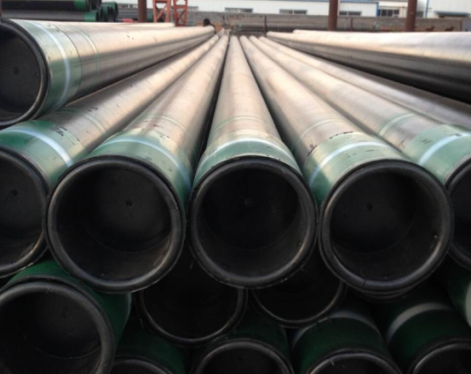

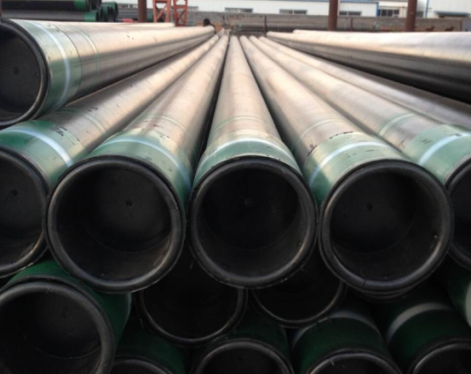

J55 casing pipe deformation may be caused by a variety of reasons, including mechanical stress during handling, improper installation, high temperature, high pressure, wear, corrosion and other factors, which can easily cause casing deformation. Here are some steps to help solve and prevent J55 casing pipe deformation.

Proper handling:

Handle J55 casing carefully to avoid excessive mechanical stress and deformation during transportation and storage. Use appropriate lifting and handling equipment to minimize the risk of bending or warping.

Storage conditions:

Store the casing in a flat horizontal position to prevent bending or sagging. If the pipe is stored vertically, ensure that it is properly supported to prevent it from deforming under its own weight.

Pre-installation inspection:

Before installation, check each casing for any signs of deformation, such as bending or warping. Do not install pipes with obvious deformation.

Proper installation techniques:

During installation, use appropriate techniques to ensure that the casing is not subjected to excessive bending or stress. Follow industry standards and guidelines for casing installation.

Controlled welding process:

If welding is involved during installation, ensure that welding parameters are controlled to prevent localized heating that could cause deformation. Proper welding techniques and procedures should be followed.

Prevent thermal deformation:

Avoid exposing the casing to extreme temperature changes as this can cause thermal deformation. If welding is required, allow the pipe to gradually cool to room temperature to minimize thermal stress.

Post-installation inspection:

After installation, inspect the casing again for any signs of deformation. Resolve any issues promptly to prevent further problems.

Use of pipe supports:

Provide adequate support for the casing at regular intervals to prevent it from sagging or bending under its own weight. This is especially important in vertical runs or areas where the pipe is not fully supported.

Avoid overloading:

Do not subject the casing to excessive loads or forces that could cause deformation. Consider the weight and pressure requirements of the specific application.

Quality assurance:

Ensure that the J55 casing used meets industry standards and quality specifications. Using high-quality materials can reduce the risk of deformation.

If deformation has already occurred, consider taking the following corrective actions:

Straightening techniques:

Depending on the degree of deformation, certain straightening techniques can be employed. However, this should be done by a professional using specialized equipment to avoid further damage.

Replacement:

If the deformation is severe, it may be necessary to replace the deformed section or the entire casing.

Proper handling:

Handle J55 casing carefully to avoid excessive mechanical stress and deformation during transportation and storage. Use appropriate lifting and handling equipment to minimize the risk of bending or warping.

Storage conditions:

Store the casing in a flat horizontal position to prevent bending or sagging. If the pipe is stored vertically, ensure that it is properly supported to prevent it from deforming under its own weight.

Pre-installation inspection:

Before installation, check each casing for any signs of deformation, such as bending or warping. Do not install pipes with obvious deformation.

Proper installation techniques:

During installation, use appropriate techniques to ensure that the casing is not subjected to excessive bending or stress. Follow industry standards and guidelines for casing installation.

Controlled welding process:

If welding is involved during installation, ensure that welding parameters are controlled to prevent localized heating that could cause deformation. Proper welding techniques and procedures should be followed.

Prevent thermal deformation:

Avoid exposing the casing to extreme temperature changes as this can cause thermal deformation. If welding is required, allow the pipe to gradually cool to room temperature to minimize thermal stress.

Post-installation inspection:

After installation, inspect the casing again for any signs of deformation. Resolve any issues promptly to prevent further problems.

Use of pipe supports:

Provide adequate support for the casing at regular intervals to prevent it from sagging or bending under its own weight. This is especially important in vertical runs or areas where the pipe is not fully supported.

Avoid overloading:

Do not subject the casing to excessive loads or forces that could cause deformation. Consider the weight and pressure requirements of the specific application.

Quality assurance:

Ensure that the J55 casing used meets industry standards and quality specifications. Using high-quality materials can reduce the risk of deformation.

If deformation has already occurred, consider taking the following corrective actions:

Straightening techniques:

Depending on the degree of deformation, certain straightening techniques can be employed. However, this should be done by a professional using specialized equipment to avoid further damage.

Replacement:

If the deformation is severe, it may be necessary to replace the deformed section or the entire casing.