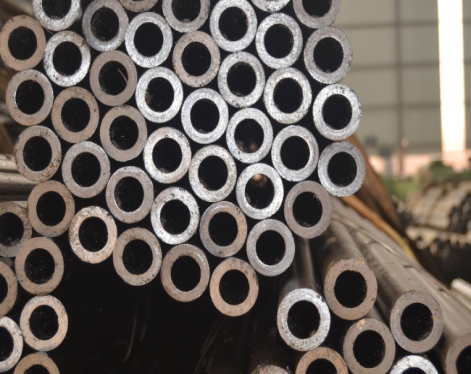

In the complex and critical industrial field of petrochemical industry, seamless steel pipes, as an indispensable basic material, play a vital role. Its unique physical and chemical properties, such as high pressure resistance, high temperature resistance, and corrosion resistance, make it an important link for connecting equipment, conveying fluids, and ensuring production safety. This article will deeply explore the material characteristics, production process, application fields, market status and development trends of seamless steel pipes for petrochemical industry.

Material characteristics and standards:

The materials of seamless steel pipes for petrochemical industry must meet extremely stringent requirements. Common materials include low carbon steel, alloy steel and stainless steel, which have obtained excellent mechanical properties and chemical stability through specific alloy ratios and heat treatment processes. The main steel grades and brands include 20G, 12Cr1MoVG, 15CrMoG in GB 5310, 10, 20, 15CrMo, 12CrMo in GB 9948, and a series of brands specified by international standards such as ASME SA-106M, ASME SA-335M, API 5L, etc. These standards not only specify the chemical composition and mechanical properties of steel pipes, but also put forward clear requirements for their performance at high and low temperatures to ensure that steel pipes can operate stably under extreme working conditions.

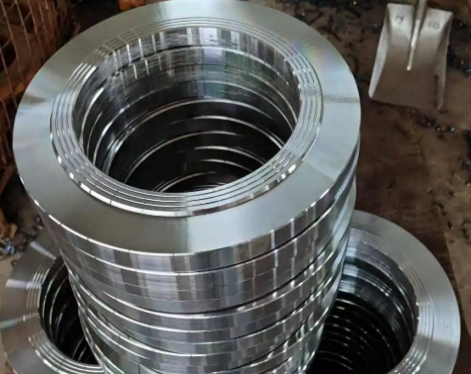

Production process:

The production of seamless steel pipes is a complex and delicate process, mainly including ironmaking, steelmaking, continuous casting, hot rolling, perforation, pipe rolling, heat treatment, finishing and other links. First, iron ore is smelted into pig iron in a blast furnace, and then pig iron and scrap steel and other raw materials are further smelted in a converter or electric furnace to adjust the chemical composition to obtain qualified molten steel. Molten steel is continuously cast into billets through a continuous casting machine, and then undergoes hot rolling, perforation and other processes to form the initial shape of seamless steel pipes. After perforation, the steel pipe needs to undergo multiple rolling passes to achieve the specified size and accuracy. Finally, the internal stress is eliminated through heat treatment to improve the performance of the steel pipe, and then it is subjected to finishing treatments such as cutting, grinding, and inspection to finally obtain qualified seamless steel pipe products.

Application areas:

In the petrochemical industry, seamless steel pipes are widely used. First, in the field of oil drilling, seamless steel pipes are widely used in the manufacture of drilling tools such as drill pipes and casings because of their ability to withstand high temperatures, high pressures and complex geological environments. The stability and durability of these tools are directly related to the success of exploration. Secondly, in terms of oil and gas transportation, seamless steel pipes have become the preferred material for oil and gas pipelines due to their high strength, corrosion resistance and high pressure resistance. Whether it is onshore or offshore oil fields, seamless steel pipes ensure that oil and gas can be safely and efficiently transported to processing plants or oil storage facilities.

In addition, seamless steel pipes also play an important role in the chemical industry. They are used to transport various fluid media, such as chemical raw materials, products, cooling water, etc. These pipes need to withstand high pressure, high temperature and corrosion resistance. At the same time, seamless steel pipes are also used to manufacture various chemical equipment, such as reactors, heat exchangers, storage tanks, etc. The working environment of these equipment is also harsh and has extremely high requirements for material performance. The excellent performance of seamless steel pipes makes it an ideal choice for these equipment.

Market status and development trend:

In recent years, the global seamless steel pipe market has continued to expand, especially driven by the petrochemical industry, and market demand has continued to grow. As an important producer and consumer of seamless steel pipes, China's market size has also continued to grow. However, with the intensification of industry competition, fluctuations in market demand and the strengthening of environmental protection policies, the seamless steel pipe industry is also facing many challenges.

In terms of production capacity, China's seamless steel pipe production capacity has increased year by year, but the capacity utilization rate has remained at a low level. This is mainly due to the intensification of industry competition, insufficient market demand and the impact of environmental protection policies. In the future, mergers and reorganizations in the seamless steel pipe industry will accelerate, and industrial concentration is expected to increase to cope with market competition and environmental protection pressures.

In terms of technology, seamless steel pipe production technology is developing in the direction of high efficiency, energy saving and environmental protection. The introduction and application of high-tech technologies such as digital manufacturing and intelligent production will greatly improve the performance and processing efficiency of products. At the same time, environmental protection investment will also increase to achieve green production and meet global requirements for sustainable development.

In general, the importance of seamless steel pipes as the basic material of the petrochemical industry is self-evident. With the continuous advancement of science and technology and the strengthening of environmental protection policies, the seamless steel pipe industry will usher in new development opportunities and challenges. Through technological innovation, industrial upgrading and green development, seamless steel pipes will better serve the petrochemical industry and contribute to the sustainable development of the industry.

Material characteristics and standards:

The materials of seamless steel pipes for petrochemical industry must meet extremely stringent requirements. Common materials include low carbon steel, alloy steel and stainless steel, which have obtained excellent mechanical properties and chemical stability through specific alloy ratios and heat treatment processes. The main steel grades and brands include 20G, 12Cr1MoVG, 15CrMoG in GB 5310, 10, 20, 15CrMo, 12CrMo in GB 9948, and a series of brands specified by international standards such as ASME SA-106M, ASME SA-335M, API 5L, etc. These standards not only specify the chemical composition and mechanical properties of steel pipes, but also put forward clear requirements for their performance at high and low temperatures to ensure that steel pipes can operate stably under extreme working conditions.

Production process:

The production of seamless steel pipes is a complex and delicate process, mainly including ironmaking, steelmaking, continuous casting, hot rolling, perforation, pipe rolling, heat treatment, finishing and other links. First, iron ore is smelted into pig iron in a blast furnace, and then pig iron and scrap steel and other raw materials are further smelted in a converter or electric furnace to adjust the chemical composition to obtain qualified molten steel. Molten steel is continuously cast into billets through a continuous casting machine, and then undergoes hot rolling, perforation and other processes to form the initial shape of seamless steel pipes. After perforation, the steel pipe needs to undergo multiple rolling passes to achieve the specified size and accuracy. Finally, the internal stress is eliminated through heat treatment to improve the performance of the steel pipe, and then it is subjected to finishing treatments such as cutting, grinding, and inspection to finally obtain qualified seamless steel pipe products.

Application areas:

In the petrochemical industry, seamless steel pipes are widely used. First, in the field of oil drilling, seamless steel pipes are widely used in the manufacture of drilling tools such as drill pipes and casings because of their ability to withstand high temperatures, high pressures and complex geological environments. The stability and durability of these tools are directly related to the success of exploration. Secondly, in terms of oil and gas transportation, seamless steel pipes have become the preferred material for oil and gas pipelines due to their high strength, corrosion resistance and high pressure resistance. Whether it is onshore or offshore oil fields, seamless steel pipes ensure that oil and gas can be safely and efficiently transported to processing plants or oil storage facilities.

In addition, seamless steel pipes also play an important role in the chemical industry. They are used to transport various fluid media, such as chemical raw materials, products, cooling water, etc. These pipes need to withstand high pressure, high temperature and corrosion resistance. At the same time, seamless steel pipes are also used to manufacture various chemical equipment, such as reactors, heat exchangers, storage tanks, etc. The working environment of these equipment is also harsh and has extremely high requirements for material performance. The excellent performance of seamless steel pipes makes it an ideal choice for these equipment.

Market status and development trend:

In recent years, the global seamless steel pipe market has continued to expand, especially driven by the petrochemical industry, and market demand has continued to grow. As an important producer and consumer of seamless steel pipes, China's market size has also continued to grow. However, with the intensification of industry competition, fluctuations in market demand and the strengthening of environmental protection policies, the seamless steel pipe industry is also facing many challenges.

In terms of production capacity, China's seamless steel pipe production capacity has increased year by year, but the capacity utilization rate has remained at a low level. This is mainly due to the intensification of industry competition, insufficient market demand and the impact of environmental protection policies. In the future, mergers and reorganizations in the seamless steel pipe industry will accelerate, and industrial concentration is expected to increase to cope with market competition and environmental protection pressures.

In terms of technology, seamless steel pipe production technology is developing in the direction of high efficiency, energy saving and environmental protection. The introduction and application of high-tech technologies such as digital manufacturing and intelligent production will greatly improve the performance and processing efficiency of products. At the same time, environmental protection investment will also increase to achieve green production and meet global requirements for sustainable development.

In general, the importance of seamless steel pipes as the basic material of the petrochemical industry is self-evident. With the continuous advancement of science and technology and the strengthening of environmental protection policies, the seamless steel pipe industry will usher in new development opportunities and challenges. Through technological innovation, industrial upgrading and green development, seamless steel pipes will better serve the petrochemical industry and contribute to the sustainable development of the industry.