On-line normalization of steel pipes (seamless pipes or welded pipes) is a new process developed in recent years. From the perspective of metallurgy, it is a heat treatment process, that is, deformation normalizing. It is to cool the steel pipe after continuous rolling to below the recrystallization temperature on a small cooling bed, and then enter the reheating furnace.

Read more

The selection of equipment for the steel pipe heat treatment production line should be based on the product outline, that is to say, the appropriate equipment should be selected according to the type of steel pipe (seamless pipe or welded pipe), specification, output, etc.

Read more

During the welding process, if the interlayer temperature is too high, the grains will be elongated and t8/5 will be increased. It cannot be normalized during on-site welding, and the original strength and toughness of the steel pipe will be lost. Therefore, the interlayer temperature must be strictly controlled during the welding process to prevent grain elongation.

Read more

Lamellar tearing usually occurs in the welding of thick-walled seamless pipes. The main reason is that the MnS inclusions in the steel pipe develop into cracks and then tear under the tensile stress perpendicular to the plate surface, resulting in low plastic failure of the structure.

Read more

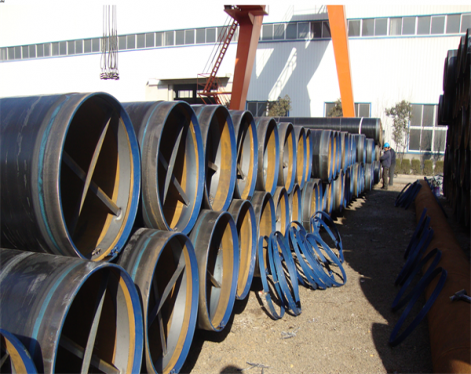

Submerged arc welded straight seam steel pipe (LSAW pipe) is a kind of steel pipe used in oil and gas pipelines with large consumption and high reliability. The forming unit forms include UOE, RBE, JCOE, etc.

Read more

Petroleum pipe is a seamless steel pipe suitable for furnace tubes, heat exchangers and pipes in petroleum refineries. Petroleum pipe is a long strip of steel with a hollow section and no joints around it, and petroleum cracking pipe is an economical cross-section steel.

Read more