What is H-beam?

Advantages of H-beam

1. High strength, good rigidity, and large load-bearing capacity: The special cross-sectional shape of H-shaped steel enables effective friction and fixing between the upper and lower flanges and the web, giving it high strength and rigidity, capable of bearing large loads, and is widely used in large-scale building structures and bridge projects. For example, when constructing large-span buildings such as large stadiums and exhibition halls, H-shaped steel can be used as the main load-bearing structure to ensure the stability and safety of the building.

2. A wide variety of products with high efficiency: H-beam products are available in a variety of specifications and are classified in various ways according to flange width, purpose, production method, etc., to meet the needs of different projects. Moreover, it has wide flanges, thin webs, and is flexible to use. It can save 15% - 20% of metal when used in truss structures. When manufacturing mechanical parts, engineers can choose appropriate specifications of H-shaped steel according to the stress conditions of the parts, which can not only ensure the performance of the parts but also save material costs.

3. Good economy and long service life: The cross-sectional shape of H-shaped steel is economical and reasonable, with excellent mechanical properties. During rolling, each point on the cross-section has uniform extension and small internal stress, which can save metal, lighten the building structure by 30% - 40%, and reduce construction costs. And it generally undergoes anti-corrosion, fire-proof and other treatments, has good durability, reduces subsequent maintenance costs, and extends its service life. Like some industrial plants, the use of H-shaped steel as structural material not only reduces construction costs, but also allows long-term and stable use without the need for frequent maintenance.

Disadvantages of H-beam

Although H-shaped steel has outstanding advantages, it also has some disadvantages. Due to its material and specifications, it is relatively heavy, which requires larger and more professional transportation equipment during transportation, increasing transportation costs; During installation, large lifting equipment and more manpower are required, which increases the difficulty and cost of installation. At the same time, its cross-sectional shape is fixed as an "H" shape, which may not meet the needs of some buildings with special shapes or structural requirements, such as uniquely shaped art venues, irregular bridges, etc. In addition, during the production process of H-shaped steel, the surface may be uneven and rough, such as rolling marks, iron oxide scale, etc., which requires additional surface treatment, such as grinding, rust removal, painting, etc., which increases the processing steps and costs.

The difference between H-beam and angle steel

In terms of load-bearing capacity and rigidity, H-shaped steel has high strength, good rigidity and large load-bearing capacity due to its special cross-sectional shape; Angle steel also has good strength and load-bearing capacity, but it is not as rigid as H-shaped steel. When subjected to pressure or bending moment, it is more likely to bend and deform than H-shaped steel.

In terms of variety, H-beam products are rich in specifications and can be classified into various categories according to flange width, purpose, production method, etc., to meet the needs of different projects; There are relatively few types of angle steels, and there are certain limitations in meeting the needs of special building structures. In terms of economy and service life, the cross-section shape of H-shaped steel is economical and reasonable, which can save metal and reduce construction costs. After anti-corrosion and fire-proof treatment, it has good durability and long service life. The production cost of angle steel is relatively low, but from the perspective of overall use, due to the limitations of its rigidity and load-bearing capacity, it may be used in large quantities in some large projects, the overall cost may not be low, and its service life is relatively short.

Read more: Differences in the Process of Angle Steel and H-beam Steel

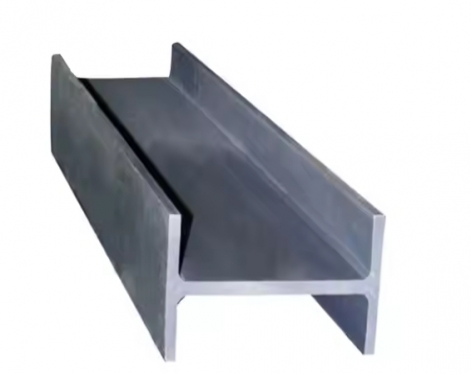

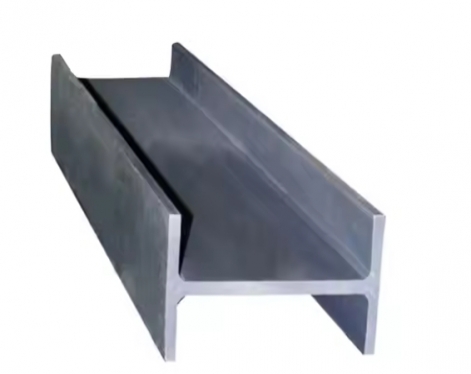

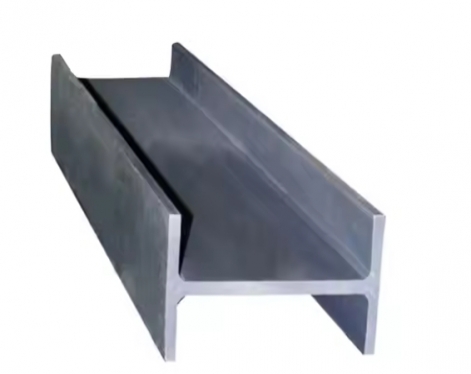

H-beam is an economical section profile, named because its cross section is similar to the capital Latin letter "H". It is also called universal steel beam, wide flange I-beam or parallel flange I-beam. Its cross section usually consists of two parts: the web (waist) and the flange (edge). Viewed from the side, it looks like an I-beam, but unlike ordinary I-beams, the inner and outer sides of the flanges of H-beams are almost parallel, and the ends are at right angles.

Advantages of H-beam

1. High strength, good rigidity, and large load-bearing capacity: The special cross-sectional shape of H-shaped steel enables effective friction and fixing between the upper and lower flanges and the web, giving it high strength and rigidity, capable of bearing large loads, and is widely used in large-scale building structures and bridge projects. For example, when constructing large-span buildings such as large stadiums and exhibition halls, H-shaped steel can be used as the main load-bearing structure to ensure the stability and safety of the building.

2. A wide variety of products with high efficiency: H-beam products are available in a variety of specifications and are classified in various ways according to flange width, purpose, production method, etc., to meet the needs of different projects. Moreover, it has wide flanges, thin webs, and is flexible to use. It can save 15% - 20% of metal when used in truss structures. When manufacturing mechanical parts, engineers can choose appropriate specifications of H-shaped steel according to the stress conditions of the parts, which can not only ensure the performance of the parts but also save material costs.

3. Good economy and long service life: The cross-sectional shape of H-shaped steel is economical and reasonable, with excellent mechanical properties. During rolling, each point on the cross-section has uniform extension and small internal stress, which can save metal, lighten the building structure by 30% - 40%, and reduce construction costs. And it generally undergoes anti-corrosion, fire-proof and other treatments, has good durability, reduces subsequent maintenance costs, and extends its service life. Like some industrial plants, the use of H-shaped steel as structural material not only reduces construction costs, but also allows long-term and stable use without the need for frequent maintenance.

Disadvantages of H-beam

Although H-shaped steel has outstanding advantages, it also has some disadvantages. Due to its material and specifications, it is relatively heavy, which requires larger and more professional transportation equipment during transportation, increasing transportation costs; During installation, large lifting equipment and more manpower are required, which increases the difficulty and cost of installation. At the same time, its cross-sectional shape is fixed as an "H" shape, which may not meet the needs of some buildings with special shapes or structural requirements, such as uniquely shaped art venues, irregular bridges, etc. In addition, during the production process of H-shaped steel, the surface may be uneven and rough, such as rolling marks, iron oxide scale, etc., which requires additional surface treatment, such as grinding, rust removal, painting, etc., which increases the processing steps and costs.

The difference between H-beam and angle steel

H-beam and angle steel are both common steel materials, but they differ in many aspects. From the perspective of structural shape, H-shaped steel is "H"-shaped, with two horizontal surfaces and one vertical surface, and can withstand forces in multiple directions; Angle steel is "L" shaped, with only one horizontal surface and one vertical surface, and is more suitable for bearing unidirectional forces.

In terms of load-bearing capacity and rigidity, H-shaped steel has high strength, good rigidity and large load-bearing capacity due to its special cross-sectional shape; Angle steel also has good strength and load-bearing capacity, but it is not as rigid as H-shaped steel. When subjected to pressure or bending moment, it is more likely to bend and deform than H-shaped steel.

In terms of variety, H-beam products are rich in specifications and can be classified into various categories according to flange width, purpose, production method, etc., to meet the needs of different projects; There are relatively few types of angle steels, and there are certain limitations in meeting the needs of special building structures. In terms of economy and service life, the cross-section shape of H-shaped steel is economical and reasonable, which can save metal and reduce construction costs. After anti-corrosion and fire-proof treatment, it has good durability and long service life. The production cost of angle steel is relatively low, but from the perspective of overall use, due to the limitations of its rigidity and load-bearing capacity, it may be used in large quantities in some large projects, the overall cost may not be low, and its service life is relatively short.

Read more: Differences in the Process of Angle Steel and H-beam Steel