1. Structural Support in Construction

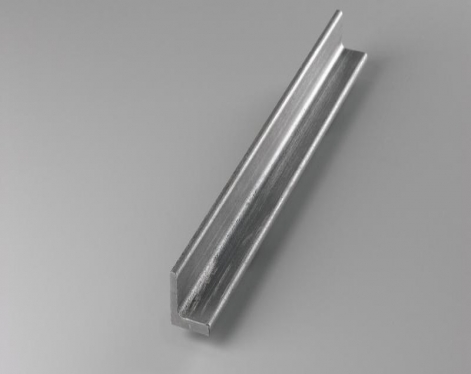

(1) Steel Angle for Lintel / Angle Iron for Lintel

In current home renovation projects, besides cast-in-place reinforced concrete, steel angles are often overlooked as materials for door lintels. The specifications for steel angles used as door lintels are generally 50MM x 5MM, and they are typically required to undergo hot-dip galvanizing treatment. Note that when constructing door lintels, it is essential to incorporate steel reinforcement bars within them, even if steel angles are used as load-bearing components.Although steel angles have a certain load-bearing capacity and the door lintels use lightweight bricks, relying solely on steel angles and lightweight bricks may still be insufficient to bear all the loads, posing a risk of structural failure. Especially in the event of natural disasters such as earthquakes, this structural design could become a significant safety hazard. Therefore, to ensure the stability and safety of the structure, it is imperative to include steel reinforcement bars in the door lintels to enhance their overall load-bearing capacity and seismic performance.

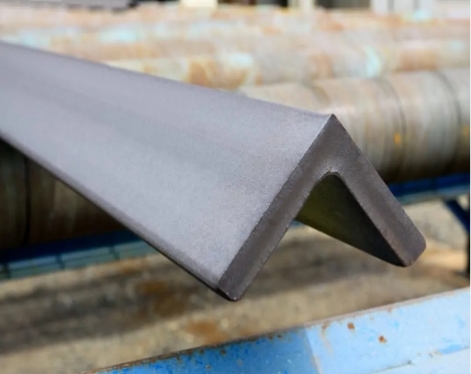

(2) Angle Iron for Brick Ledge

Angle iron can be used as a brick ledge to provide structural support and stability for brickwork. The specific size of angle iron needed depends on the load-bearing requirements and the design specifications of the project. Typically, angle irons used for brick support should be chosen based on the weight of the bricks, the span of the ledge, and the overall structural integrity needed, ensuring that they are adequate to prevent any risk of collapse or deformation.

2. Transportation and Support

(1)Angle Iron for Trailer Frame

Utility trailers often utilize angle iron due to its strength and cost-effectiveness, with typical sizes ranging from 3x3 to 4x4 inches depending on the load capacity and design requirements. When comparing angle iron to rectangular tubing for utility trailers, angle iron generally offers better resistance to torsion and is easier to weld, making it a popular choice for trailer construction. However, some builders may opt for rectangular tubing for its sleek appearance and potentially higher load-bearing capacity. As for pipe top trailers, they are often considered superior due to their greater rigidity and reduced flexing, which can enhance the overall durability and stability of the trailer, although this can vary based on specific construction methods and materials used.

3. Safety and Protection

When it comes to the fabrication and installation of fence posts, angle iron is one of the key materials. The appropriate angle for cutting fence post angle iron is typically 90 degrees to ensure that the posts stand upright and stable. To adjust or straighten fence posts, specialized tools such as fence post straighteners can be used. In terms of material selection, angle iron is often considered ideal for making fence posts due to its structural strength and cost-effectiveness. Regarding burial depth, wrought iron or angle iron fence posts generally need to be buried at least 24 to 36 inches underground to ensure their stability and safety under various weather conditions.

4. Home and Daily Use

(1) Angle Iron for Shelving

Steel angles provide a sturdy support frame and enhance stability in bookshelf design, ensuring that the shelves can safely bear the weight of books. When designing and using steel angle shelves, it is important to choose the appropriate steel angle size and thickness to match the expected load-bearing requirements, ensuring that all welding or bolt connections are secure to prevent structural loosening due to poor connections. At the same time, considering aesthetics and safety, the surface treatment of steel angles is also important, such as painting or electroplating, which can increase aesthetics and prevent rusting. In addition, the steel frame of the bookshelf should be designed as simple and clear as possible to facilitate cleaning and maintenance, while avoiding sharp edges to ensure safe use. In this way, steel angles not only enhance the practicality of the bookshelf but also enhance its aesthetics and safety, becoming a part of indoor decoration and extending the overall service life.(2) Angle Iron for Bed Frame

Steel angles play a primary role in supporting and stabilizing the structure of bed frames. They are commonly used to construct the frame of the bed, including the four corners, sides, and foot of the bed, ensuring the solidity and load-bearing capacity of the entire bed frame. The high strength and durability of steel angles enable the bed frame to withstand the weight and pressure of daily use while providing uniform support to prevent the mattress from sagging or deforming. Moreover, the metallic properties of steel angles also help prevent the bed frame from dampness or rot, increasing the service life and ease of maintenance. Through precise cutting, drilling, and welding or bolt connections, steel angles can form a stable and aesthetically pleasing bed frame structure.

5. Industrial Equipment and Machinery

(1) Reaction Towers

Reaction towers are equipment or devices used for chemical reactions, typically in industrial production chemical reaction processes. Steel angles are mainly used in reaction towers to construct the structural framework of the tower, support beams and columns, and to make equipment brackets and connectors, providing necessary support and stability, while enhancing the tower's resistance to wind loads and seismic capabilities, ensuring the solidity and safety of the overall structure, facilitating maintenance and inspection by operators.

(2) Machinery Manufacturing

Steel angles play a crucial role in the field of machinery manufacturing, especially in constructing the framework and providing structural support for machinery. Their applications are extensive, covering a range of equipment from industrial machinery such as cranes and mixers, to agricultural machinery such as tractors and harvesters, to construction machinery such as tower cranes and excavators. The high strength and durability of steel angles make them an ideal choice for the support structure of these machines, ensuring stability and safety during operation.Additionally, the ease of processing and cost-effectiveness of steel angles also make them widely used in the manufacturing of transportation equipment such as trucks and trailers, energy equipment such as wind turbines, food processing machinery such as packaging machines, medical equipment such as operating tables, textile machinery such as looms, electronic equipment such as server racks, and automated equipment such as robotic arms. Steel angles can be connected with other structural components through welding, bolt connections, etc., facilitating assembly and disassembly, making the manufacturing and maintenance of machinery more convenient. At the same time, steel angles can be galvanized, coated, etc., to improve their corrosion resistance and extend the service life of machinery, especially important when used in harsh environments.

The flexibility and aesthetics of steel angles are also one of the reasons for their popularity. Their cross-sectional sizes are diverse, and the appropriate steel angle size can be chosen according to the specific needs of the machinery, providing customized solutions, while their simple appearance is easy to coordinate with other components, improving the overall aesthetics of the machinery. Therefore, whether in improving the performance and reliability of machinery or in reducing manufacturing costs, steel angles are an economical and practical structural material.