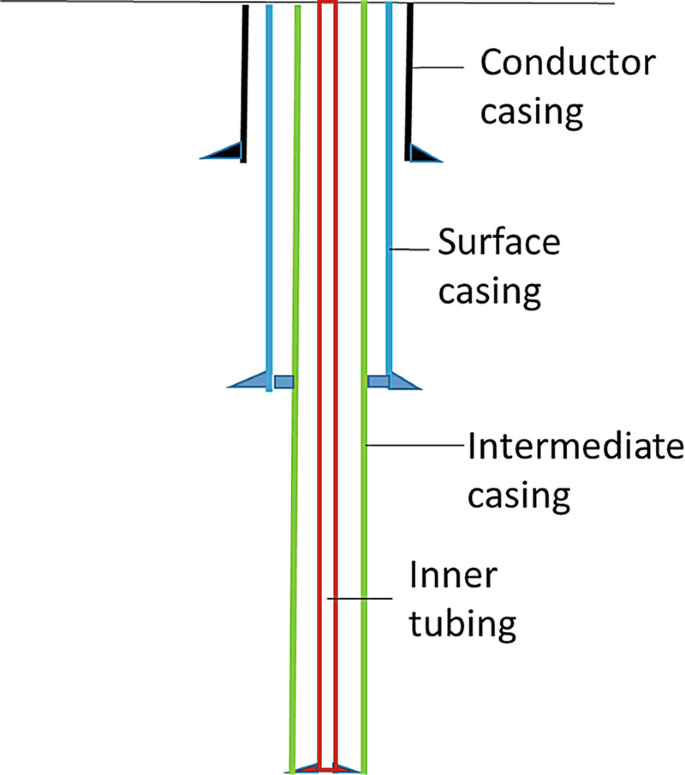

Casing is a type of OCTG pipe and plays an important role in the cementing process. Cementing is an indispensable key link in the drilling and completion process, which includes running casing and cementing. During the cementing process, the well structure mainly consists of conductor casing, surface casing, intermediate casing, production casing and cement rings outside each layer of casing. The well structure refers to a combination of a set of casings and cement sheaths with overlapping axes formed by cement injection to seal the annular space with different diameters, depths and functions.

The second layer of casing in the well structure is called surface casing, which is generally tens to hundreds of meters long. After being lowered, cement the well back to the surface with cement slurry. Its function is to isolate the upper unstable soft strata and water layers.

Intermediate casing plays an important role in drilling engineering. Its main functions include:

The calculation of intermediate casing depth is of great significance to the smooth production and safety of oil and gas wells, and can improve the recovery rate and production efficiency of oil and gas wells. This technology is widely used in oil, natural gas and other energy field.

Collect relevant data such as casing specifications, material properties, installation conditions, etc.

②Modeling

Based on the actual structure and stress conditions of the casing, a mechanical analysis model is established.

③Input parameters

Input the collected data and known conditions into the model.

④Calculation

Solve the sinking depth of the casing through numerical calculation methods

⑤Result output

Output the calculation results, including the sinking depth of the casing, stress distribution, etc.

A.Soil type

Soil type has a great influence on the depth of casing. For example, geological structures such as faults and fissures also have an impact on the bearing capacity and stability of different soils such as sand and clay deep under casing. The different geological properties need to be fully considered during design. Different depth plans need to be adopted.

B. Groundwater level

The level of the groundwater level will affect the bearing capacity of the soil, which in turn affects the depth of the casing. In areas with high groundwater levels, the casing depth needs to be appropriately increased to ensure its stability.

C.Geological structure

Geological structures such as faults and fissures also have an impact on the casing depth. The impact of geological structures on the bearing capacity of casing needs to be fully considered during design.

②Influence of casing material

A. Casing material

The material of the casing has a great influence on the depth. For example, casings made of different materials such as steel pipes and plastic pipes have different load-bearing capacities and durability. It is necessary to select the appropriate casing material according to the specific situation.

B. Casing wall thickness

The wall thickness of the casing also affects the depth. A casing with a larger wall thickness can withstand greater external force, so the depth of the casing can be appropriately reduced.

③Influence of construction conditions

A.Construction machinery

The performance and quantity of construction machinery have an impact on the efficiency and quality of casing drilling. Construction machinery with good performance can improve the accuracy and reliability of casing drilling.

B.Construction environment

The construction environment, such as weather and terrain, has a greater impact on the depth of casing. Bad weather and terrain conditions may increase the difficulty and risk of construction. Corresponding measures need to be taken to ensure construction safety and quality.

1.Types of casing pipe

(1)Conductor casing

The first layer of casing run into the well structure is called the conductor casing. Its function is to maintain the surface layer near the wellhead.(2)Surface casingThe second layer of casing in the well structure is called surface casing, which is generally tens to hundreds of meters long. After being lowered, cement the well back to the surface with cement slurry. Its function is to isolate the upper unstable soft strata and water layers.

(3)Intermediate casing

It is the casing between the surface casing and the oil layer casing. It is a seamless pipe or welded pipe used to drill down to the destination layer when it encounters complex formations such as high-pressure oil, gas and water layers, lost circulation layers, and collapse layers during drilling. Its layers are determined by the number of complex layers. The intermediate casing is run because of the technical needs of drilling, so it is also called technical casing.(4)Production casing

The oil layer casing is the innermost layer of casing in the well structure. It is also called production casing. Its depth depends on the drilling depth of the oil well and the completion method. It is generally required that the cementing cement be returned to the top of the uppermost oil and gas layer 100 to 150 meters. Its function is to isolate the oil, gas and water layers and establish a channel for long-term oil and gas extraction.

2.Intermediate casing function

Intermediate casing plays an important role in drilling engineering. Its main functions include:

(1) Preventing blowout

The middle casing is suspended on the casing head through a hanger, and the upper part can be connected to a four-way blowout preventer to effectively prevent blowout accidents.(2) Enhancing connection strength

The intermediate sleeve helps to enhance the connection strength, especially when subjected to lateral loads or vibration loads. By increasing the bearing area and dispersing the force, the connection strength is improved and the risk of bolt loosening or breaking is reduced.(3) Dispersing pressure

The intermediate sleeve helps to disperse the pressure endured by the bolt during the connection process, making the bearing capacity more balanced and reducing local pressure, thus reducing the risk of bolt brittleness.(4) Preventing corrosion

The intermediate sleeve helps prevent corrosion damage to the bolt by isolating the bolt from the connection, slowing the rate of corrosion and reducing the risk of sharp corrosives directly entering the interior of the bolt.(5) Isolating different formation pressures

The intermediate casing is used to isolate the pore pressure of different formations and prevent complex formation conditions such as easy collapse and leakage.(6) Protecting the wellbore

The intermediate casing string is used to protect the wellbore, sometimes called "protective casing" or "salt casing". It seals the fragile formation during drilling to prevent heavy mud contamination or wellbore damage.(7) Closing the old production layer

Intermediate casing strings are sometimes used to seal off old production zones so that deeper reservoirs can be drilled.(8) Preventing leakage in shallow formations

When drilling deeper wells, the intermediate casing withstands higher formation pressure and prevents lost circulation in shallow formations.3. The depth of the intermediate casing

The calculation of the depth of the intermediate casing is an important technology in petroleum engineering, which mainly involves determining the depth of the intermediate casing during the drilling process. The purpose of the calculation of the depth of the intermediate casing is to ensure that the casing can meet the production needs of the oil and gas well , while avoiding various problems caused by going too deep or too shallow.The calculation of intermediate casing depth is of great significance to the smooth production and safety of oil and gas wells, and can improve the recovery rate and production efficiency of oil and gas wells. This technology is widely used in oil, natural gas and other energy field.

(1)Calculation formula

Based on the structure and material properties of the intermediate casing and combined with mechanical principles, a formula for calculating the depth of the intermediate casing is derived. The formula includes parameters such as casing diameter, wall thickness, material elastic modulus, Poisson's ratio, etc .(2)Principle

Using mechanical principles, especially relevant knowledge of elastic mechanics and material mechanics, the deformation and stress distribution of the casing under the action of external forces are analyzed to determine the sinking depth of the casing.(3) Calculation steps and processes

①Data collectionCollect relevant data such as casing specifications, material properties, installation conditions, etc.

②Modeling

Based on the actual structure and stress conditions of the casing, a mechanical analysis model is established.

③Input parameters

Input the collected data and known conditions into the model.

④Calculation

Solve the sinking depth of the casing through numerical calculation methods

⑤Result output

Output the calculation results, including the sinking depth of the casing, stress distribution, etc.

(4)Factors affecting the depth of the intermediate casing

①Influence of geological conditionsA.Soil type

Soil type has a great influence on the depth of casing. For example, geological structures such as faults and fissures also have an impact on the bearing capacity and stability of different soils such as sand and clay deep under casing. The different geological properties need to be fully considered during design. Different depth plans need to be adopted.

B. Groundwater level

The level of the groundwater level will affect the bearing capacity of the soil, which in turn affects the depth of the casing. In areas with high groundwater levels, the casing depth needs to be appropriately increased to ensure its stability.

C.Geological structure

Geological structures such as faults and fissures also have an impact on the casing depth. The impact of geological structures on the bearing capacity of casing needs to be fully considered during design.

②Influence of casing material

A. Casing material

The material of the casing has a great influence on the depth. For example, casings made of different materials such as steel pipes and plastic pipes have different load-bearing capacities and durability. It is necessary to select the appropriate casing material according to the specific situation.

B. Casing wall thickness

The wall thickness of the casing also affects the depth. A casing with a larger wall thickness can withstand greater external force, so the depth of the casing can be appropriately reduced.

③Influence of construction conditions

A.Construction machinery

The performance and quantity of construction machinery have an impact on the efficiency and quality of casing drilling. Construction machinery with good performance can improve the accuracy and reliability of casing drilling.

B.Construction environment

The construction environment, such as weather and terrain, has a greater impact on the depth of casing. Bad weather and terrain conditions may increase the difficulty and risk of construction. Corresponding measures need to be taken to ensure construction safety and quality.

Previous:Casing drilling