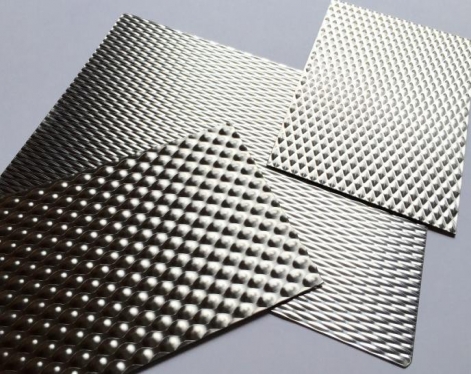

Stainless steel embossed sheet is a mental stainless steel plate pressed by embossing process. The embossing process is that the metal sheet is physically extruded through large-scale CNC mechanical equipment and precision pattern molds to make the steel sheet surface appear with various exquisite concave and convex patterns, commonly known as metal embossed sheet.

Compared with other decorative materials, stainless steel embossed sheet has the advantages of corrosion resistance, scratch resistance, wear resistance, strong decorative effect, anti-fingerprint, etc. It is generally suitable for indoor ceiling, decorative elevator wall, architectural decoration, building curtain wall, etc.

Common stainless steel embossed sheet materials are 304 steel and 304L steel. Some areas with special requirements will also use 316 steel with better corrosion resistance. The thickness is 0.6mm-1.5mm. The width is generally 0.5m, 0.8m, 1m, 1.22m, 1.5m, and the length can be customized.

① Good environmental adaptability. Waterproof and fireproof, it will not change color after long-term storage; it is acid-alkali-salt resistant, so it is not easy to corrode in the acid-alkali-salt environment of the air. Compared with traditional exterior wall insulation boards, it has better cold resistance and heat insulation performance.

② Good safety performance. No radiation, easy to clean, earthquake-resistant and crack-resistant, longer service life; it has very good impact and compression resistance. When used on the outside of the building, it can greatly reduce its impact on the building; especially on some light steel structure buildings, embossed boards are particularly suitable.

③ Good decorative effect. The three-dimensional sense presented by the concave and convex texture on the decorative panel is unparalleled, the visual effect is obvious, clean, bright, unique, and has a typical metal fashion art sense. And there are a variety of colors to choose from, and the space effect can be made more colorful by customizing the texture.

④ Strong plasticity. Due to the good toughness of the metal, various shapes can be made using welding, grinding, bending, polishing and other processes.

⑤ Maintenance-free. Anti-scratch and no fingerprints.

⑥ Environmentally friendly secondary use. Because the original color of metal is stable, not easy to dissolve and oxidize, it can be recycled and has a certain value preservation. In addition, there is no chemical interference in the reinforcement process, and the impact on the environment is relatively small. Using it to replace wood can protect the environment and reduce the felling of wood.

⑦ High-end customization is possible. Metal embossed plates have many pattern structures, and can provide customized services. According to consumer requirements, unique patterns can be designed to meet the needs of the majority of users.

Mold stamping is to frequently stamp one pattern after another on the plate, so the depth and three-dimensional sense of the mold stamping pattern are stronger than the roll embossing.

② Roll embossing: roll processing, average force

Roll embossing is the whole roll through the unwinding machine, embossing roller, and winding machine. Therefore, the flatness of the stamped plate is better than that of the stamped plate.

① Single-sided embossing

Process: Through roller pressing mechanical equipment, under the working condition of a single cylindrical pattern mold, the stainless steel coil is extruded to make the front side present a concave and convex pattern and the back side is flat.

Features: It has the characteristics of scratch resistance, impact resistance, dirt resistance, easy cleaning, and anti-sticking.

Production thickness: 0.8-2.0mm, width below 1.22m, and length can be customized (within 6m).

② Double-sided embossing

Process: Through roller pressing mechanical equipment, under the working condition of two cylindrical pattern molds, the stainless steel sheet is double-sidedly extruded to make the front and back sides present a concave and convex pattern, commonly known as double-sided embossing.

Features: It has the characteristics of scratch resistance, impact resistance, dirt resistance, easy cleaning, and anti-sticking.

Production thickness: 0.8-2.0mm, width below 1.22m, and length can be customized (within 6m).

③ Water ripple surface

Features: It forms a shimmering effect under the refraction of light, commonly known as water ripples. The stainless steel water ripple plate is made by stamping the pattern on the stainless steel plate.

Production thickness: 0.8-5.0mm, width below 1.5m, length can be customized (within 6m).

In addition, the surface coloring process of stainless steel can bring different colors to stainless steel, making the metal more colorful, and can also effectively improve the wear resistance and corrosion resistance of the product.

The commonly used surface coloring methods for stainless steel embossed plates are: electrolytic coloring, retro aging, and vacuum titanium plating. The colors produced are mainly: champagne gold, rose gold, gold, black, blue, bronze, bronze, etc.

1. Characteristics of stainless steel embossed sheet

Compared with other decorative materials, stainless steel embossed sheet has the advantages of corrosion resistance, scratch resistance, wear resistance, strong decorative effect, anti-fingerprint, etc. It is generally suitable for indoor ceiling, decorative elevator wall, architectural decoration, building curtain wall, etc.

(1) Product specifications

Common stainless steel embossed sheet materials are 304 steel and 304L steel. Some areas with special requirements will also use 316 steel with better corrosion resistance. The thickness is 0.6mm-1.5mm. The width is generally 0.5m, 0.8m, 1m, 1.22m, 1.5m, and the length can be customized.

(2) Material characteristics

① Good environmental adaptability. Waterproof and fireproof, it will not change color after long-term storage; it is acid-alkali-salt resistant, so it is not easy to corrode in the acid-alkali-salt environment of the air. Compared with traditional exterior wall insulation boards, it has better cold resistance and heat insulation performance.② Good safety performance. No radiation, easy to clean, earthquake-resistant and crack-resistant, longer service life; it has very good impact and compression resistance. When used on the outside of the building, it can greatly reduce its impact on the building; especially on some light steel structure buildings, embossed boards are particularly suitable.

③ Good decorative effect. The three-dimensional sense presented by the concave and convex texture on the decorative panel is unparalleled, the visual effect is obvious, clean, bright, unique, and has a typical metal fashion art sense. And there are a variety of colors to choose from, and the space effect can be made more colorful by customizing the texture.

④ Strong plasticity. Due to the good toughness of the metal, various shapes can be made using welding, grinding, bending, polishing and other processes.

⑤ Maintenance-free. Anti-scratch and no fingerprints.

⑥ Environmentally friendly secondary use. Because the original color of metal is stable, not easy to dissolve and oxidize, it can be recycled and has a certain value preservation. In addition, there is no chemical interference in the reinforcement process, and the impact on the environment is relatively small. Using it to replace wood can protect the environment and reduce the felling of wood.

⑦ High-end customization is possible. Metal embossed plates have many pattern structures, and can provide customized services. According to consumer requirements, unique patterns can be designed to meet the needs of the majority of users.

2. Types of stainless steel embossed plates

(1) Classification according to production process

① Mold stamping: plate processing, local forceMold stamping is to frequently stamp one pattern after another on the plate, so the depth and three-dimensional sense of the mold stamping pattern are stronger than the roll embossing.

② Roll embossing: roll processing, average force

Roll embossing is the whole roll through the unwinding machine, embossing roller, and winding machine. Therefore, the flatness of the stamped plate is better than that of the stamped plate.

(2) Classification by appearance

① Single-sided embossingProcess: Through roller pressing mechanical equipment, under the working condition of a single cylindrical pattern mold, the stainless steel coil is extruded to make the front side present a concave and convex pattern and the back side is flat.

Features: It has the characteristics of scratch resistance, impact resistance, dirt resistance, easy cleaning, and anti-sticking.

Production thickness: 0.8-2.0mm, width below 1.22m, and length can be customized (within 6m).

② Double-sided embossing

Process: Through roller pressing mechanical equipment, under the working condition of two cylindrical pattern molds, the stainless steel sheet is double-sidedly extruded to make the front and back sides present a concave and convex pattern, commonly known as double-sided embossing.

Features: It has the characteristics of scratch resistance, impact resistance, dirt resistance, easy cleaning, and anti-sticking.

Production thickness: 0.8-2.0mm, width below 1.22m, and length can be customized (within 6m).

③ Water ripple surface

Features: It forms a shimmering effect under the refraction of light, commonly known as water ripples. The stainless steel water ripple plate is made by stamping the pattern on the stainless steel plate.

Production thickness: 0.8-5.0mm, width below 1.5m, length can be customized (within 6m).

In addition, the surface coloring process of stainless steel can bring different colors to stainless steel, making the metal more colorful, and can also effectively improve the wear resistance and corrosion resistance of the product.

The commonly used surface coloring methods for stainless steel embossed plates are: electrolytic coloring, retro aging, and vacuum titanium plating. The colors produced are mainly: champagne gold, rose gold, gold, black, blue, bronze, bronze, etc.