Scope of application of carbon steel plates:

Carbon steel plates have excellent physical and mechanical properties and are high-quality structural materials. Its high hardness, good strength, and high wear resistance make it widely used in all walks of life. It is mainly used in the following aspects:

1. Construction field: It can be used to make containers, pipes, decorative panels, roofs, wall panels, stairs, etc.

2. Transportation field: It can be used to make parts for ships, cars, airplanes and other transportation tools, as well as airports, docks, highways, railway stations, etc.

3. Mechanical processing field: It can be used to make machine parts, tools, molds, etc.

4. Petrochemical field: It can be used to make oil well casings, petrochemical equipment, etc.

5. Power industry field: It can be used to make transformers, power generation equipment, electric poles, cable trays, etc.

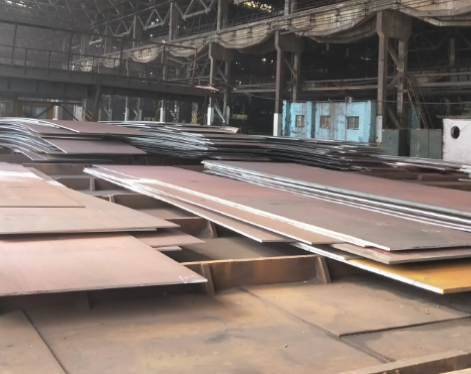

Places for laying carbon steel plates:

The places for laying carbon steel plates are also relatively wide, mainly in the following aspects:

1. Inside buildings: It can be laid in factory workshops, basements, garages, etc.

2. Building exterior: can be used for building roofs, wall panels, etc.

3. Road construction: can be used for paving roads, bridges, tunnels, parking lots and other places.

4. Transportation field: can be used in airports, docks, railway stations and other places.

5. Industrial production sites: can be used in chemical plants, metallurgical equipment, marine equipment and other fields.

Characteristics and advantages of carbon steel plates:

1. High strength and good toughness

Carbon steel plates have high strength and can withstand large pressure and tension, especially in the fields of construction, bridges, machinery and other fields. At the same time, carbon steel plates have good toughness, are not easy to deform or break when stressed, and have good plasticity and impact toughness.

2. Good processing performance

Carbon steel plates are easy to process and can be processed by cutting, bending, stamping and other methods to meet various application requirements. This makes carbon steel plates have high flexibility and efficiency in the manufacturing process.

3. Low cost

Compared with other materials, carbon steel plates have the advantages of low cost, simple production process, and easy availability, which makes carbon steel plates highly competitive in the market.

4. Wide range of applications: Carbon steel plates are widely used in construction, automobiles, machinery, pipelines and other fields.

Performance characteristics and application scenarios of different types of carbon steel plates:

1. Ordinary carbon structural steel: There are many impurities and non-metallic inclusions, it is easy to smelt, has excellent process performance and is cheap. It is mainly used for mechanical parts with low stress in construction and engineering.

2. High-quality carbon structural steel: The chemical composition is accurate and the mechanical properties are reliable. It is suitable for manufacturing stamping parts, welded structural parts and mechanical parts with low strength requirements.

3. High carbon steel: It has high strength, hardness and elasticity, but poor welding performance. It is suitable for manufacturing elastic parts such as springs and leaf springs and wear-resistant parts.

Carbon steel plates have excellent physical and mechanical properties and are high-quality structural materials. Its high hardness, good strength, and high wear resistance make it widely used in all walks of life. It is mainly used in the following aspects:

1. Construction field: It can be used to make containers, pipes, decorative panels, roofs, wall panels, stairs, etc.

2. Transportation field: It can be used to make parts for ships, cars, airplanes and other transportation tools, as well as airports, docks, highways, railway stations, etc.

3. Mechanical processing field: It can be used to make machine parts, tools, molds, etc.

4. Petrochemical field: It can be used to make oil well casings, petrochemical equipment, etc.

5. Power industry field: It can be used to make transformers, power generation equipment, electric poles, cable trays, etc.

Places for laying carbon steel plates:

The places for laying carbon steel plates are also relatively wide, mainly in the following aspects:

1. Inside buildings: It can be laid in factory workshops, basements, garages, etc.

2. Building exterior: can be used for building roofs, wall panels, etc.

3. Road construction: can be used for paving roads, bridges, tunnels, parking lots and other places.

4. Transportation field: can be used in airports, docks, railway stations and other places.

5. Industrial production sites: can be used in chemical plants, metallurgical equipment, marine equipment and other fields.

Characteristics and advantages of carbon steel plates:

1. High strength and good toughness

Carbon steel plates have high strength and can withstand large pressure and tension, especially in the fields of construction, bridges, machinery and other fields. At the same time, carbon steel plates have good toughness, are not easy to deform or break when stressed, and have good plasticity and impact toughness.

2. Good processing performance

Carbon steel plates are easy to process and can be processed by cutting, bending, stamping and other methods to meet various application requirements. This makes carbon steel plates have high flexibility and efficiency in the manufacturing process.

3. Low cost

Compared with other materials, carbon steel plates have the advantages of low cost, simple production process, and easy availability, which makes carbon steel plates highly competitive in the market.

4. Wide range of applications: Carbon steel plates are widely used in construction, automobiles, machinery, pipelines and other fields.

Performance characteristics and application scenarios of different types of carbon steel plates:

1. Ordinary carbon structural steel: There are many impurities and non-metallic inclusions, it is easy to smelt, has excellent process performance and is cheap. It is mainly used for mechanical parts with low stress in construction and engineering.

2. High-quality carbon structural steel: The chemical composition is accurate and the mechanical properties are reliable. It is suitable for manufacturing stamping parts, welded structural parts and mechanical parts with low strength requirements.

3. High carbon steel: It has high strength, hardness and elasticity, but poor welding performance. It is suitable for manufacturing elastic parts such as springs and leaf springs and wear-resistant parts.