Steel sheet piles can be divided into: hot-rolled (stretched) steel sheet piles and cold-formed steel sheet piles according to different processing and manufacturing processes.

1. Cold-formed steel plate performs continuous cold-formed deformation on the steel strip to form a Z-shaped, U-shaped or other shape in cross-section, which can be connected to each other through the lock for building foundation plates. Steel sheet piles produced by rolling cold-formation are one of the main products of cold-formed steel in civil engineering.

2. Hot-rolled steel sheet piles are steel sheet piles produced by welding and hot rolling. Due to the advanced technology, its lock bite has tight water resistance.

According to the shape, it can be divided into: U-shaped steel sheet pile, Z-shaped steel sheet pile, L/S-shaped steel sheet pile, and linear steel sheet pile.

U-shaped steel sheet pile

1. The section width is large, which ensures that the mechanical properties of the section are fully exerted.

2. The structure is symmetrical and easy to reuse.

3. When the factory packs, it can be assembled in pairs, that is, the combined piles can be used with food, so that the quality of the product and the installation effect are better.

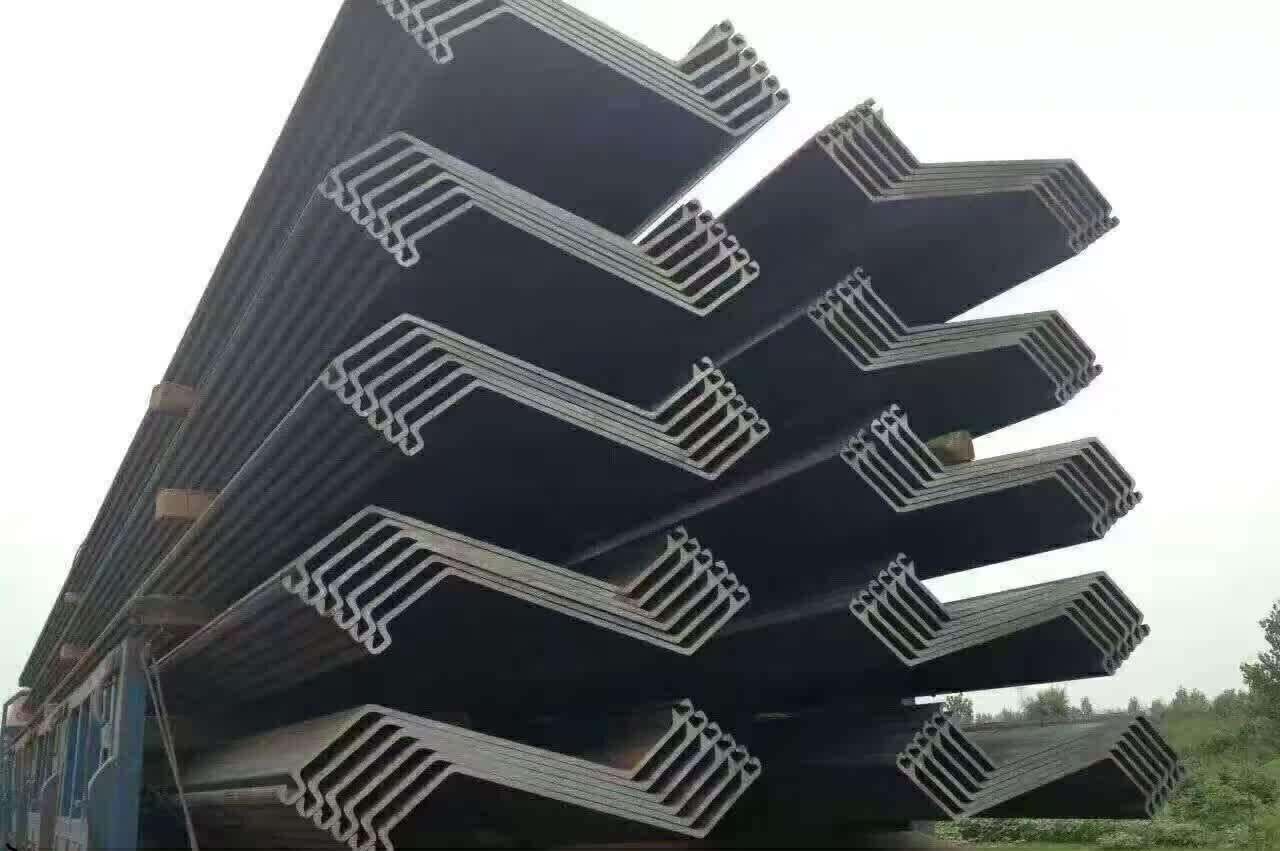

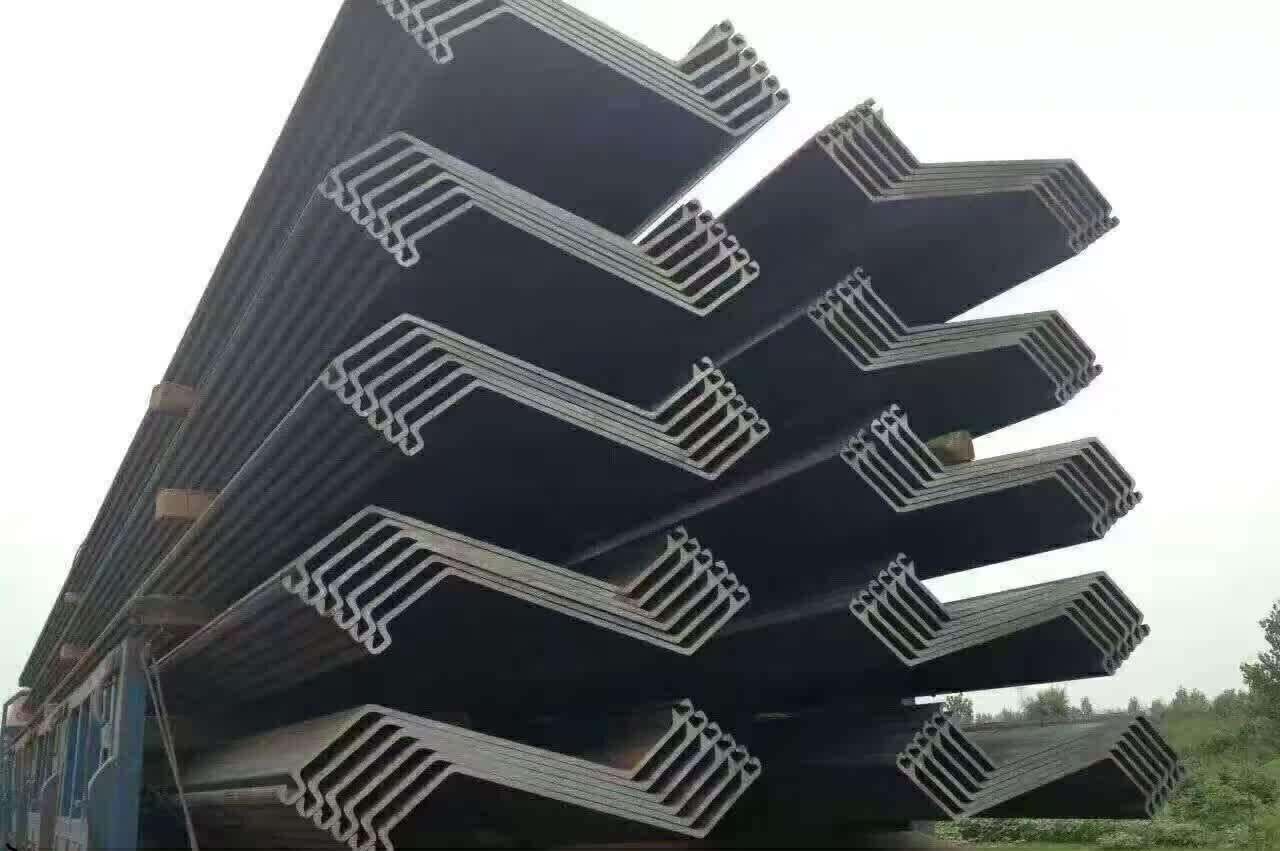

Z-type steel sheet pile

The locks of the Z-shaped steel sheet pile are distributed symmetrically on both sides of the neutral axis, and the continuity of the web increases the section modulus of the steel sheet pile to a large extent. This ensures that the mechanical properties of the section are fully utilized. Z-type steel sheet piles are widely used in automobiles, railway vehicles, shelves, electrical cabinets, highway guardrails, building steel structures, containers, transmission towers, steel sheet piles, cable bridges, agricultural machinery, furniture, vegetable greenhouses, pipe supports and other fields.

1. Characteristics of Z-type steel sheet piles

(1) The section width is large, and the pile sinking effect is remarkable

(2) section modulus punching

(3) The moment of inertia is higher, which enhances the stiffness of the steel sheet pile wall and reduces structural deformation

(4) Excellent anti-corrosion effect

2. Advantages of Z-type steel sheet piles

(1) The design is flexible and has a relatively high section modulus and mass ratio;

(2) Higher moment of inertia, which increases the stiffness of the sheet pile wall and reduces displacement deformation;

(3) The width is large, which effectively saves the time for hoisting and piling;

(4) The width of the section is increased, which reduces the number of shrinkages of the sheet pile wall and directly improves its water-tight performance;

(4) Thickening treatment is carried out on the severely corroded parts, and the corrosion resistance is more excellent.

L/S steel sheet pile

L-shape is mainly used for support of embankments, dyke walls, trenching and trenching.

The section is light, the pile wall takes up little space, and the locks are in the same direction, which is convenient for construction. It is suitable for excavation construction of municipal engineering.

Straight sheet pile

Its height is low and close to a straight line, so it is more suitable for excavating some ditches, especially when there is not much space between two buildings and it must be excavated.

1. Advantages of straight steel sheet piles

(1) It can form a stable steel sheet pile wall, so as to ensure smooth excavation downwards, without being affected by the steps on both sides and groundwater.

(2) It also helps to stabilize the foundation, thereby ensuring the stability of the buildings on both sides

1. Cold-formed steel plate performs continuous cold-formed deformation on the steel strip to form a Z-shaped, U-shaped or other shape in cross-section, which can be connected to each other through the lock for building foundation plates. Steel sheet piles produced by rolling cold-formation are one of the main products of cold-formed steel in civil engineering.

2. Hot-rolled steel sheet piles are steel sheet piles produced by welding and hot rolling. Due to the advanced technology, its lock bite has tight water resistance.

According to the shape, it can be divided into: U-shaped steel sheet pile, Z-shaped steel sheet pile, L/S-shaped steel sheet pile, and linear steel sheet pile.

U-shaped steel sheet pile

1. The section width is large, which ensures that the mechanical properties of the section are fully exerted.

2. The structure is symmetrical and easy to reuse.

3. When the factory packs, it can be assembled in pairs, that is, the combined piles can be used with food, so that the quality of the product and the installation effect are better.

Z-type steel sheet pile

The locks of the Z-shaped steel sheet pile are distributed symmetrically on both sides of the neutral axis, and the continuity of the web increases the section modulus of the steel sheet pile to a large extent. This ensures that the mechanical properties of the section are fully utilized. Z-type steel sheet piles are widely used in automobiles, railway vehicles, shelves, electrical cabinets, highway guardrails, building steel structures, containers, transmission towers, steel sheet piles, cable bridges, agricultural machinery, furniture, vegetable greenhouses, pipe supports and other fields.

1. Characteristics of Z-type steel sheet piles

(1) The section width is large, and the pile sinking effect is remarkable

(2) section modulus punching

(3) The moment of inertia is higher, which enhances the stiffness of the steel sheet pile wall and reduces structural deformation

(4) Excellent anti-corrosion effect

2. Advantages of Z-type steel sheet piles

(1) The design is flexible and has a relatively high section modulus and mass ratio;

(2) Higher moment of inertia, which increases the stiffness of the sheet pile wall and reduces displacement deformation;

(3) The width is large, which effectively saves the time for hoisting and piling;

(4) The width of the section is increased, which reduces the number of shrinkages of the sheet pile wall and directly improves its water-tight performance;

(4) Thickening treatment is carried out on the severely corroded parts, and the corrosion resistance is more excellent.

L/S steel sheet pile

L-shape is mainly used for support of embankments, dyke walls, trenching and trenching.

The section is light, the pile wall takes up little space, and the locks are in the same direction, which is convenient for construction. It is suitable for excavation construction of municipal engineering.

Straight sheet pile

Its height is low and close to a straight line, so it is more suitable for excavating some ditches, especially when there is not much space between two buildings and it must be excavated.

1. Advantages of straight steel sheet piles

(1) It can form a stable steel sheet pile wall, so as to ensure smooth excavation downwards, without being affected by the steps on both sides and groundwater.

(2) It also helps to stabilize the foundation, thereby ensuring the stability of the buildings on both sides

Previous:Features of OCTG pipes