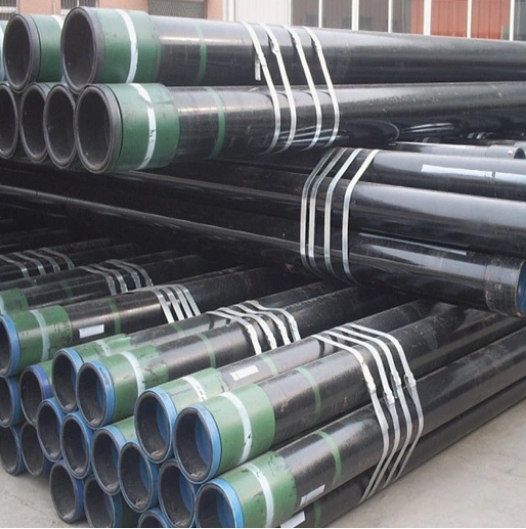

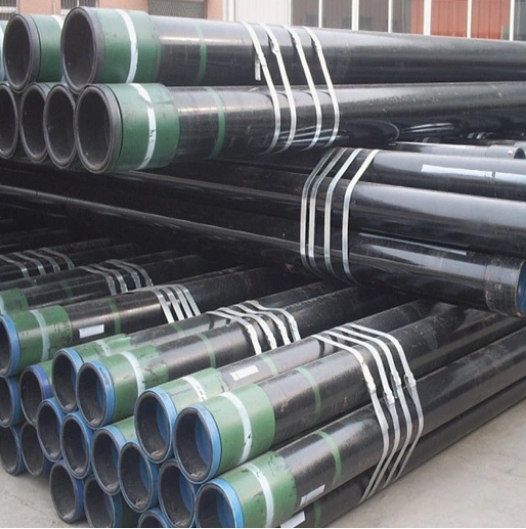

Octg casing strength refers to the ability of the octg casing material to resist damage by external forces. In petroleum engineering, octg casing is used to withstand underground pressure, prevent wellbore collapse, isolate formations and other important functions. Its strength is crucial to the stability and safe operation of the wellbore.

Casing pipe strength is closely related to the mechanical properties of the octg casing material, including yield strength, tensile strength, compressive strength and shear strength. These mechanical performance indicators can be obtained through experiments or theoretical calculations. In practical applications, the strength of the octg casing must meet a series of design requirements to ensure the safe operation of the wellbore.

1. The yield strength of octg casing

The yield strength of octg casing refers to the ability of the octg casing material to begin plastic deformation after being subjected to stress. When the octg casing is affected by external forces, if the yield strength of the material is reached, the octg casing will undergo plastic deformation and will no longer be able to fully restore its original shape. This is because the internal crystal structure of the octg casing material changes when exposed to external forces.

2. Tensile strength of octg casing

Tensile strength refers to the ability of the octg casing material to resist damage under tension. When the octg casing is stretched by an external force, the tensile strength refers to the maximum tensile force that the octg casing material can withstand when it is stretched to failure under a standard test condition. Tensile strength is one of the important indicators in octg casing design and use because the vertical portion of the wellbore is usually subjected to tensile forces caused by underground pressure.

3. Compressive strength of octg casing

Compressive strength refers to the ability of octg casing materials to resist damage when subjected to compressive force. During wellbore construction, underground pressure will exert compressive force on the octg casing wall, and the compressive strength is the maximum compressive force that the octg casing material can withstand. Compressive strength is important for wellbore stability and avoiding wellbore collapse.

4. Shear strength of steel casing pipe

Shear strength refers to the ability of octg casing materials to resist damage when subjected to shear stress. When the wellbore experiences lateral deformation, the octg casing wall will bear shear force, and shear strength is the maximum shear force that the octg casing material can withstand.

Under complex formations and high temperature and pressure conditions, the shear strength of the wellbore has become an important indicator in octg casing design. In order to ensure the reliability of octg casing strength, some safety factors are usually considered in engineering design. For example, the safety factor of octg casing strength can be increased during design to ensure the safety of octg casing under different working conditions. In addition, quality control is required during the octg casing construction process to ensure that the mechanical properties of the octg casing material meet the design requirements.

To sum up, octg casing strength refers to the ability of octg casing materials to resist damage under the action of external forces. The mechanical performance indicators such as yield strength, tensile strength, compressive strength and shear strength of the octg casing ensure the safe and stable operation of the wellbore. In engineering design, safety factors and quality control need to be considered to ensure the reliability of octg casing strength.

Casing pipe strength is closely related to the mechanical properties of the octg casing material, including yield strength, tensile strength, compressive strength and shear strength. These mechanical performance indicators can be obtained through experiments or theoretical calculations. In practical applications, the strength of the octg casing must meet a series of design requirements to ensure the safe operation of the wellbore.

1. The yield strength of octg casing

The yield strength of octg casing refers to the ability of the octg casing material to begin plastic deformation after being subjected to stress. When the octg casing is affected by external forces, if the yield strength of the material is reached, the octg casing will undergo plastic deformation and will no longer be able to fully restore its original shape. This is because the internal crystal structure of the octg casing material changes when exposed to external forces.

2. Tensile strength of octg casing

Tensile strength refers to the ability of the octg casing material to resist damage under tension. When the octg casing is stretched by an external force, the tensile strength refers to the maximum tensile force that the octg casing material can withstand when it is stretched to failure under a standard test condition. Tensile strength is one of the important indicators in octg casing design and use because the vertical portion of the wellbore is usually subjected to tensile forces caused by underground pressure.

3. Compressive strength of octg casing

Compressive strength refers to the ability of octg casing materials to resist damage when subjected to compressive force. During wellbore construction, underground pressure will exert compressive force on the octg casing wall, and the compressive strength is the maximum compressive force that the octg casing material can withstand. Compressive strength is important for wellbore stability and avoiding wellbore collapse.

4. Shear strength of steel casing pipe

Shear strength refers to the ability of octg casing materials to resist damage when subjected to shear stress. When the wellbore experiences lateral deformation, the octg casing wall will bear shear force, and shear strength is the maximum shear force that the octg casing material can withstand.

Under complex formations and high temperature and pressure conditions, the shear strength of the wellbore has become an important indicator in octg casing design. In order to ensure the reliability of octg casing strength, some safety factors are usually considered in engineering design. For example, the safety factor of octg casing strength can be increased during design to ensure the safety of octg casing under different working conditions. In addition, quality control is required during the octg casing construction process to ensure that the mechanical properties of the octg casing material meet the design requirements.

To sum up, octg casing strength refers to the ability of octg casing materials to resist damage under the action of external forces. The mechanical performance indicators such as yield strength, tensile strength, compressive strength and shear strength of the octg casing ensure the safe and stable operation of the wellbore. In engineering design, safety factors and quality control need to be considered to ensure the reliability of octg casing strength.