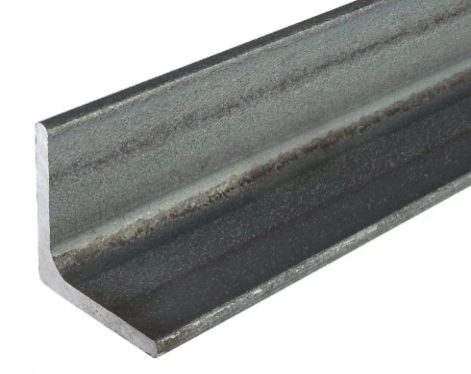

The introduction of angle steel

Angle steel, often affectionately called angle iron by everyone because of its unique L-shaped cross section, is a kind of carbon structural steel used for construction, belonging to the steel section with simple cross section. From the classification point of view, it is mainly divided into equal angle steel and unequal angle steel, among which unequal angle steel can be further divided into unequal equal thickness and unequal unequal thickness. Its specifications are expressed by the size of the side length and side thickness. The model is numbered according to the number of centimeters of the side length. The number range of equal angle steel is 2-20, and the unequal angle steel is 3.2/2-20/12.5. For the same model of angle steel, there are usually 2-7 different options for the side thickness.

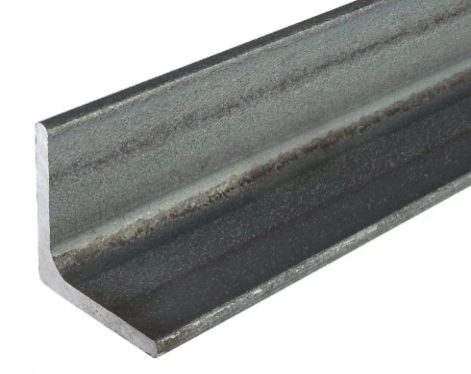

Angle steel has many advantages in use, such as good weldability, which can be easily connected with other components; good plastic deformation performance, which can be processed according to different construction requirements; and certain mechanical strength, which can effectively ensure the stability of the building structure. It is these characteristics that make it widely used in various building structures and engineering structures, such as beams, bridges, transmission towers, lifting and transportation machinery, etc.

The hazards of improper storage of angle steel

Although angle steel is strong and durable, improper storage can cause many hazards. If left in the air at will, angle steel will easily react with oxygen, oxidize and corrode, and rust will appear on the surface. Moreover, this placement method has other problems. Once it rains, the air humidity increases significantly. In a humid environment, the hardness of the angle steel will decrease, the material will become soft, and it will be easy to bend and deform.

Once the angle steel is oxidized, corroded or deformed, its mechanical strength, weldability and other properties will be greatly reduced, and it will not be able to meet the quality requirements of building structures and engineering structures, which will seriously affect its subsequent use. This will not only make it difficult to ensure the quality of the building or project, but may also require the re-purchase of angle steel, resulting in additional economic expenditures and waste of time costs, bringing unnecessary losses to enterprises and projects.

Correct storage method of angle steel

1. Choose a suitable storage site

An ideal storage site is crucial to maintaining the quality of angle steel. If there is an indoor warehouse, it should be selected with good airtightness and good sanitary conditions, which can effectively isolate humid air and dust impurities to prevent angle steel from oxidation and rust.

If it can only be stacked in the open air, the angle steel should be raised to make the stack surface slightly inclined, which is conducive to drainage and avoids water accumulation and corrosion of the angle steel; at the same time, the angle steel should be placed straight to prevent deformation due to uneven force. In addition, large-sized angle steel can be stacked in the open air, and small or easily corroded angle steel is recommended to be stored indoors or in a well-ventilated material shed.

2. Reasonable stacking

When stacking angle steel, the principle of stacking by type and specification must be strictly followed. Different types of materials should be stacked separately to prevent confusion and mutual corrosion. The same type of materials should be stacked separately according to the order of storage, so as to facilitate the implementation of the first-in-first-out principle.

3. Protective packaging and protective layer

The anti-corrosion agent or other coating and packaging applied to the angle steel by the steel mill before leaving the factory is an important line of defense to prevent the material from rusting. During transportation, loading and unloading and storage, it is important to pay attention to protection and not damage these protective measures, which can extend the storage period of the angle steel.

4. Regular inspection and maintenance

Before the angle steel is put into storage, it should be protected from rain or impurities. For materials that have been exposed to rain or soiled, different methods should be used to clean them according to their properties. After the materials are put into storage, they need to be checked frequently. Once rust is found, the rust layer should be removed in time. For general angle steel, it is not necessary to apply oil after the surface is cleaned; but for high-quality steel, alloy steel plates, thin-walled pipes, alloy steel pipes, etc., after rust removal, the inner and outer surfaces need to be coated with anti-rust oil before storage. For angle steel with severe rust, it is not suitable to be stored for a long time after rust removal, and it should be put into use as soon as possible.

Read more: What are the Advantages and Disadvantages of Angle Steel?

Angle steel, often affectionately called angle iron by everyone because of its unique L-shaped cross section, is a kind of carbon structural steel used for construction, belonging to the steel section with simple cross section. From the classification point of view, it is mainly divided into equal angle steel and unequal angle steel, among which unequal angle steel can be further divided into unequal equal thickness and unequal unequal thickness. Its specifications are expressed by the size of the side length and side thickness. The model is numbered according to the number of centimeters of the side length. The number range of equal angle steel is 2-20, and the unequal angle steel is 3.2/2-20/12.5. For the same model of angle steel, there are usually 2-7 different options for the side thickness.

Angle steel has many advantages in use, such as good weldability, which can be easily connected with other components; good plastic deformation performance, which can be processed according to different construction requirements; and certain mechanical strength, which can effectively ensure the stability of the building structure. It is these characteristics that make it widely used in various building structures and engineering structures, such as beams, bridges, transmission towers, lifting and transportation machinery, etc.

The hazards of improper storage of angle steel

Although angle steel is strong and durable, improper storage can cause many hazards. If left in the air at will, angle steel will easily react with oxygen, oxidize and corrode, and rust will appear on the surface. Moreover, this placement method has other problems. Once it rains, the air humidity increases significantly. In a humid environment, the hardness of the angle steel will decrease, the material will become soft, and it will be easy to bend and deform.

Once the angle steel is oxidized, corroded or deformed, its mechanical strength, weldability and other properties will be greatly reduced, and it will not be able to meet the quality requirements of building structures and engineering structures, which will seriously affect its subsequent use. This will not only make it difficult to ensure the quality of the building or project, but may also require the re-purchase of angle steel, resulting in additional economic expenditures and waste of time costs, bringing unnecessary losses to enterprises and projects.

Correct storage method of angle steel

1. Choose a suitable storage site

An ideal storage site is crucial to maintaining the quality of angle steel. If there is an indoor warehouse, it should be selected with good airtightness and good sanitary conditions, which can effectively isolate humid air and dust impurities to prevent angle steel from oxidation and rust.

If it can only be stacked in the open air, the angle steel should be raised to make the stack surface slightly inclined, which is conducive to drainage and avoids water accumulation and corrosion of the angle steel; at the same time, the angle steel should be placed straight to prevent deformation due to uneven force. In addition, large-sized angle steel can be stacked in the open air, and small or easily corroded angle steel is recommended to be stored indoors or in a well-ventilated material shed.

2. Reasonable stacking

When stacking angle steel, the principle of stacking by type and specification must be strictly followed. Different types of materials should be stacked separately to prevent confusion and mutual corrosion. The same type of materials should be stacked separately according to the order of storage, so as to facilitate the implementation of the first-in-first-out principle.

3. Protective packaging and protective layer

The anti-corrosion agent or other coating and packaging applied to the angle steel by the steel mill before leaving the factory is an important line of defense to prevent the material from rusting. During transportation, loading and unloading and storage, it is important to pay attention to protection and not damage these protective measures, which can extend the storage period of the angle steel.

4. Regular inspection and maintenance

Before the angle steel is put into storage, it should be protected from rain or impurities. For materials that have been exposed to rain or soiled, different methods should be used to clean them according to their properties. After the materials are put into storage, they need to be checked frequently. Once rust is found, the rust layer should be removed in time. For general angle steel, it is not necessary to apply oil after the surface is cleaned; but for high-quality steel, alloy steel plates, thin-walled pipes, alloy steel pipes, etc., after rust removal, the inner and outer surfaces need to be coated with anti-rust oil before storage. For angle steel with severe rust, it is not suitable to be stored for a long time after rust removal, and it should be put into use as soon as possible.

Read more: What are the Advantages and Disadvantages of Angle Steel?