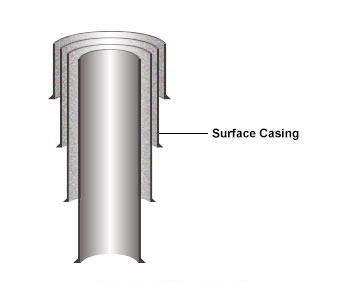

1.What is a surface casing?

Surface casing is a type of OCTG casing. It is the outermost casing in the oil and gas well casing program. After drilling, the bedrock below the surface soil layer is drilled, or the surface casing is drilled to a certain depth. . It is a casing that is used to prevent the collapse of the loose layer on the surface of the wellbore, isolate the upper freshwater layer from being polluted by drilling work, and install a wellhead blowout preventer. The penetration depth should be determined based on the depth of the loose formation and the rupture pressure gradient of the upper formation. The diameter of the surface casing is determined based on the number of casing layers and the diameter of the conductor casing.

2.Function of surface casing

The functions of this kind of steel pipe:

- Isolating the upper aquifer to prevent surface water and surface groundwater from seeping into the wellbore;

- Protecting the wellhead and reinforce the well wall of the topsoil layer;

- For those who continue to drill and encounter high-pressure oil and gas layers, Blowout preventers are installed on the surface casing to prevent blowouts.

3.Surface casing vs production casing

Surface casing and conductor casing are both types of casing used in oil and gas drilling operations, but they serve different purposes.

(1)Surface casing

Surface casing is the first casing that is installed during the drilling process.Its primary purpose is to protect freshwater aquifers and prevent any contamination from the drilling fluids or formation fluids.

It is usually set relatively shallow, typically to a depth where freshwater zones are found.

Surface casing also provides structural integrity to the wellbore during the initial drilling stages, helping to prevent collapse or blowouts.

(2)Production casing

Production casing is installed after the surface casing and is used to isolate the production zone(s) from other formations.Its primary purpose is to provide a conduit for the oil or gas to flow from the reservoir to the surface.Production casing is typically set deeper into the wellbore, penetrating the hydrocarbon-bearing formations.It is designed to withstand the pressures and temperatures encountered during production operations.In summary, surface casing is primarily for environmental protection and wellbore stability during initial drilling, while production casing is specifically designed to facilitate the production of oil or gas from the reservoir.

4.Surface casing vs intermediate casing

Surface casing and intermediate casing are both types of casing used in oil and gas drilling, but they are employed at different depths and stages of the drilling process.

(1)Surface casing

Surface casing is the first casing string set during drilling operations.It is usually installed to relatively shallow depths, typically to protect freshwater aquifers and prevent contamination.

Surface casing provides structural integrity to the wellbore and serves as a barrier between the drilling fluids and surrounding formations.

Its primary purpose is environmental protection and wellbore stability during the initial stages of drilling.

(2)Intermediate casing

Intermediate casing is set at depths between the surface casing and production casing.It is installed after drilling through intermediate formations or zones that may pose stability or pressure challenges.

The intermediate casing provides additional structural support to the wellbore and helps isolate problematic formations.

Its main functions include maintaining wellbore stability, preventing fluid influx, and protecting against gas or pressure kicks.

Intermediate casing also facilitates the subsequent drilling process by providing a stable platform for further drilling operations.

In summary, while surface casing is installed near the surface to protect freshwater aquifers and ensure initial wellbore stability, intermediate casing is set at intermediate depths to address specific geological challenges encountered during drilling and to prepare the wellbore for further operations.

5.What is the usual size of the surface casing used in drilling?

The size of surface casing used in drilling operations can vary depending on factors such as the specific drilling project, regulatory requirements, and geological conditions. However, a common size for surface casing is typically in the range of 13 3/8 inches to 20 inches in diameter. This size allows for adequate protection of freshwater aquifers and provides sufficient structural integrity to the wellbore during the initial stages of drilling. Additionally, the diameter of the surface casing is chosen to accommodate the subsequent casing strings that will be installed deeper into the wellbore as drilling progresses.

Previous:Piling hammers and pile drivers

Next:Conductor casing