Stainless steel pipes are vital components in diverse industries, renowned for their durability, corrosion resistance, and reliability in fluid transportation systems. Among the various classifications of stainless steel pipes, Schedule 40 stainless steel pipes are prominent for their specific attributes and applications.

1.Schedule 40 stainless steel pipe meaning

"Schedule 40 "is standardized systems used to classify the thickness and dimensions of stainless steel pipes. Established by the American National Standards Institute (ANSI) and the American Society for Testing and Materials (ASTM), the classifications categorize pipes based on their wall thickness and pressure ratings.

"Stainless steel pipe"(S S pipe) is a long, round steel material made of stainless steel. Its main components include chromium, nickel and other metal elements. These elements give stainless steel pipes excellent corrosion resistance and oxidation resistance. Compared with ordinary steel pipes, stainless steel pipes have better anti-corrosion properties in chemical and electrochemical corrosion environments, so they are usually used in high-end decoration, automobile manufacturing, construction engineering and other fields that require corrosion resistance, especially in in the food, beverage and pharmaceutical industries because they do not contaminate these products.

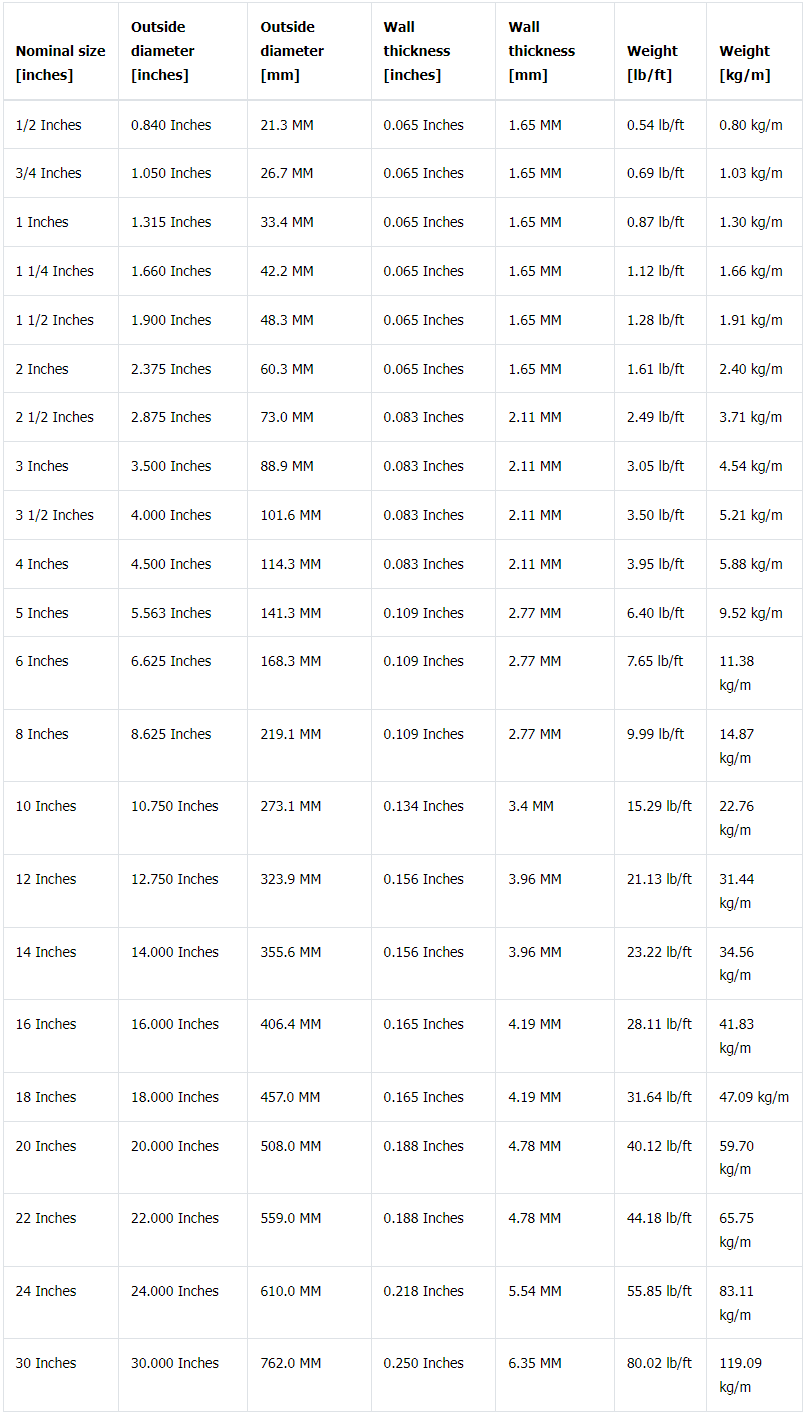

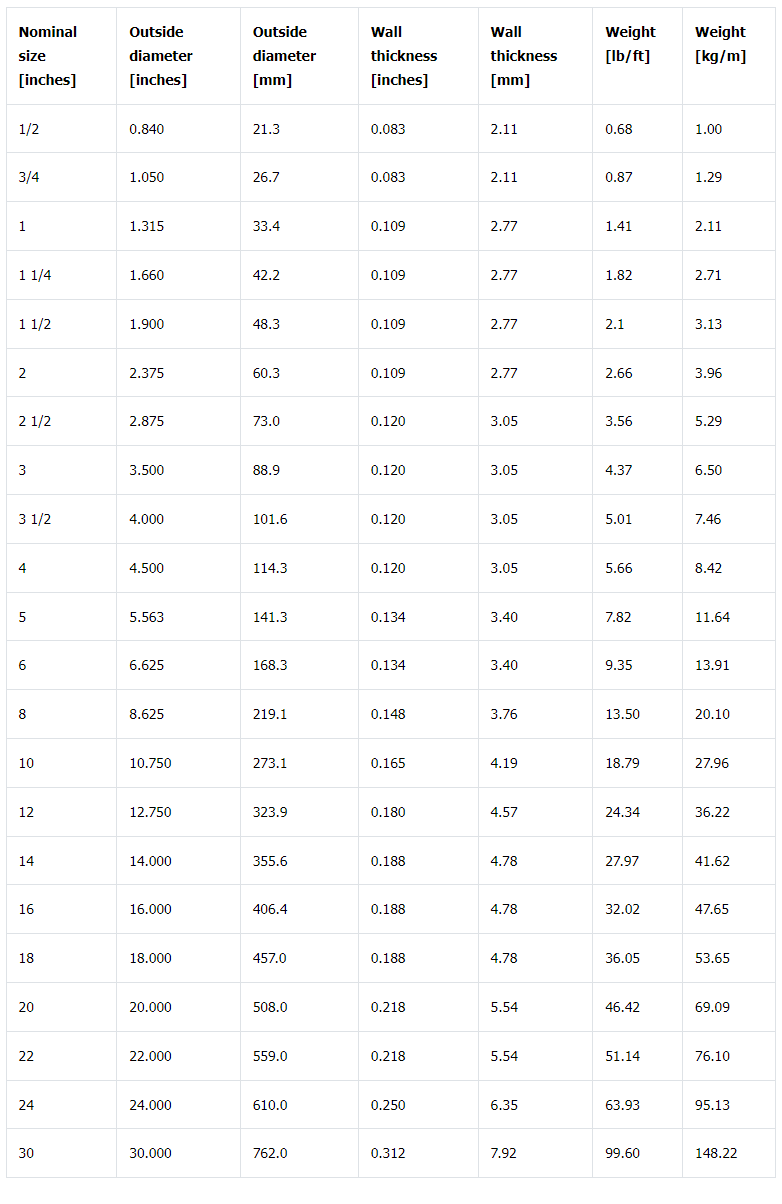

2.SCH 40 stainless steel pipe sizes

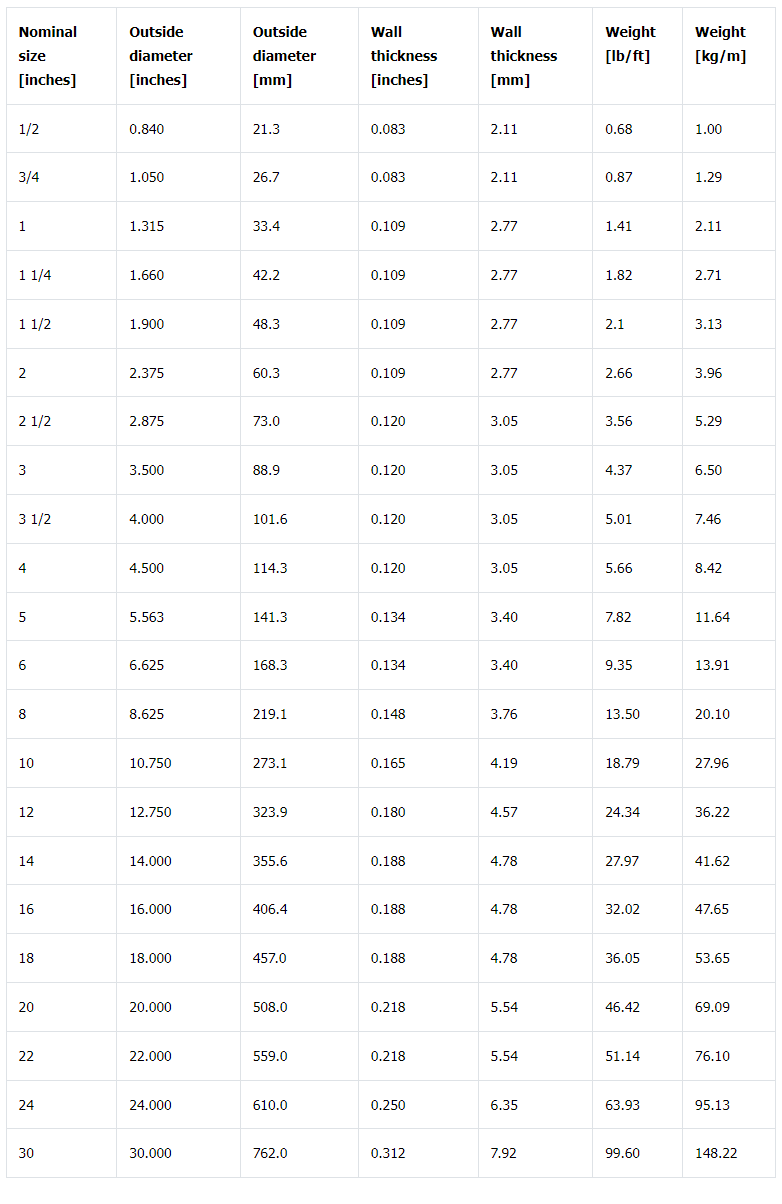

Schedule 40 stainless steel pipes come in a range of nominal sizes, typically ranging from 1/8 inch to 12 inches in diameter. These sizes are standardized according to industry standards, ensuring compatibility and ease of integration into piping systems.

However, it's important to note that actual pipe dimensions may vary slightly depending on the manufacturing process and specific standards adopted by manufacturers.

Common Diameters and Dimensions

(1)Small-Diameter Pipes (1/8 inch to 2 inches):

Small-diameter Schedule 40 stainless steel pipes, ranging from 1/8 inch to 2 inches in diameter, are commonly used in residential, commercial, and light industrial applications. These pipes are suitable for conveying water, gas, and other fluids in plumbing systems , HVAC installations, and general-purpose piping.

(2)Medium-Diameter Pipes (2 inches to 6 inches):

Medium-diameter Schedule 40 stainless steel pipes, ranging from 2 inches to 6 inches in diameter, find extensive use in industrial and commercial settings. They are utilized for a wide range of applications, including chemical processing, food and beverage processing, and water treatment facilities.

(3)Large-Diameter Pipes (6 inches to 12 inches):

Large-diameter Schedule 40 stainless steel pipes, ranging from 6 inches to 12 inches in diameter, are typically employed in heavy industrial applications and infrastructure projects. These pipes are commonly used for transporting large volumes of fluids such as crude oil, natural gas, and industrial chemicals.

In comparison to other schedules such as Schedule 10 and Schedule 80, Schedule 40 stainless steel pipes strike a balance between wall thickness and affordability. While Schedule 10 pipes have thinner walls and are suitable for low-pressure applications, Schedule 80 pipes have thicker walls and are designed for high-pressure environments. Schedule 40 pipes offer a middle ground, making them suitable for a wide range of applications where moderate pressure ratings are required.

Schedule 40 Stainless Steel Pipes Dimension

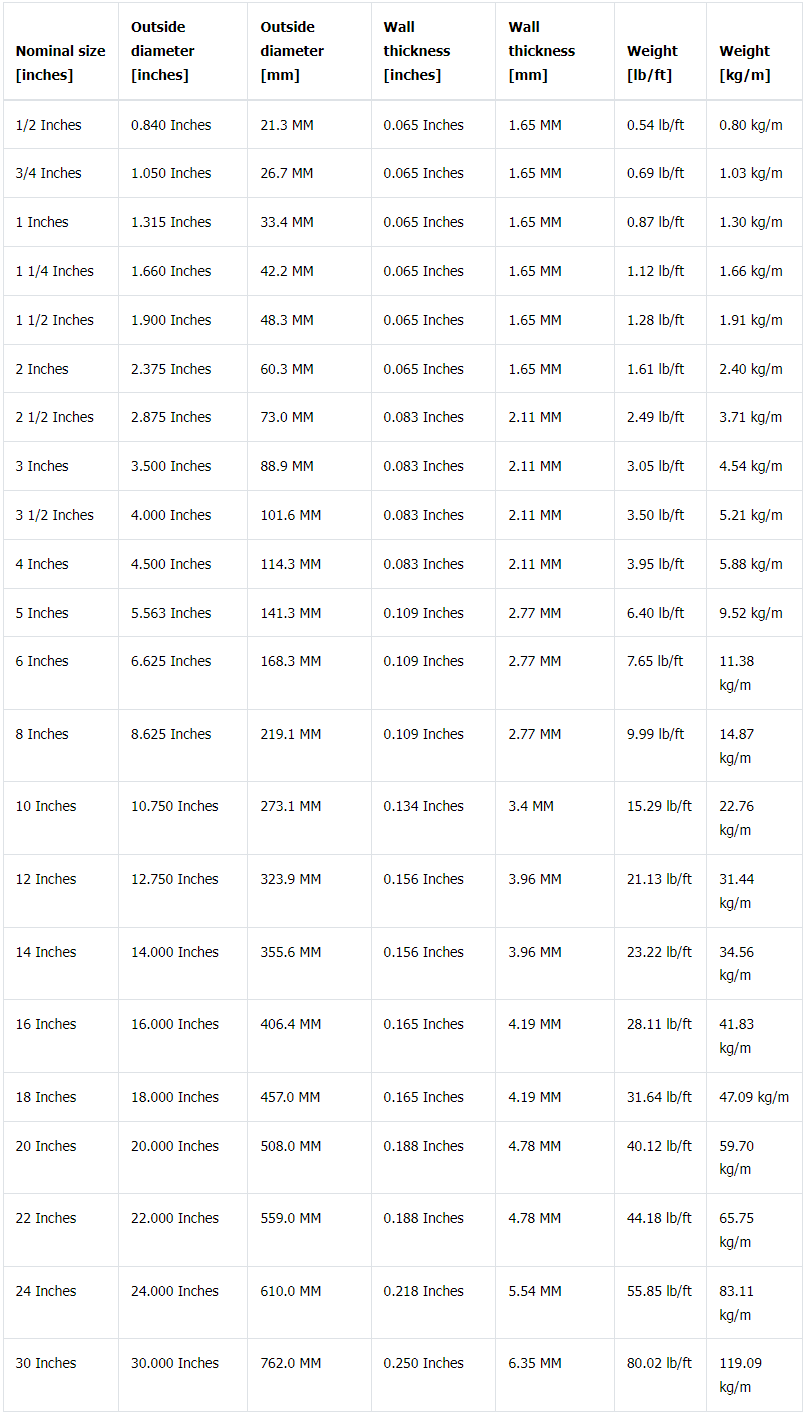

3.Schedule 40 stainless steel pipe thickness

(1)Standard thickness specifications

Schedule 40 stainless steel pipes adhere to standardized thickness specifications set forth by industry standards organizations such as ANSI and ASTM. The nominal wall thickness for Schedule 40 pipes varies depending on the nominal pipe size (NPS).

For example:

For NPS 1/8 to 10, the nominal wall thickness is 0.068 inches (1.73 mm).For NPS 12 and above, the nominal wall thickness is 0.406 inches (10.31 mm).These thickness specifications ensure consistency and uniformity in pipe dimensions, facilitating seamless integration into piping systems and compatibility with various fittings and connectors.

SCH 40 SS Pipe Wall Thickness

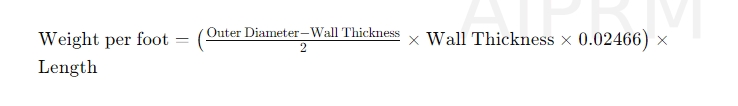

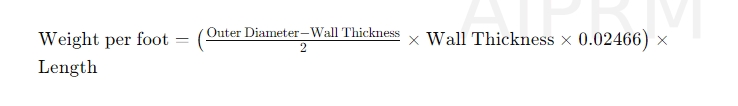

4.Schedule 40 stainless steel pipe weight per foot

The weight per foot of a Schedule 40 stainless steel pipe refers to the mass of the pipe per linear foot of its length. It is determined by the pipe's dimensions (such as diameter and wall thickness) and the density of stainless steel, typically around 0.29 pounds per cubic inch (lb/in³) for austenitic stainless steels commonly used in piping applications.

Where:

Outer Diameter is the outside diameter of the pipe.

Wall Thickness is the thickness of the pipe wall.

Length is the length of the pipe in feet.

Alternatively, various online calculators and software tools are available to simplify the calculation process.

1.Schedule 40 stainless steel pipe meaning

"Schedule 40 "is standardized systems used to classify the thickness and dimensions of stainless steel pipes. Established by the American National Standards Institute (ANSI) and the American Society for Testing and Materials (ASTM), the classifications categorize pipes based on their wall thickness and pressure ratings.

"Stainless steel pipe"(S S pipe) is a long, round steel material made of stainless steel. Its main components include chromium, nickel and other metal elements. These elements give stainless steel pipes excellent corrosion resistance and oxidation resistance. Compared with ordinary steel pipes, stainless steel pipes have better anti-corrosion properties in chemical and electrochemical corrosion environments, so they are usually used in high-end decoration, automobile manufacturing, construction engineering and other fields that require corrosion resistance, especially in in the food, beverage and pharmaceutical industries because they do not contaminate these products.

2.SCH 40 stainless steel pipe sizes

Schedule 40 stainless steel pipes come in a range of nominal sizes, typically ranging from 1/8 inch to 12 inches in diameter. These sizes are standardized according to industry standards, ensuring compatibility and ease of integration into piping systems.

However, it's important to note that actual pipe dimensions may vary slightly depending on the manufacturing process and specific standards adopted by manufacturers.

Common Diameters and Dimensions

(1)Small-Diameter Pipes (1/8 inch to 2 inches):

Small-diameter Schedule 40 stainless steel pipes, ranging from 1/8 inch to 2 inches in diameter, are commonly used in residential, commercial, and light industrial applications. These pipes are suitable for conveying water, gas, and other fluids in plumbing systems , HVAC installations, and general-purpose piping.

(2)Medium-Diameter Pipes (2 inches to 6 inches):

Medium-diameter Schedule 40 stainless steel pipes, ranging from 2 inches to 6 inches in diameter, find extensive use in industrial and commercial settings. They are utilized for a wide range of applications, including chemical processing, food and beverage processing, and water treatment facilities.

(3)Large-Diameter Pipes (6 inches to 12 inches):

Large-diameter Schedule 40 stainless steel pipes, ranging from 6 inches to 12 inches in diameter, are typically employed in heavy industrial applications and infrastructure projects. These pipes are commonly used for transporting large volumes of fluids such as crude oil, natural gas, and industrial chemicals.

In comparison to other schedules such as Schedule 10 and Schedule 80, Schedule 40 stainless steel pipes strike a balance between wall thickness and affordability. While Schedule 10 pipes have thinner walls and are suitable for low-pressure applications, Schedule 80 pipes have thicker walls and are designed for high-pressure environments. Schedule 40 pipes offer a middle ground, making them suitable for a wide range of applications where moderate pressure ratings are required.

Schedule 40 Stainless Steel Pipes Dimension

3.Schedule 40 stainless steel pipe thickness

(1)Standard thickness specifications

Schedule 40 stainless steel pipes adhere to standardized thickness specifications set forth by industry standards organizations such as ANSI and ASTM. The nominal wall thickness for Schedule 40 pipes varies depending on the nominal pipe size (NPS).

For example:

For NPS 1/8 to 10, the nominal wall thickness is 0.068 inches (1.73 mm).For NPS 12 and above, the nominal wall thickness is 0.406 inches (10.31 mm).These thickness specifications ensure consistency and uniformity in pipe dimensions, facilitating seamless integration into piping systems and compatibility with various fittings and connectors.

SCH 40 SS Pipe Wall Thickness

4.Schedule 40 stainless steel pipe weight per foot

The weight per foot of a Schedule 40 stainless steel pipe refers to the mass of the pipe per linear foot of its length. It is determined by the pipe's dimensions (such as diameter and wall thickness) and the density of stainless steel, typically around 0.29 pounds per cubic inch (lb/in³) for austenitic stainless steels commonly used in piping applications.

Where:

Outer Diameter is the outside diameter of the pipe.

Wall Thickness is the thickness of the pipe wall.

Length is the length of the pipe in feet.

Alternatively, various online calculators and software tools are available to simplify the calculation process.