Low temperature carbon steel plates refers to carbon steel used in low temperature environments, and its carbon content is generally between 0.1% and 0.25%. Low temperature carbon steel has good low temperature toughness and welding performance, and is widely used in low temperature containers, pipelines, low temperature equipment and other fields.

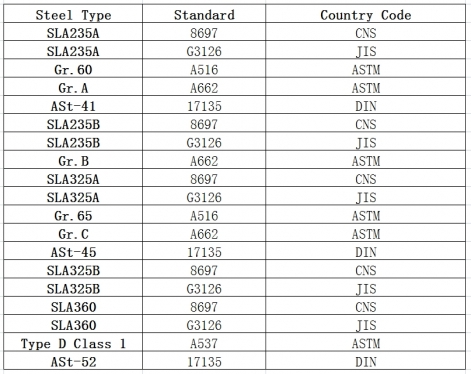

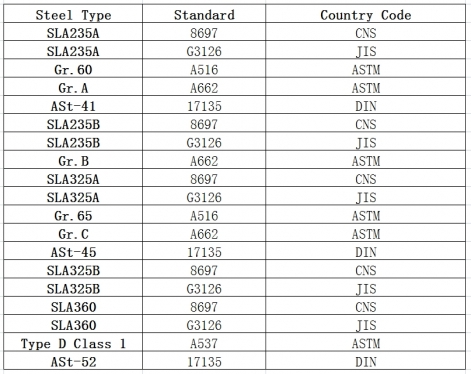

1. Carbon steel plates for pressure vessels for low temperature service

2.Applications of LTCS plates

(1)Pressure Vessels

LTCS plates are commonly used in the fabrication of pressure vessels plate that operate at low temperatures, such as Liquefied Natural Gas (LNG) tanks, liquid oxygen tanks, and other cryogenic storage equipment.

(2)Chemical and Petroleum Industries

In the chemical processing and petroleum refining industries, LTCS plates are used to construct reactors, heat exchangers, pipelines, and other equipment that must maintain performance at low temperatures.

(3)Construction Industry

In construction projects in polar or cold regions, LTCS plates can be used for structural support and roofing systems to ensure structural stability under extreme low temperatures.

(4)Transportation

LTCS plates are used in the manufacturing of tankers for transporting liquefied gases, refrigerated transport vehicles, and other transportation equipment that operates at low temperatures.

(5)Energy Industry

LTCS plates are key materials in the production, storage, and transportation of Liquefied Natural Gas (LNG) and Liquefied Petroleum Gas (LPG).

(6)Food Processing

In facilities that require low-temperature storage and transportation for frozen food processing and storage, LTCS plates are used to construct cold storage facilities and refrigeration equipment.

(7)Medical and Scientific Research

LTCS plates can be used to manufacture cryogenic experimental equipment, such as liquid nitrogen storage tanks and cryogenic experimental chambers.

(8)Marine Engineering

In marine platforms and other marine structures, LTCS plates can be used to manufacture equipment and structures that operate in cold seawater.

(10)Aerospace

In some aerospace applications that require operation at extreme low temperatures, LTCS plates can also be used to manufacture components and structures.

3.Features of LTCS plates

LTCS plates are commonly used in the fabrication of pressure vessels plate that operate at low temperatures, such as Liquefied Natural Gas (LNG) tanks, liquid oxygen tanks, and other cryogenic storage equipment.

(2)Chemical and Petroleum Industries

In the chemical processing and petroleum refining industries, LTCS plates are used to construct reactors, heat exchangers, pipelines, and other equipment that must maintain performance at low temperatures.

(3)Construction Industry

In construction projects in polar or cold regions, LTCS plates can be used for structural support and roofing systems to ensure structural stability under extreme low temperatures.

(4)Transportation

LTCS plates are used in the manufacturing of tankers for transporting liquefied gases, refrigerated transport vehicles, and other transportation equipment that operates at low temperatures.

(5)Energy Industry

LTCS plates are key materials in the production, storage, and transportation of Liquefied Natural Gas (LNG) and Liquefied Petroleum Gas (LPG).

(6)Food Processing

In facilities that require low-temperature storage and transportation for frozen food processing and storage, LTCS plates are used to construct cold storage facilities and refrigeration equipment.

(7)Medical and Scientific Research

LTCS plates can be used to manufacture cryogenic experimental equipment, such as liquid nitrogen storage tanks and cryogenic experimental chambers.

(8)Marine Engineering

In marine platforms and other marine structures, LTCS plates can be used to manufacture equipment and structures that operate in cold seawater.

(10)Aerospace

In some aerospace applications that require operation at extreme low temperatures, LTCS plates can also be used to manufacture components and structures.

3.Features of LTCS plates

| Feature/Attribute | Description |

|---|---|

| Chemical Composition | Carbon content: Up to 0.25% Manganese: 0.35-1.00% Silicon: 0.20-0.50% Phosphorus: 0.035-0.040% Sulfur: 0.040-0.080% Other elements like Vanadium and Chromium: Up to 1.60% (depending on the grade of steel) |

| Alloying Elements | Nickel, Manganese, Vanadium, Molybdenum, Chromium, etc., to improve toughness and corrosion resistance |

| Properties | High strength Good durability Good plasticity Excellent corrosion resistance Suitable for outdoor applications |

| Applications | Construction industry Oil and gas industry Chemical plants |

| Common Grades | ASTM A516 Gr70, ASTM A36, ASME SA-387/SA-387M, EN 10028-2 P265GH |

| Size Range | Thickness: 3 to 500 mm Width: Up to 4 meters |

| Cost and Availability | Affordable and offers excellent thermal stability |

| Mechanical Properties | Offers a remarkable combination of strength, resilience, and flexibility, making it highly sought-after for various industrial applications |