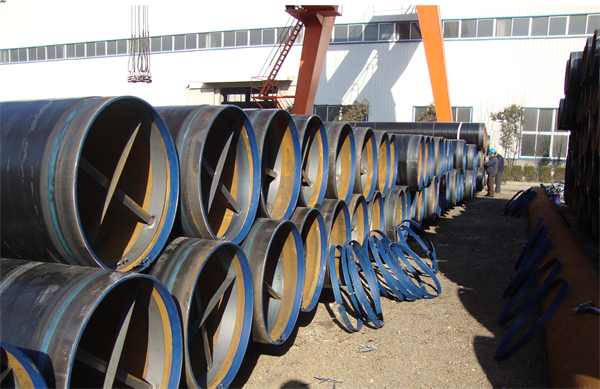

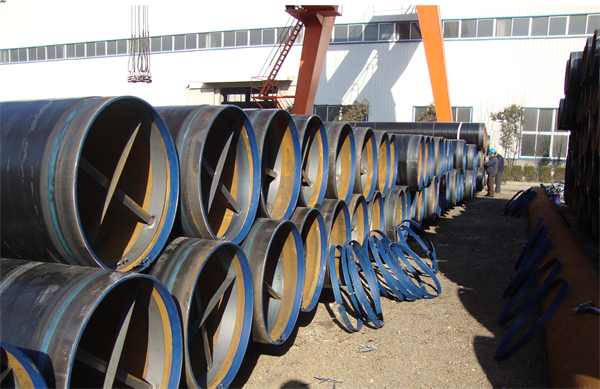

Submerged arc welded straight seam steel pipe (LSAW pipe) is a kind of steel pipe used in oil and gas pipelines with large consumption and high reliability. The forming unit forms include UOE, RBE, JCOE, etc.

JCOE forming unit equipment

1. Process equipment before forming

(1) Plate end derusting machine. When the steel plate is transported forward, the two sides of the steel plate are sprayed with a rust remover to remove the rust or oil stains on the upper and lower sides of the steel plate at about 100mm from both ends.

(2) Steel plate chamfering machine. Install the aerobic acetylene cutting nozzle, and automatically cut the edge of the board along the track for chamfering. There is a chamfering machine on each side of the steel plate placed on the workbench.

(3) Plate edge pre-bending forming machine. The upper and lower rolls are used to bend the steel plate, and the rolls are divided into front and rear sections, and the distance between the two axes is fixed. Adjust the up, down, left, and right of the roll to get a proper arc.

2. JCOE forming machine

(1) The JCOE molding machine is composed of 4 hydraulic beds, each hydraulic bed is composed of a 620mm main hydraulic cylinder, and the distance between each hydraulic cylinder is 3.2mm. The hydraulic cylinders can be operated independently or synchronously.

(2) JCOE forming machine is equipped with upper and lower molds of various shapes, which can produce steel pipes, angle steels, cold stamping parts, etc.

3. Main equipment in post-forming process

(1) The steel pipe carrying trolley consists of 2 stages. The steel pipe is placed on the carrying platform, and the two carrying platforms are pulled up by the conveying chain to move synchronously, and sent to the pre-welding machine, and the opening is rotated to align with the steel pipe being pre-welded, so that it is connected and fed continuously.

(2) Continuous pre-welding machine. Use rollers to rotate the steel pipe so that the notch faces upwards, then bundle the opening of the steel pipe into a straight line, and then use the second welder for pre-welding of the weld bead to close the opening.

(3) 2 carrying trolleys. One is used for continuous pre-welding and sent to the inner and outer welding areas of steel pipes, and the other is used for rounding and sent to the chamfering and flattening of steel pipes.

(4) Welding equipment for the inner surface of the steel pipe. After the steel pipe is hoisted into the welding machine for positioning, use a straight rod with a guide wheel at the front end to place it at the welding bead to guide the welding and keep it in a straight line. The front end of the straight rod is equipped with a welding rod pressure feeder, which presses and feeds the welding wire and flux delivery box, so that the flux falls by its own weight, and the straight rod is then transported by the trolley to slowly retreat according to the welding speed.

(5) Welding equipment outside the steel pipe. After the steel pipe is hoisted into the welding machine for positioning, a vehicle-mounted welding wire feeder and welding machine delivery tray are used. And let the welding flux fall by its own weight to protect the welding place, and the trolley moves slowly according to the welding speed.

(6) Sizing, rounding, straightening and expanding machines. The full circle is forced to compress the steel pipe through the full circle machine by the rolling force from the power transmission of the upper and lower rolls, and make the steel pipe permanently deformed under the yield point. For straightening, the steel pipe passes through the center of the upper and lower rollers as the fulcrum, about 2m away from the center, and the steel pipe is wound up to the required straightness with the oil cylinder in front of it.

After the steel pipe is formed, in order to achieve the required size roundness, the wedge method is used to expand from the inside of the pipe to the outside to achieve a certain protection rate.

When equipped with sizing, rounding and straightening machines, the first three types of equipment can be omitted.

(7) Steel pipe trimming machine. Among them, the gas cutting and trimming machine uses the expansion clamps of the front and rear two trimming machines to withstand the inner diameter of the steel pipe and then make the main shaft rotate, and the steel pipe also rotates accordingly. At this time, the gas self-persuading cutter is guided to withstand the outer diameter of the steel pipe, so that the gas cutting burner and the outer diameter of the steel pipe are kept at a certain distance, so as to avoid the cutting edge being not correct due to the difference in the distance. After the gas chamfering and cutting work is completed, use the feed wheel to make the turning tool longitudinally perform the end face trimming work, and the trimming work at both ends can be carried out at the same time. The mechanical end trimming machine uses fixtures to clamp and position the steel pipe, and the spindle chuck rotates for turning.

(8) Ultrasonic inspection equipment. Ultrasonic inspection of the weld bead is required before and after hydrostatic testing.

(9) Hydraulic testing machine. It consists of a main hydraulic cylinder and a traveling hydraulic cylinder, with a maximum load of 1200t and a maximum pressure of 25MPa. Both ends of the steel pipe are fixed by two test heads: one test head is fixed and the other test head is adjustable. The test head can be replaced according to different pipe diameters.

(10) Drying, rust removal and anti-rust coating on the inner surface of the steel pipe. After the hydrostatic test, the steel pipe cannot work immediately because of the damp temperature, that is, the inner and outer coatings must be dried and derusted. The unit adopts artificial shot blasting derusting method. In order to prevent the inner surface of the steel pipe from rusting during transportation and use, the inner surface of the steel pipe must be coated.

(11) Rust removal treatment on the outer surface of the steel pipe. When the steel pipe is rotating and moving forward on the conveyor table, the shot blasting machine blasts away the rust on the outer surface of the steel pipe. Thereafter, the steel pipes are given an anti-rust coating.

JCOE forming unit equipment

1. Process equipment before forming

(1) Plate end derusting machine. When the steel plate is transported forward, the two sides of the steel plate are sprayed with a rust remover to remove the rust or oil stains on the upper and lower sides of the steel plate at about 100mm from both ends.

(2) Steel plate chamfering machine. Install the aerobic acetylene cutting nozzle, and automatically cut the edge of the board along the track for chamfering. There is a chamfering machine on each side of the steel plate placed on the workbench.

(3) Plate edge pre-bending forming machine. The upper and lower rolls are used to bend the steel plate, and the rolls are divided into front and rear sections, and the distance between the two axes is fixed. Adjust the up, down, left, and right of the roll to get a proper arc.

2. JCOE forming machine

(1) The JCOE molding machine is composed of 4 hydraulic beds, each hydraulic bed is composed of a 620mm main hydraulic cylinder, and the distance between each hydraulic cylinder is 3.2mm. The hydraulic cylinders can be operated independently or synchronously.

(2) JCOE forming machine is equipped with upper and lower molds of various shapes, which can produce steel pipes, angle steels, cold stamping parts, etc.

3. Main equipment in post-forming process

(1) The steel pipe carrying trolley consists of 2 stages. The steel pipe is placed on the carrying platform, and the two carrying platforms are pulled up by the conveying chain to move synchronously, and sent to the pre-welding machine, and the opening is rotated to align with the steel pipe being pre-welded, so that it is connected and fed continuously.

(2) Continuous pre-welding machine. Use rollers to rotate the steel pipe so that the notch faces upwards, then bundle the opening of the steel pipe into a straight line, and then use the second welder for pre-welding of the weld bead to close the opening.

(3) 2 carrying trolleys. One is used for continuous pre-welding and sent to the inner and outer welding areas of steel pipes, and the other is used for rounding and sent to the chamfering and flattening of steel pipes.

(4) Welding equipment for the inner surface of the steel pipe. After the steel pipe is hoisted into the welding machine for positioning, use a straight rod with a guide wheel at the front end to place it at the welding bead to guide the welding and keep it in a straight line. The front end of the straight rod is equipped with a welding rod pressure feeder, which presses and feeds the welding wire and flux delivery box, so that the flux falls by its own weight, and the straight rod is then transported by the trolley to slowly retreat according to the welding speed.

(5) Welding equipment outside the steel pipe. After the steel pipe is hoisted into the welding machine for positioning, a vehicle-mounted welding wire feeder and welding machine delivery tray are used. And let the welding flux fall by its own weight to protect the welding place, and the trolley moves slowly according to the welding speed.

(6) Sizing, rounding, straightening and expanding machines. The full circle is forced to compress the steel pipe through the full circle machine by the rolling force from the power transmission of the upper and lower rolls, and make the steel pipe permanently deformed under the yield point. For straightening, the steel pipe passes through the center of the upper and lower rollers as the fulcrum, about 2m away from the center, and the steel pipe is wound up to the required straightness with the oil cylinder in front of it.

After the steel pipe is formed, in order to achieve the required size roundness, the wedge method is used to expand from the inside of the pipe to the outside to achieve a certain protection rate.

When equipped with sizing, rounding and straightening machines, the first three types of equipment can be omitted.

(7) Steel pipe trimming machine. Among them, the gas cutting and trimming machine uses the expansion clamps of the front and rear two trimming machines to withstand the inner diameter of the steel pipe and then make the main shaft rotate, and the steel pipe also rotates accordingly. At this time, the gas self-persuading cutter is guided to withstand the outer diameter of the steel pipe, so that the gas cutting burner and the outer diameter of the steel pipe are kept at a certain distance, so as to avoid the cutting edge being not correct due to the difference in the distance. After the gas chamfering and cutting work is completed, use the feed wheel to make the turning tool longitudinally perform the end face trimming work, and the trimming work at both ends can be carried out at the same time. The mechanical end trimming machine uses fixtures to clamp and position the steel pipe, and the spindle chuck rotates for turning.

(8) Ultrasonic inspection equipment. Ultrasonic inspection of the weld bead is required before and after hydrostatic testing.

(9) Hydraulic testing machine. It consists of a main hydraulic cylinder and a traveling hydraulic cylinder, with a maximum load of 1200t and a maximum pressure of 25MPa. Both ends of the steel pipe are fixed by two test heads: one test head is fixed and the other test head is adjustable. The test head can be replaced according to different pipe diameters.

(10) Drying, rust removal and anti-rust coating on the inner surface of the steel pipe. After the hydrostatic test, the steel pipe cannot work immediately because of the damp temperature, that is, the inner and outer coatings must be dried and derusted. The unit adopts artificial shot blasting derusting method. In order to prevent the inner surface of the steel pipe from rusting during transportation and use, the inner surface of the steel pipe must be coated.

(11) Rust removal treatment on the outer surface of the steel pipe. When the steel pipe is rotating and moving forward on the conveyor table, the shot blasting machine blasts away the rust on the outer surface of the steel pipe. Thereafter, the steel pipes are given an anti-rust coating.