The straight seam high frequency welded steel pipe has the characteristics of relatively simple process and fast continuous production. It has a wide range of uses in civil construction, petrochemical, light industry and other fields.

Read more

In order to avoid the fracture of the longitudinally welded steel pipe, the manufacturer of the longitudinally welded pipe usually adds alloys to the material to change its properties.

Read more

The transverse cracks in the weld are caused by the central segregation during the solidification of the continuous casting slab. After rolling, the central segregation zone is located at the edge of the high-frequency welding raw material belt. During the high-frequency welding process, the weld The upper and lower surfaces form a rougher martensite structure.

Read more

In high-frequency longitudinally welded pipes, the manifestations of cracks include long cracks, partial periodic cracks, and irregular intermittent cracks.

Read more

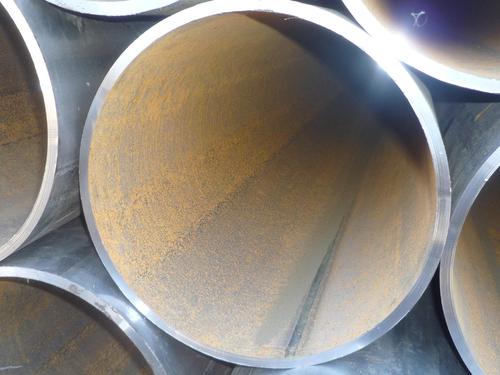

There are many things that seamless steel pipes need to be tested, especially after they leave the factory, they need to be continuously tested for all links and models of seamless steel pipes.

Read more

Steel pipes are generally divided into seamless steel pipes and welded steel pipes according to production methods. This time we mainly introduce welded steel pipes, that is, seam steel pipes.

Read more